High-molecular organic polymer template synthesized compound pore structure molecular sieve and preparation method thereof

A technology of molecular sieves and polymers, applied in the direction of crystalline aluminosilicate zeolites, etc., can solve the problems of complex synthesis conditions such as the price of template agents, and achieve the effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Synthesis of composite pore structure ZSM-5 with high molecular organic amine polymer and TPABr (tetrapropylammonium bromide) as composite template

[0045] Synthetic raw materials: polyethyleneimine, TPABr, ethyl orthosilicate, Al 2 (SO 4 ) 3 (Aluminum Sulfate), NaOH (Sodium Hydroxide)

[0046] Specific synthesis steps: first dissolve 3gTPABr in 72g water, and mix 0.75gAl 2 (SO 4 ) 3 And add 0.72g NaOH, after the solution is clarified, add 23.5g tetraethyl orthosilicate and continue to stir, use NaOH to adjust the pH to 12, add 1g polyethyleneimine after aging at room temperature for 6 hours, continue to stir until the mixture is uniform The obtained gel was put into a polytetrafluoroethylene-lined stainless steel reactor and reacted at 200°C for 1 day. After the final sample was washed, dried at 110°C, and then calcined at 800°C for 5 hours, a ZSM-5 molecular sieve with a composite pore structure was obtained.

