Acrylic acid Guerbet alcohol ester and preparation method and application thereof

A technology of Guerbet alcohol and acrylic acid, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of low applicability and high cost, achieve shortened reaction time, cheap price, and benefit The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

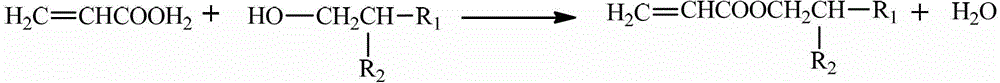

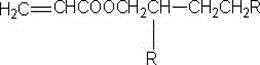

Method used

Image

Examples

Embodiment 1

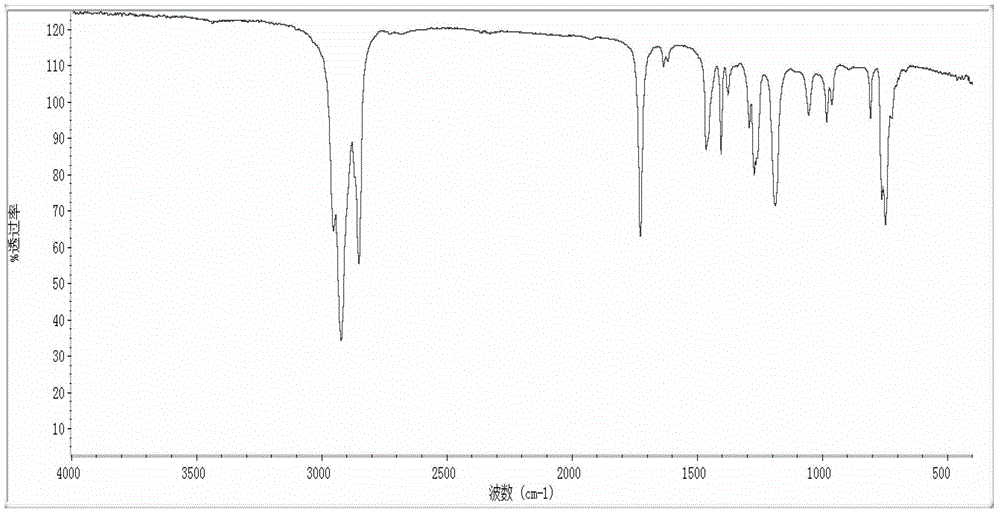

[0022] The preparation of acrylic acid 2-butyl octanol: take respectively acrylic acid and 2-butyl octanol that the molar ratio is 1.2:1, 2-butyl octanol, hydroquinone, SO 4 2- / M x o y Add the type solid superacid catalyst and solvent toluene into the three-necked flask, stir well, and raise the temperature to 110°C. Wherein the consumption of hydroquinone is 0.6% of the total weight of acid and alcohol, SO 4 2- / M x o y The consumption of type solid superacid catalyst is 1.0% of the total weight of acid and alcohol, and the consumption of solvent toluene is 30% of the total weight of acid and alcohol. Put acrylic acid into a constant pressure separatory funnel, add it dropwise into a three-necked flask, stir well, and the reaction time is 3 hours. After the reaction was over, the solvent toluene was evaporated by rotary evaporation, filtered under reduced pressure, and then washed with 10% NaOH solution and saturated Na 2 SO 4 Solution 500ml washes the filtrate succ...

Embodiment 2

[0024] The preparation of 2-pentyl nonanol acrylate: take respectively acrylic acid and 2-pentyl nonanol with a molar ratio of 1.2:1, 2-pentyl nonanol, hydroquinone, p-toluenesulfonic acid catalyst and solvent Add benzene into the three-necked flask, stir well, and raise the temperature to 120°C. Wherein the consumption of hydroquinone is 0.8% of the total weight of acid and alcohol, the consumption of p-toluenesulfonic acid catalyst is 1.2% of the total weight of acid and alcohol, and the consumption of solvent benzene is 40% of the total weight of acid and alcohol. Put acrylic acid into a constant pressure separatory funnel, add it dropwise into a three-necked flask, stir well, and the reaction time is 3.5h. After the reaction was over, the solvent benzene was evaporated, and then 10% NaOH solution and saturated Na 2 SO 4 500ml of the solution was washed successively. Take the oily viscous liquid in the upper layer, put it into a vacuum drying oven, and dry it for 12 hour...

Embodiment 3

[0026] The preparation of 2-hexyldecyl acrylate: take respectively acrylic acid and 2-hexyldecyl alcohol in a mol ratio of 1.3:1, add 2-hexyldecyl alcohol, hydroquinone, p-toluenesulfonic acid catalyst and solvent benzene into three Neck flask, stir well, and raise the temperature to 125°C. Wherein the consumption of hydroquinone is 1.2% of the total weight of acid and alcohol, the consumption of p-toluenesulfonic acid catalyst is 2.0% of the total weight of acid and alcohol, and the consumption of solvent benzene is 40% of the total weight of acid and alcohol. Put acrylic acid into a constant pressure separatory funnel, add it dropwise into a three-necked flask, stir well, and the reaction time is 3 hours. After the reaction was over, the solvent benzene was evaporated, and then 10% NaOH solution and saturated Na 2 SO 4 500ml of the solution was washed successively. Take the oily viscous liquid in the upper layer, put it into a vacuum drying oven, and dry it for 12 hours t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com