Self-protection flux-cored wire for downward welding and horizontal position welding

A flux-cored wire, self-protection technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of uneven weld bead, poor welding effect, reduce weld plasticity, etc., and achieve good plasticity. and strength, excellent welding performance and less spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

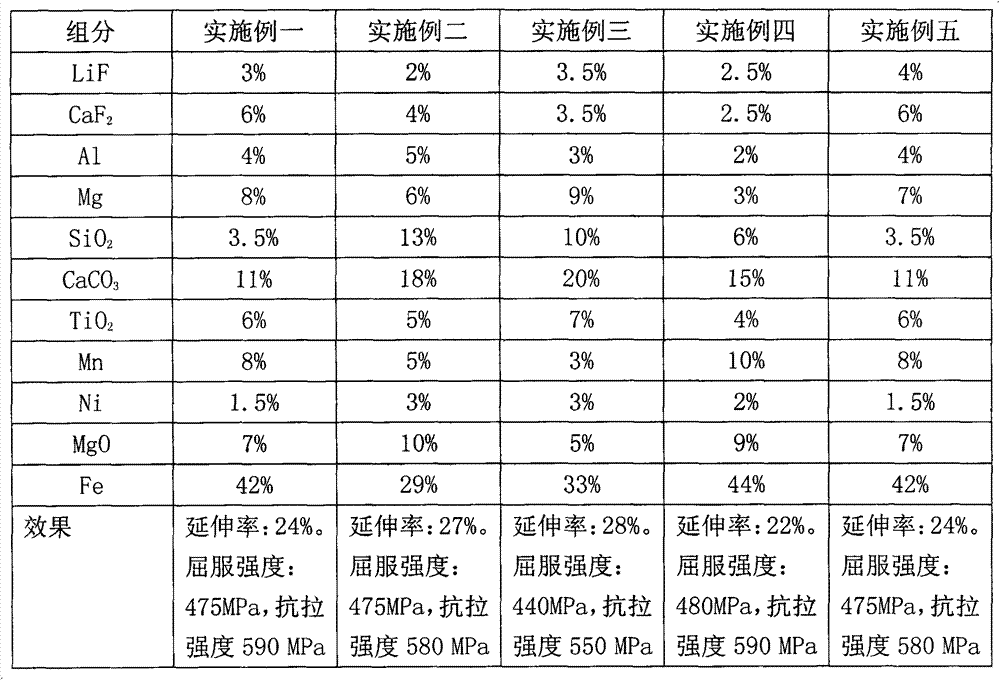

[0024] The self-shielding flux-cored wire used for flat welding and horizontal welding, the key is: the flux core of the self-shielding flux-cored wire is composed of 3-10% manganese, 1-4% nickel, 1-5% aluminum %, magnesium 1-9%, carbonate 10-20%, fluoride 1-10%, titanium dioxide 1-7%, magnesium oxide 7-10%, silicon dioxide 3-13%, iron powder 25-50% .

[0025] The flux core of the self-shielding flux-cored wire is composed of 6-9% manganese, 2-3% nickel, 3-5% aluminum, 4-7% magnesium, 12-17% carbonate, fluorine Compound 3-7%, titanium dioxide 3-5%, magnesium oxide 7-10%, silicon dioxide 7-10%, iron powder 25-50%.

[0026] The ratio of the flux core to the total weight of the welding wire is 12-26%.

[0027] Described carbonate is one of barium carbonate or calcium carbonate.

[0028] The fluorides include LiF and CaF 2 , and LiF and CaF 2 The weight ratio is 1: (1-2). Recommended welding parameters:

[0029] Welding current: 180-260A

[0030] Welding voltage: 20-22V

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com