Molecular imprinting composite membrane for organophosphorus pesticide detection and application of membrane

An organophosphorus pesticide, molecular imprinting technology, applied in other chemical processes, color/spectral property measurement, chemical instruments and methods, etc., can solve the problems such as difficulty in obtaining antigens, stability, reproducibility and service life to be improved, etc. Achieving the effect of simple preparation method and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

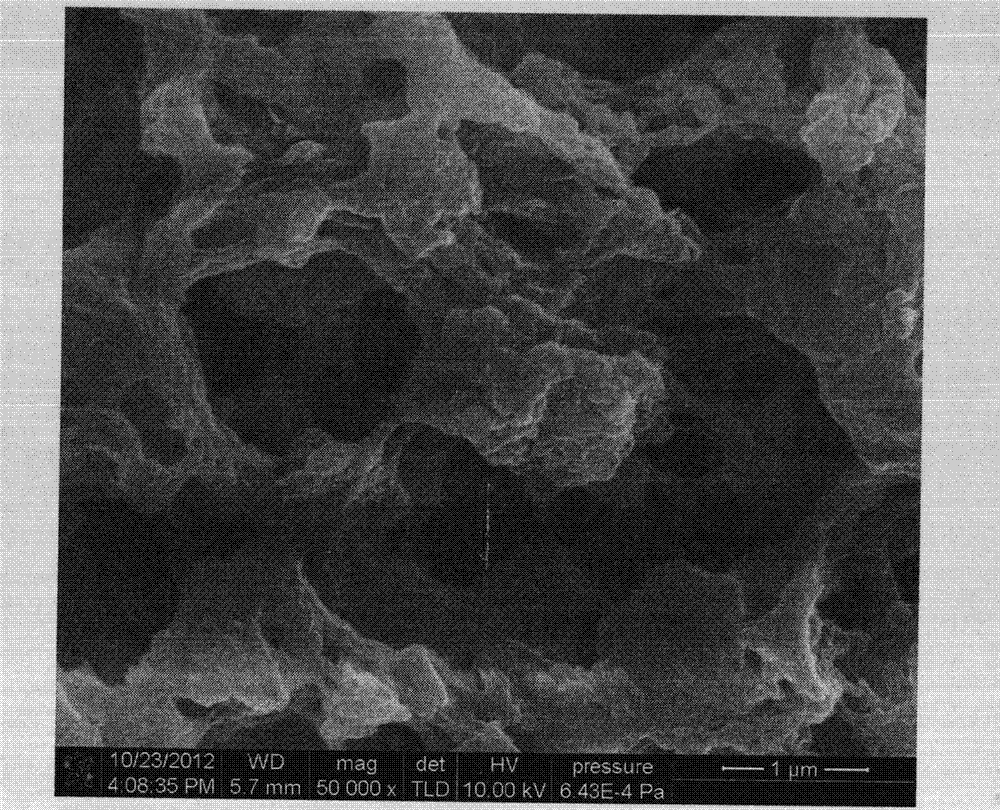

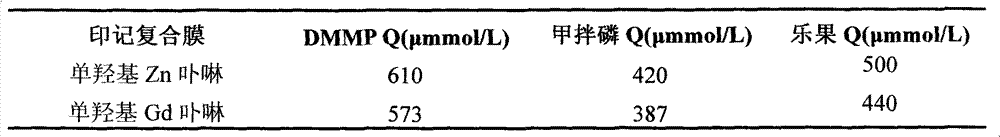

[0022] (1) Preparation of pre-reaction solution: Dissolve 658 mg of functional monomer monohydroxyzinc porphyrin and 5.1 μL of template molecule dimethyl methylphosphonate (DMMP) in 10 mL of chloroform, and then add 35.7 μL of cross-linking agent B Glycol dimethacrylate (EGDMA) and 25 mg initiator azobisisobutyronitrile (AIBN). Nitrogen gas was passed through the reaction mixture for 10 minutes, followed by ultrasonic degassing for 10 minutes. Polyvinylidene fluoride microporous filter membrane (PVDF membrane, its scanning electron micrograph is as follows figure 2 Shown) into the above mixture, put it in the refrigerator and let it stand overnight.