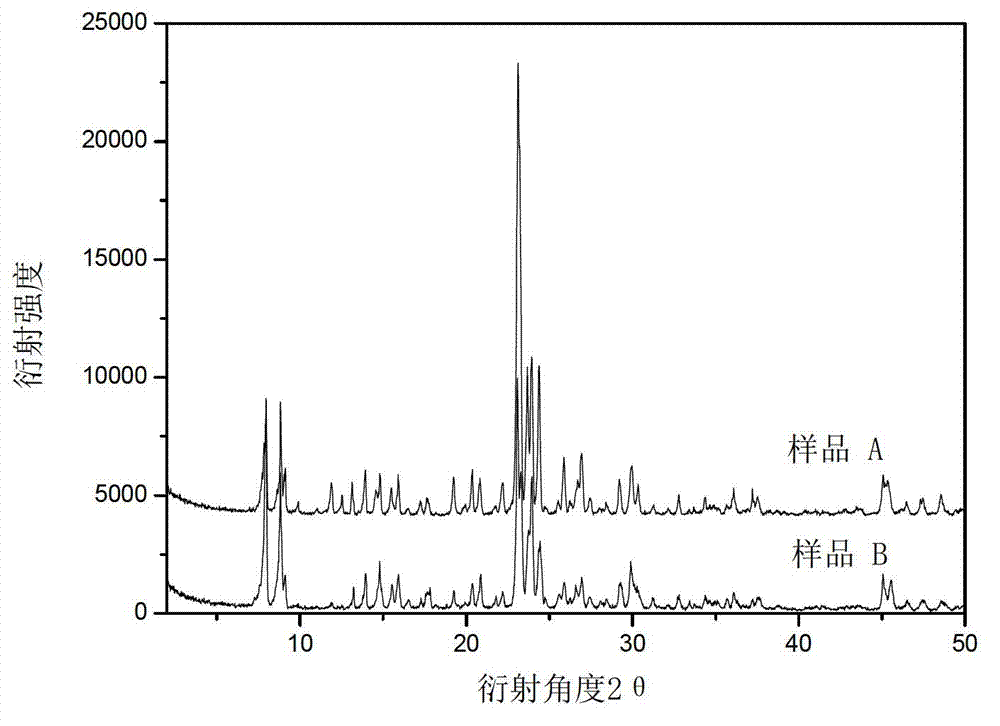

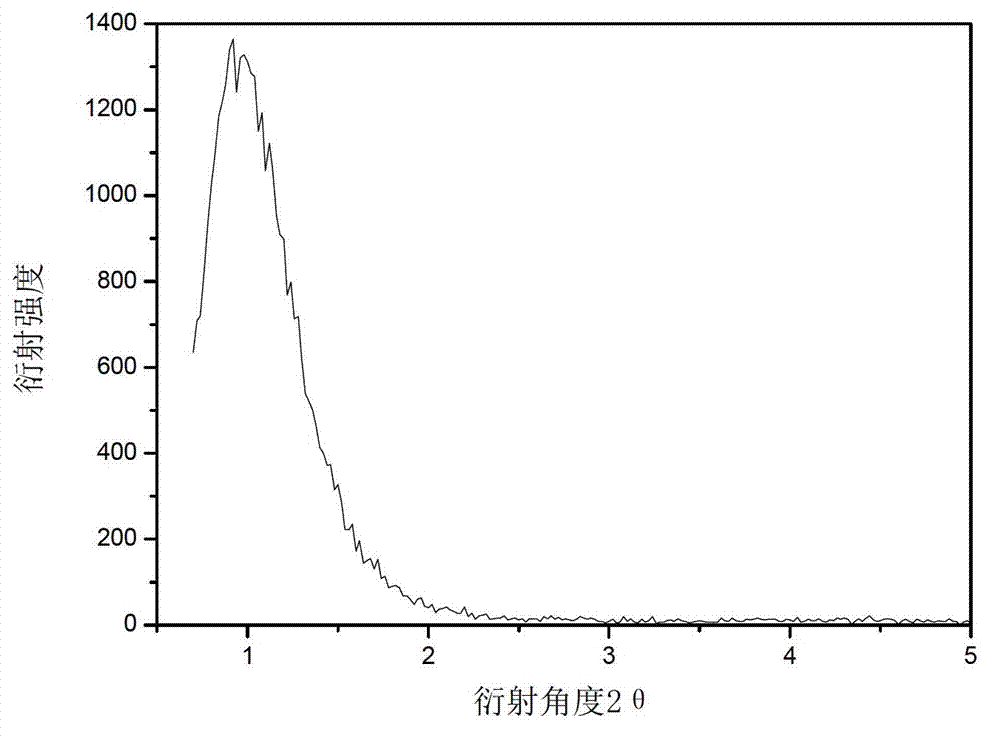

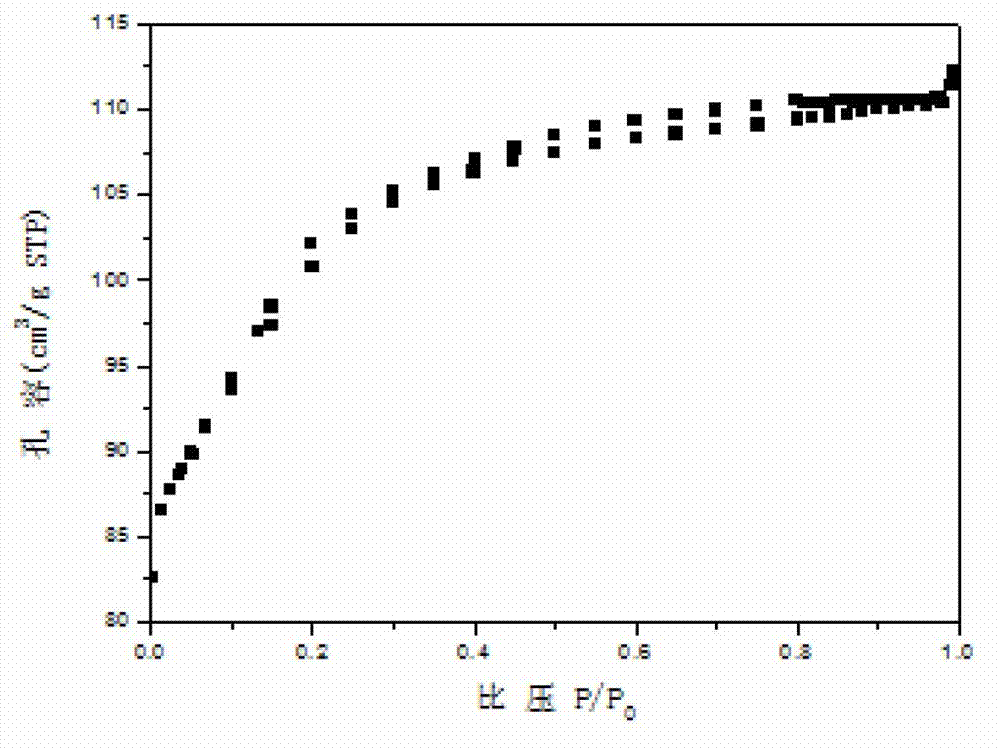

[0047] Molecular sieves with high cr...

Embodiment 2

[0048] Example 2: Synthesis of composite pore structure ZSM-5 with high molecular organic amine polymer and TPABr (tetrapropylammonium bromide) as composite template

[0049] Synthetic raw materials: polyethyleneimine, TPABr, ethyl orthosilicate, Al 2 (SO 4 ) 3 (Aluminum Sulfate), NaOH (Sodium Hydroxide)

[0050] Specific synthesis steps: firstly dissolve 8.43gTPABr in 72g water, and mix 0.75gAl 2 (SO 4 ) 3 And add 0.72g NaOH, after the solution is clarified, add 23.5g tetraethyl orthosilicate and continue to stir, use NaOH to adjust the pH to 13, add 5g polyethyleneimine after aging at room temperature for 6 hours, continue to stir until the mixture is uniform The obtained gel was put into a polytetrafluoroethylene-lined stainless steel reactor and reacted at 180°C for 3 days. After the final sample was washed, dried at 110°C, and calcined at 300°C for 18 hours, a ZSM-5 molecular sieve with a composite pore structure was obtained.

Embodiment 3

[0051] Embodiment 3: Synthesis of compound pore structure L-type molecular sieve with macromolecule organic amine polymer

[0052] Synthetic raw materials: polyethyleneimine, silica sol (30% mass fraction), NaAlO 2 (sodium metaaluminate), NaOH (sodium hydroxide), KOH (potassium hydroxide)

[0053] Concrete synthetic steps:

[0054] First weigh 3.2gNaOH, 5.2gKOH and 1.4gNaAlO 2 , dissolved in 40.8g of water and stirred, after the solution was clarified, 49.4g of silica sol with a mass fraction of 30% was added and continued to stir, and 2g of polyethyleneimine was added and stirred until evenly mixed, and then the obtained gel was loaded into PTFE An ethylene-lined stainless steel autoclave was reacted at 150°C for 80 hours. After the final sample was washed, dried at 110° C., and then calcined at 300° C. for 12 hours, an L-type molecular sieve with a composite pore structure was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com