Macro film and fiber consisting of nanocapsules and nanotubes and preparation method thereof

A technology of nanocapsules and carbon nanotubes, which can be used in radiation absorbing coatings, ion implantation plating, coatings, etc., can solve the problem that the density cannot meet the requirements of wave absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

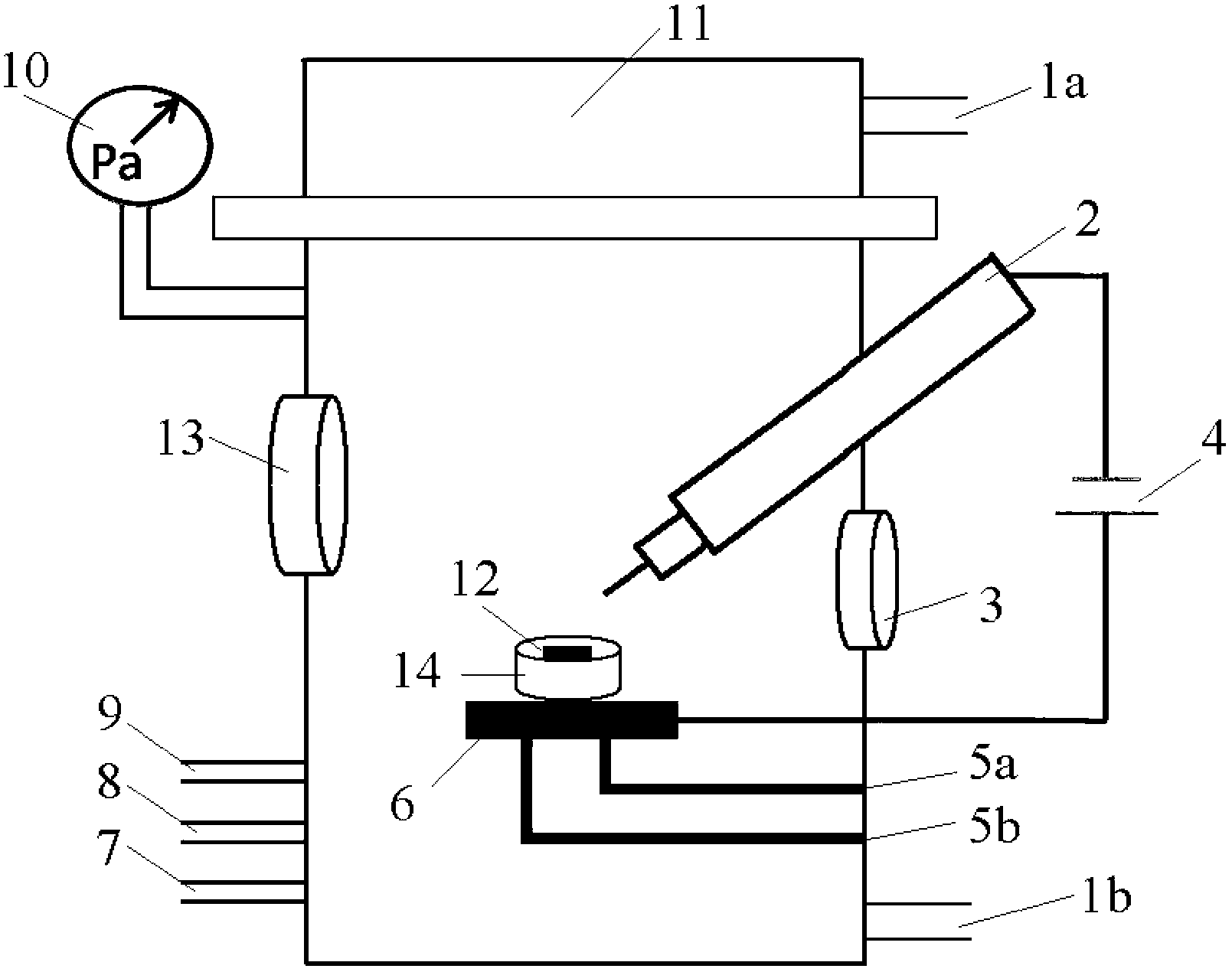

[0038] Preparation of particle films and composite fibers by plasma arc discharge technology:

[0039] Will figure 1 The upper cover 11 of the shown device is opened, the cathode 2 used is a graphite electrode with a purity of 98%, and the consumption anode target 12 used is 10 × 10 × 10 cm 3For the iron metal block, the distance between the cathode 2 and the anode target 12 is 3 cm. Between the water-cooled copper stage 6 and the anode target 12 is a graphite crucible 14 . Cover the upper cover 11 of the device, pass cooling water, and evacuate the entire working chamber through the vacuum evacuation window 3 connected to the evacuation system, then pass argon gas and hydrogen gas through the argon gas inlet 7 and the hydrogen gas inlet 8 respectively. (Ar: 0.2Mpa, H 2 : 0.1Mpa), inject 10ml of anhydrous ethanol through the carbon supply material inlet 9 (the partial pressure of ethanol entering the cavity is 0.2Mpa), turn on the DC pulsating power supply 4, the voltage is...

Embodiment 2

[0043] Will figure 1 The upper cover 11 of the shown device is opened, the cathode 2 used is a graphite electrode with a purity of 98%, and the consumption anode target 12 used is 15×15×15cm 3 For the iron metal block, the distance between the cathode 2 and the anode target 12 is 5 mm. Between the water-cooled copper stage 6 and the anode target 12 is a graphite crucible 14 . Cover the upper cover 11 of the device, pass cooling water, and evacuate the entire working chamber through the vacuum evacuation window 3 connected to the evacuation system, then pass argon gas and hydrogen gas through the argon gas inlet 7 and the hydrogen gas inlet 8 respectively. (Ar: 0.4Mpa, H 2 : 0.2Mpa), inject 15ml of absolute ethanol through the carbon supply material inlet 9 (the partial pressure of ethanol entering the cavity is 0.28Mpa), turn on the DC pulsating power supply 4, the voltage is 10-30V, the anode target material 12 and the cathode 2 During the arc discharge, the arc discharge ...

Embodiment 3

[0045] Will figure 1 The upper cover 11 of the shown device is opened, the cathode 2 used is a graphite electrode with a purity of 98%, and the consumption anode target 12 used is 12×10×15cm 3 For the iron metal block, the distance between the cathode 2 and the anode target 12 is 8 mm. Between the water-cooled copper stage 6 and the anode target 12 is a graphite crucible 14 . Cover the upper cover 11 of the device, pass cooling water, and evacuate the entire working chamber through the vacuum evacuation window 3 connected to the evacuation system, then pass argon gas and hydrogen gas through the argon gas inlet 7 and the hydrogen gas inlet 8 respectively. (Ar: 0.5Mpa, H 2 : 0.3Mpa), inject 20ml of absolute ethanol through the carbon supply material inlet 9 (the partial pressure of ethanol entering the cavity is 0.38Mpa), turn on the DC pulsating power supply 4, the voltage is 15-40V, the anode target material 12 and the cathode 2 During the arc discharge, the arc discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com