Package support of lighting device and surface processing method thereof

A technology for encapsulating brackets and light-emitting devices, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems affecting the long-term performance of light-emitting chip reliability, increase product defect rate, peeling, etc., to improve reliability and reliability, The effect of improving bonding strength and maintaining luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

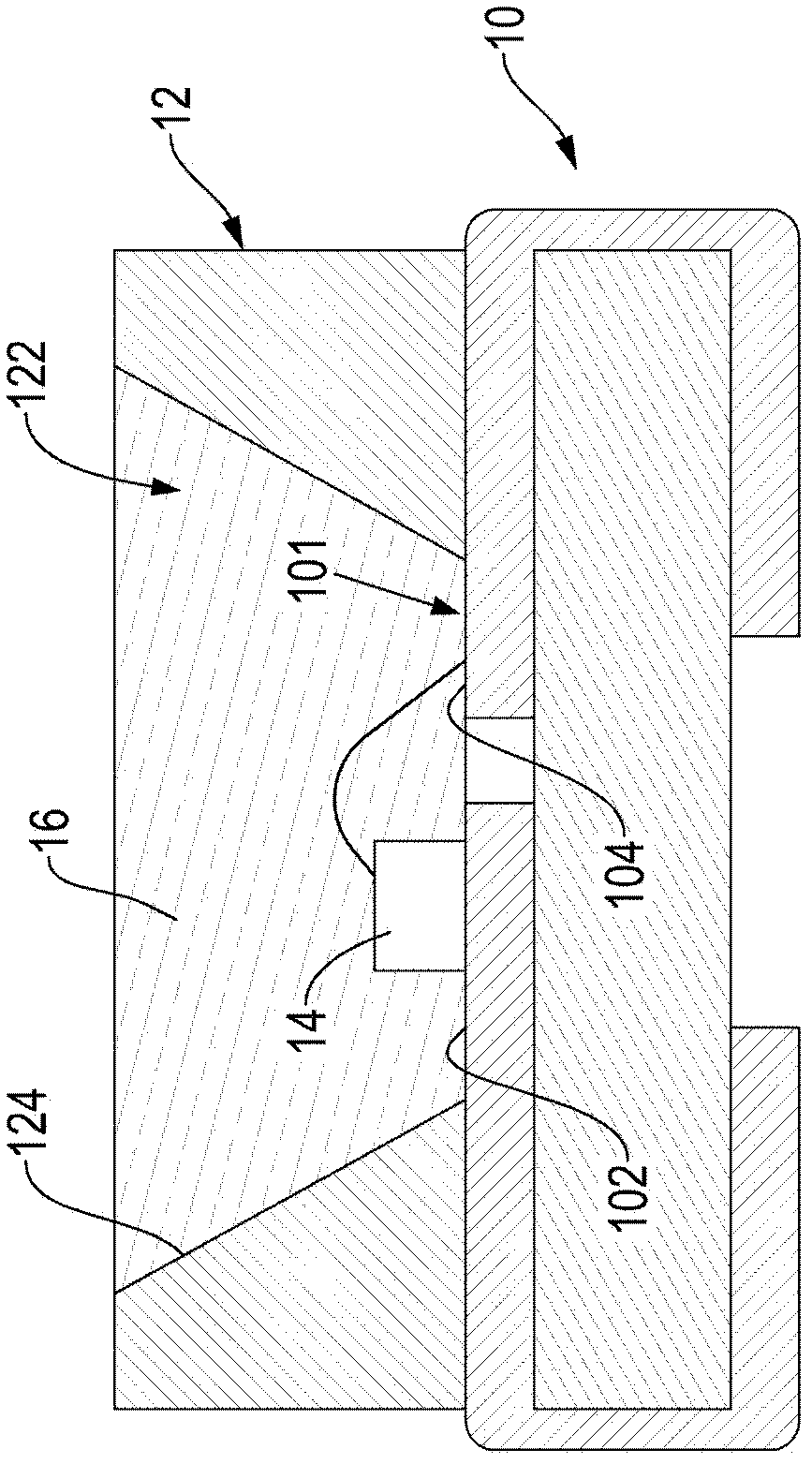

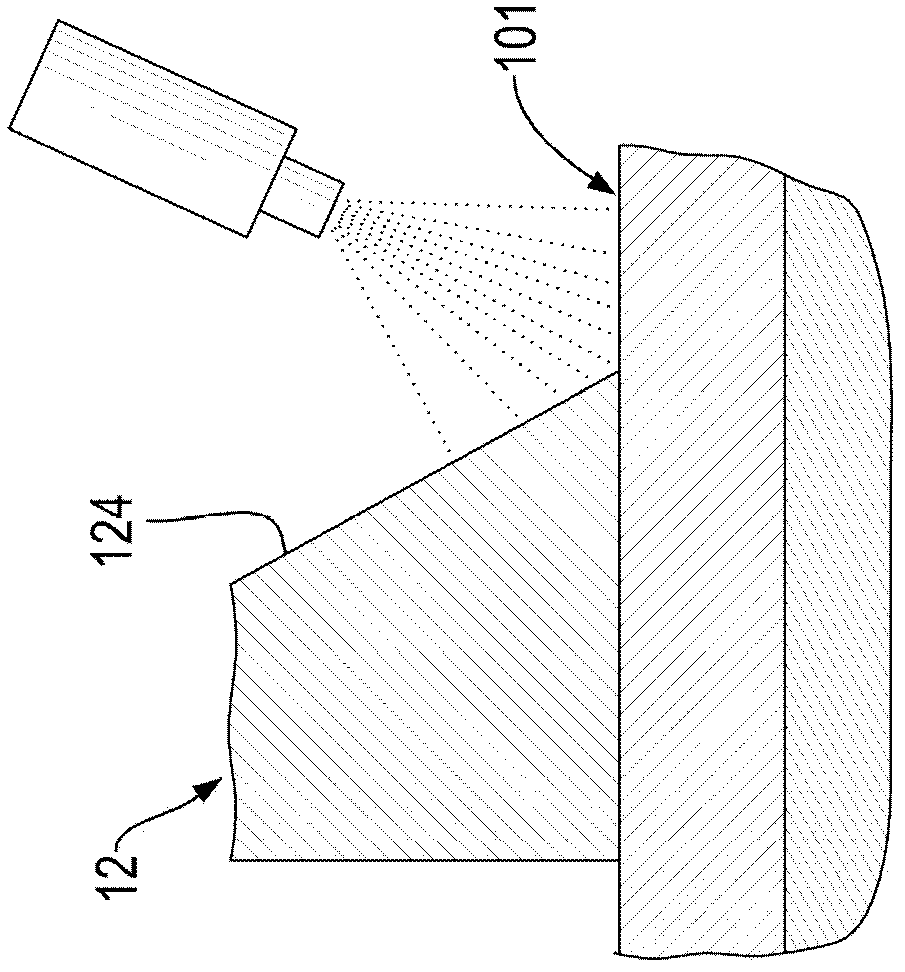

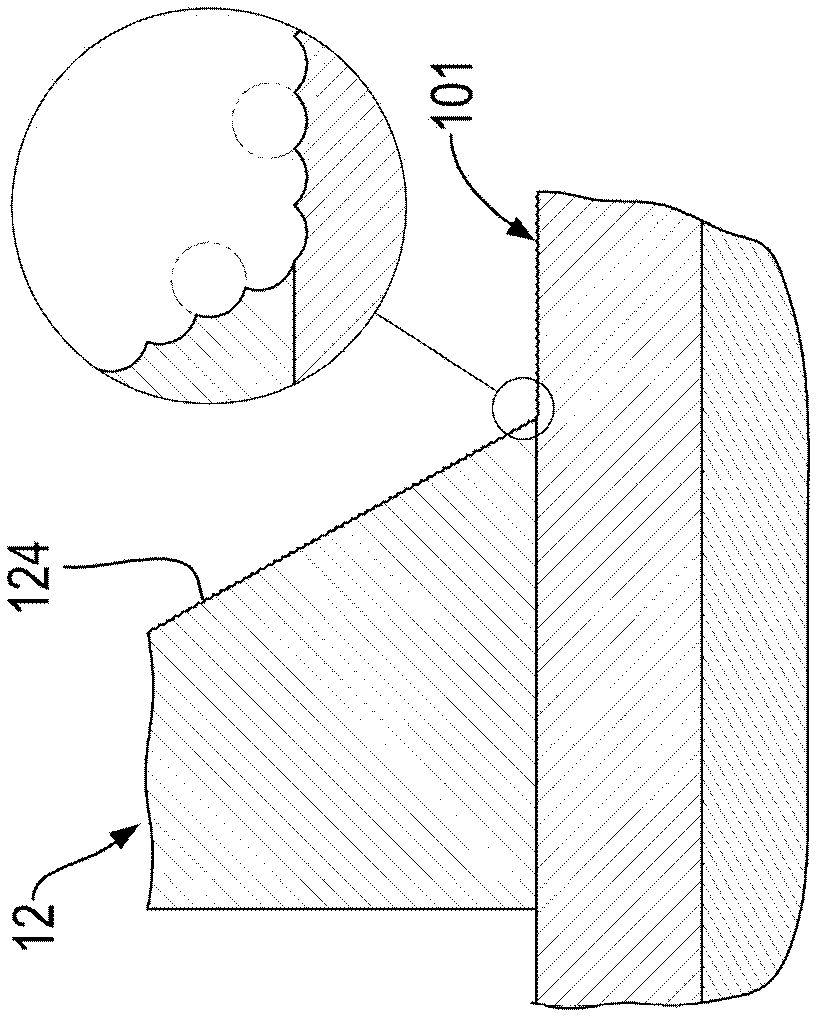

[0029] The present invention mainly provides a light-emitting device packaging bracket and its surface treatment method, please refer to figure 1 , it can be seen from the figure that the package holder structure of the present invention mainly includes a metal holder 10 and an optical cup body 12 . The metal bracket 10 can be made of copper alloy, iron alloy or aluminum alloy, preferably copper alloy. The surface of the metal bracket 10 is electroplated to form an electroplated surface, wherein the electroplating treatment can be copper-silver (Cu-Ag), nickel-silver (Ni-Ag), nickel palladium gold (NiPdAu), nickel tin (Ni-Sn), copper (Cu), nickel phosphorus (Ni-P), tin lead (Sn-Pb), nickel gold (Ni-Au), Nickel palladium gold (Ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com