Method for producing ultrawhite aluminum hydroxide and by-products from high-alumina fly ash by using high-temperature alkaline leaching

A high-alumina fly ash and aluminum hydroxide technology, applied in the field of metallurgy, can solve problems such as difficulty in realizing large-scale industrial production, large alkali consumption, and large discharge of silicon-calcium slag, so as to improve comprehensive utilization value and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

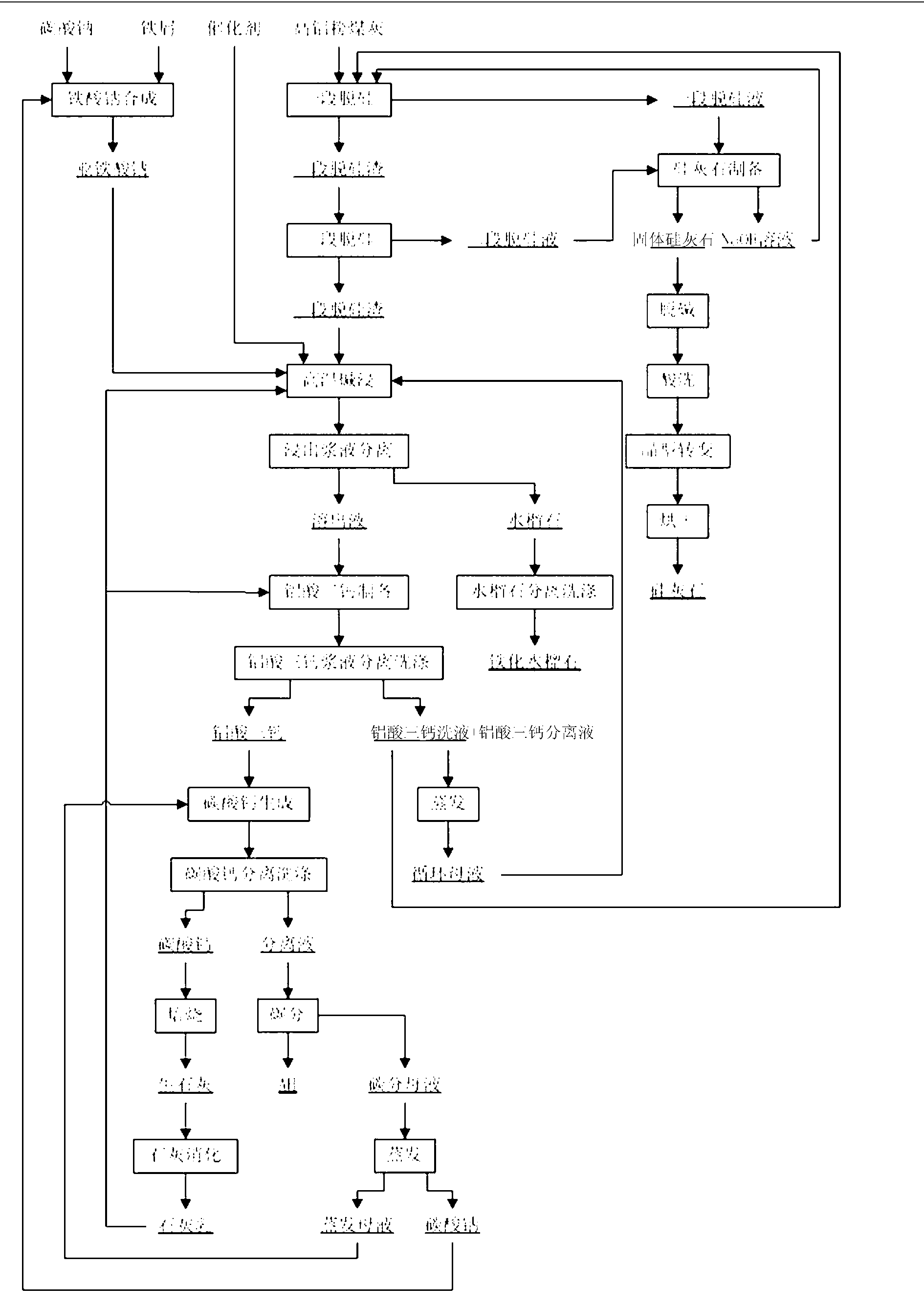

Image

Examples

Embodiment 1

[0020] (1) Ball mill the high-aluminum fly ash to a particle size below 200 mesh, mix it evenly with the circulating NaOH solution and tricalcium aluminate washing solution, and the Al in the mixed solution 2 0 3 The concentration is 13~14g / L, αk=30, desiliconization at 80℃ for 1.0h ,Obtain one-stage desiliconization liquid and one-stage desiliconization slag, and then carry out two-stage medium-pressure desiliconization on the first-stage desiliconization slag under the conditions of 160°C and 0.27MPa for 0.8h to obtain two-stage desiliconization slag and two-stage desiliconization liquid. The first-stage desiliconization liquid is mixed with the second-stage desiliconization liquid to obtain a mixed liquid, and milk of lime is added to the mixed liquid for causticizing reaction. The amount of milk of lime added is 38% of the volume of the desiliconized liquid after mixing to obtain a wollastonite slurry. The wollastonite slurry is separated and washed to obtain solid wollas...

Embodiment 2

[0028] (1) Ball mill the high-aluminum fly ash to a particle size below 200 mesh, mix it evenly with the circulating NaOH solution and tricalcium aluminate washing solution, and the Al in the mixed solution 2 0 3 The concentration is 13~14g / L, αk=30, desiliconization at 90℃ for 0.8h , Obtain one-stage desiliconization liquid and one-stage desiliconization slag, and then carry out two-stage medium-pressure desiliconization on the first-stage desiliconization slag under the condition of 130°C and 0.62MPa for 0.5h to obtain two-stage desiliconization slag and two-stage desiliconization liquid, The first-stage desiliconization liquid is mixed with the second-stage desiliconization liquid to obtain a mixed liquid, and milk of lime is added to the mixed liquid for causticizing reaction. The amount of milk of lime added is 40% of the volume of the desiliconized liquid after mixing to obtain a wollastonite slurry. The wollastonite slurry is separated and washed to obtain solid wollas...

Embodiment 3

[0036] (1) Ball mill the high-aluminum fly ash to a particle size below 200 mesh, mix it evenly with the circulating NaOH solution and tricalcium aluminate washing solution, and the Al in the mixed solution 2 0 3 Concentration is 13~14g / L, αk=30, Al in the mixture 2 o 3 The concentration is 13~14g / L, αk=30, desiliconization at 105℃ for 0.5h , Obtain one-stage desiliconization liquid and one-stage desiliconization slag, then carry out second-stage medium-pressure desiliconization on the first-stage desiliconization slag under the condition of 150°C and 0.51MPa for 1.0h to obtain two-stage desiliconization slag and second-stage desiliconization liquid, The first-stage desiliconization liquid is mixed with the second-stage desiliconization liquid to obtain a mixed liquid, and milk of lime is added to the mixed liquid for causticizing reaction. The amount of milk of lime added is 42% of the volume of the desiliconized liquid after mixing to obtain a wollastonite slurry. The wol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com