[0023] (2) Membrane production: Take out the polyvinylidene fluoride microporous filter membrane in the mixed solution the next day and place it between two glass slides, irradiate with a 365nm ultraviolet lamp to initiate polymerization, turn over every 20 minutes, and irradiate for 12 hours Finally, the glass slides are sepa...

example 2

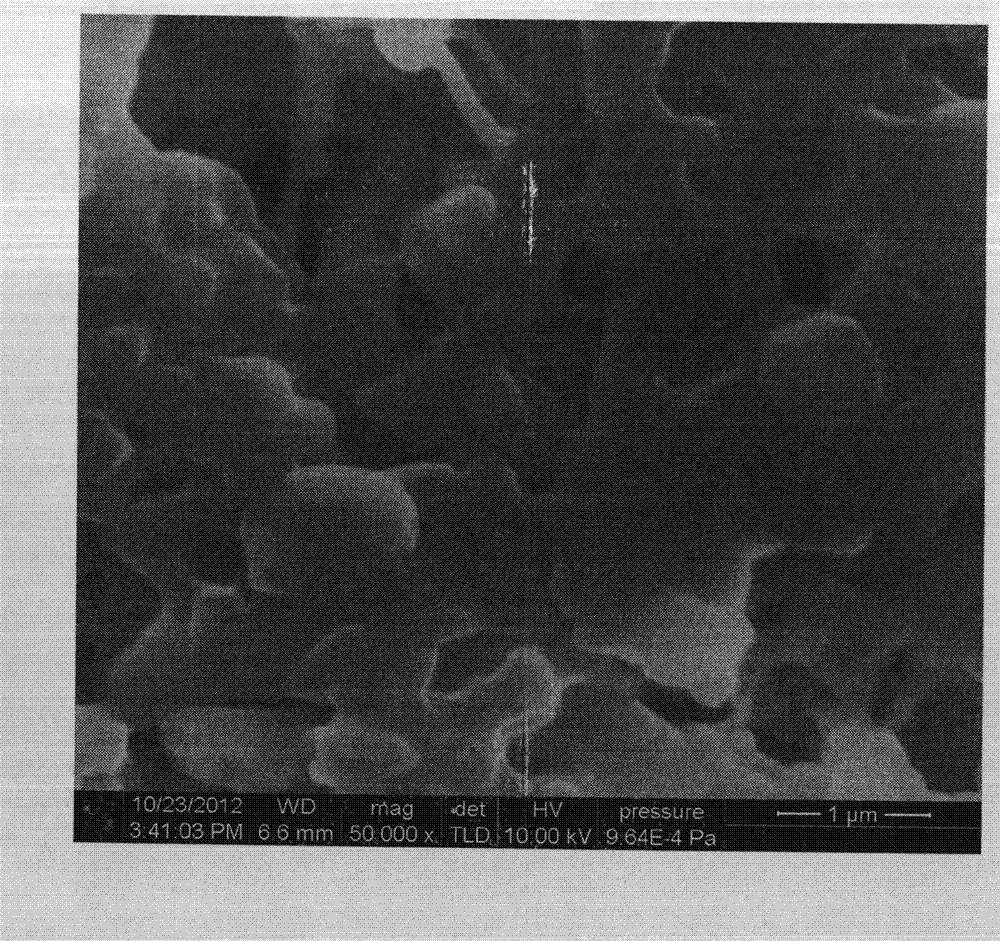

[0026] (1) Preparation of pre-reaction solution: Dissolve 790 mg of functional monomer monohydroxygadolinium porphyrin and 6.5 μL of template molecule dimethyl methylphosphonate (DMMP) in 10 mL of chloroform, and then add 42.3 μL of cross-linking agent B Glycol dimethacrylate (EGDMA) and 25 mg initiator azobisisobutyronitrile (AIBN). Nitrogen gas was passed through the reaction mixture for 10 minutes, followed by ultrasonic degassing for 10 minutes. The polyvinylidene fluoride microporous filter membrane (PVDF membrane) was immersed in the above mixture, and put into the refrigerator to stand overnight.

[0027] (2) Membrane production: Take out the polyvinylidene fluoride microporous filter membrane in the mixed solution the next day and place it between two glass slides, irradiate with a 365nm ultraviolet lamp to initiate polymerization, turn over every 20 minutes, and irradiate for 12 hours Finally, the glass slides are separated to obtain a molecularly imprinted composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com