Two-dimensional silicon substrate photonic crystal line-defect slow optical waveguide device

A technology of photonic crystals and waveguide devices, applied in light guides, optics, optical components, etc., can solve problems that have not been reported in the past, and achieve the effects of good signal fidelity, high efficiency, and high group refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

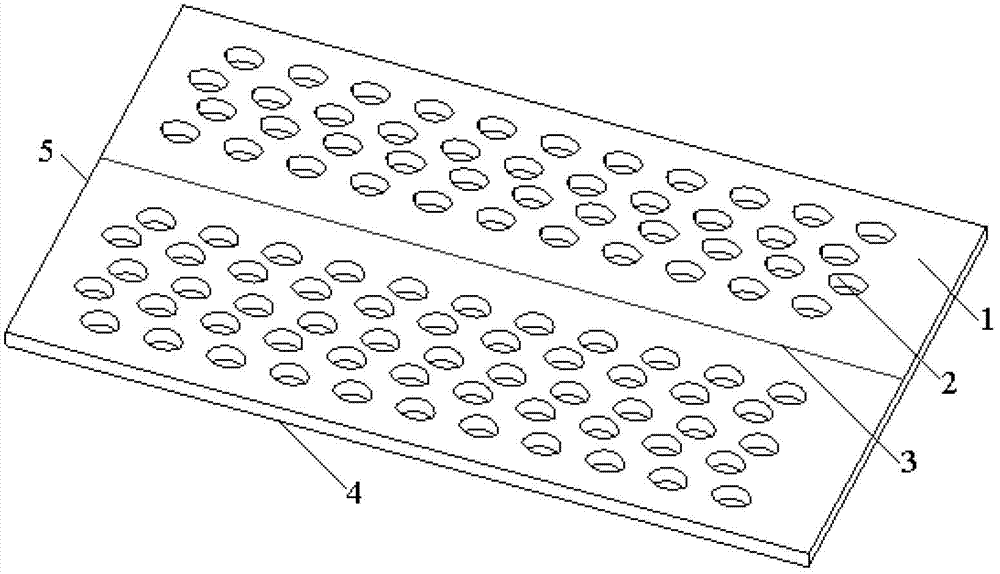

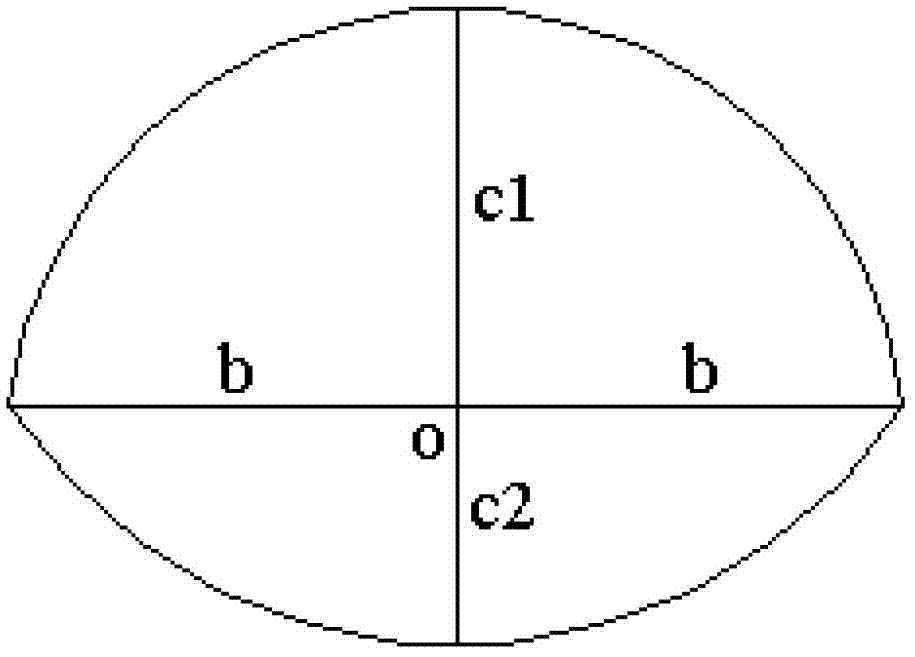

[0019] The main structure of this implementation includes a two-dimensional silicon wafer 1, a uniaxially symmetrical circular segment scattering element 2, a line defect 3, a long side 4 of the silicon wafer, and a short side 5 of the silicon wafer; Along the direction of the long side 4 of the two-dimensional silicon wafer 1, there are 6-10 rows of uniaxially symmetrical circular bow-shaped scattering elements 2 with the centerline of the two-dimensional silicon wafer as the axis of symmetry, and the symmetrical axis of the two-dimensional silicon wafer 1 There is a row of line defects 3 formed by unetched circular segment scattering elements; 90-100 uniaxially symmetrical circular segment scattering elements 2 are equally spaced on each row of uniaxially symmetrical circular segment scattering elements 2; The center of the uniaxially symmetrical circular segment scattering element 2 is arranged in an equilateral hexagon on the surface of the two-dimensional silicon wafer 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com