Method for preparing MU5 regenerated solid brick by building waste

A technology for recycling solid bricks and construction waste, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as waste of land resources and environmental pollution, and achieve the effect of weight reduction and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

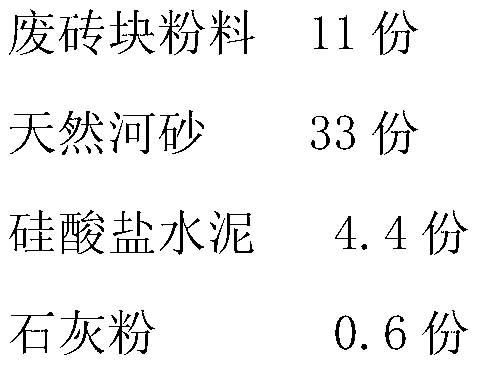

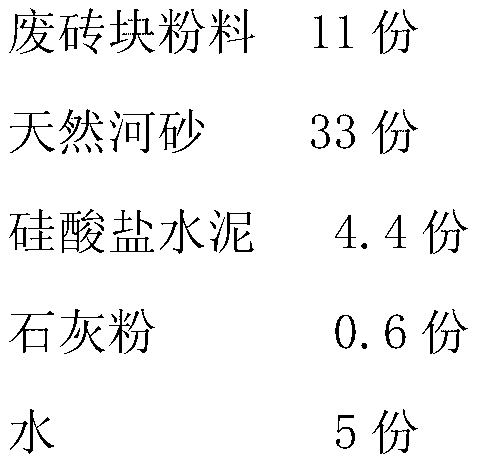

[0020] The method for preparing MU5 regenerated solid bricks from construction wastes of the present invention uses aggregates formed by crushing and screening construction waste waste bricks and natural river sand as fine aggregates, and adds a certain amount of lime powder, cement and an appropriate amount of water to prepare Recycled and environmentally friendly solid bricks with a strength level of 5Mpa. The composition of the raw materials and the mass parts of each raw material are: 11 parts of broken brick powder, 33 parts of natural river sand, 4.4 parts of Portland cement, 0.6 part of lime powder and 5 parts of water.

[0021] The preparation steps of MU5 recycled solid bricks are:

[0022] Pick out waste bricks from construction waste, put them into a crusher and crush them, and screen out bricks with a particle size greater than 4.75mm to obtain recycled fine aggregate waste brick powder.

[0023] Sieve the natural river sand to remove the natural river sand with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com