High-stability hollow fibrous membrane and preparation method thereof

A high-stability, fiber-membrane technology, applied in the field of composite materials, can solve problems such as poor stability, low retention rate, and poor tensile strength, and achieve the effects of improved stability, simple process, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A high-stability hollow fiber membrane includes polyvinylidene fluoride membrane filaments, and cross-linked products are evenly embedded in the interior of the polyvinylidene fluoride membrane filaments and the apertures. The cross-linked product is formed by cross-linking polyvinyl alcohol and glutaraldehyde.

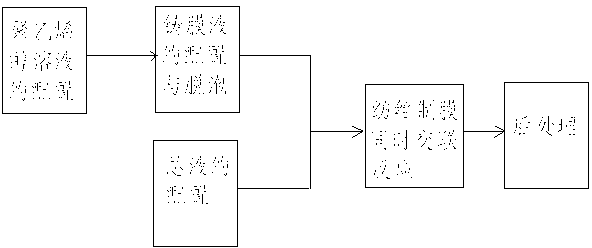

[0023] A kind of preparation method of hollow fiber membrane of high stability, such as figure 1 The shown technological process comprises the following steps:

[0024] 1) Polyvinyl alcohol and water are configured into a polyvinyl alcohol aqueous solution with a concentration of 15% by mass;

[0025] 2) Take 30g of polyvinyl alcohol aqueous solution and add it to 500ml of dimethylacetamide, keep the temperature at 65°C, stir evenly, then add 150g of polyvinylidene fluoride powder, continue to keep the temperature at 65°C and stir evenly;

[0026] 3) Add 20g of pore forming agent PVP and 10g of surfactant Tween 80 to the mixed solution obtained in step 2), st...

Embodiment 2

[0035] A high-stability hollow fiber membrane includes polyvinylidene fluoride membrane filaments, and cross-linked products are evenly embedded in the interior of the polyvinylidene fluoride membrane filaments and the apertures. The cross-linked product is formed by cross-linking polyvinyl alcohol and glutaraldehyde.

[0036] A kind of preparation method of hollow fiber membrane of high stability, such as figure 1 The shown technological process comprises the following steps:

[0037] 1) Polyvinyl alcohol and water are configured into an aqueous solution of polyvinyl alcohol with a concentration of 18% by mass;

[0038] 2) Take 40g of polyvinyl alcohol aqueous solution and add it to 500ml of dimethylacetamide, keep the temperature at 75°C, stir evenly, then add 160g of polyvinylidene fluoride powder, continue to keep the temperature at 75°C and stir evenly;

[0039] 3) Add 40g of pore-forming agent PVP and 20g of surfactant Tween 80 to the mixed solution obtained in step 2)...

Embodiment 3

[0047] A high-stability hollow fiber membrane includes polyvinylidene fluoride membrane filaments, and cross-linked products are evenly embedded in the interior of the polyvinylidene fluoride membrane filaments and the apertures. The cross-linked product is formed by cross-linking polyvinyl alcohol and glutaraldehyde.

[0048] A kind of preparation method of hollow fiber membrane of high stability, such as figure 1 The shown technological process comprises the following steps:

[0049] 1) Polyvinyl alcohol and water are configured into a polyvinyl alcohol aqueous solution with a concentration of 14% by mass;

[0050] 2) Take 35g of polyvinyl alcohol aqueous solution and add it to 500ml of dimethylacetamide, keep the temperature at 85°C, stir evenly, then add 170g of polyvinylidene fluoride powder, continue to keep the temperature at 85°C and stir evenly;

[0051] 3) Add 30g of pore-forming agent PVP and 15g of surfactant Tween 80 to the mixed solution obtained in step 2), st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com