Anti-aging plastic pipe or anti-aging plastic pipe connector

A plastic pipe, anti-aging technology, applied in the direction of pipes/pipe joints/fittings, pipeline protection, pipeline damage/wear prevention, etc., can solve the problems of high investment and production costs, troublesome assembly and disassembly, and low production efficiency , to achieve the effect of improving service life, facilitating construction and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

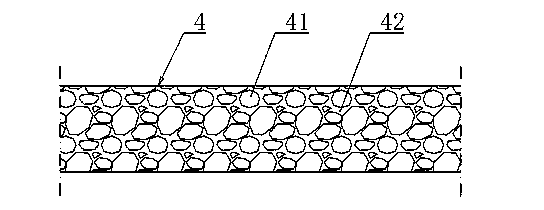

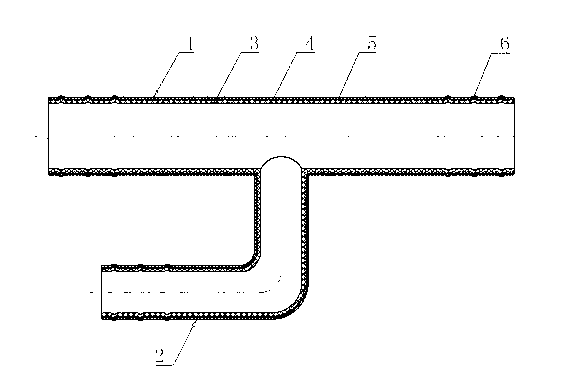

[0020] see figure 1 , an embodiment of an anti-aging plastic pipe joint of the present invention (a three-way structure, but not limited to a three-way structure), which is composed of a main channel part 1 and a branch channel part 2 of an integrated structure. The layer structure of the main channel part 1 and the branch channel part 2 of the plastic pipe joint is the same, and the inner side is the main body 3 of the pipe body, which is made of plastic, preferably black PE. A layer of anti-ultraviolet layer 4 mixed with glass powder is compounded on the outside of the tube body 3 .

[0021] A protective layer 5 can also be compounded on the outside of the ultraviolet protection layer 4 .

[0022] In this embodiment, the outer peripheral surfaces of the pipe joints of the main passage part 1 and the branch passage part 2 are provided with several rings of ribs 6 for firm connection with plastic pipes.

[0023] The composition and parts by weight of the anti-ultraviolet lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com