Method for preparing polysulfonamide/nanometer TiO2 composition fiber by electrostatic spinning method

A nano-titanium dioxide, electrospinning technology, applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve problems such as poor anti-ultraviolet performance, improve poor anti-ultraviolet performance, simple preparation device, and acceptable preparation process. Strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of polysulfoneamide / nano-titanium dioxide composite spinning solution:

[0025] Nano-titanium dioxide (nano-TiO 2 ) into a drying oven for drying to remove moisture. Use a measuring cylinder to measure 1mL of N,N’-dimethylacetamide (DMAC) solvent into a beaker, and weigh 0.061g of dried nano-TiO with a balance 2 , pour it into a beaker and stir it with a glass rod to make it preliminarily mix with the DMAC solvent, then seal the beaker with plastic wrap and put it into an ultrasonic cleaner for 0.5 hours of ultrasonic vibration to prepare a mixed solution (when ultrasonic oscillation, ensure that the ultrasonic The water level in the cleaner is higher than the DMAC liquid level mark in the beaker); pour 50g of nano-TiO into the mixed solution that has been initially ultrasonically oscillated 2 It is 12wt% PSA spinning stock solution, and stir it with a magnetic heating stirrer for 0.5 hours, seal it with plastic wrap after completion, put it in an ultr...

Embodiment 2

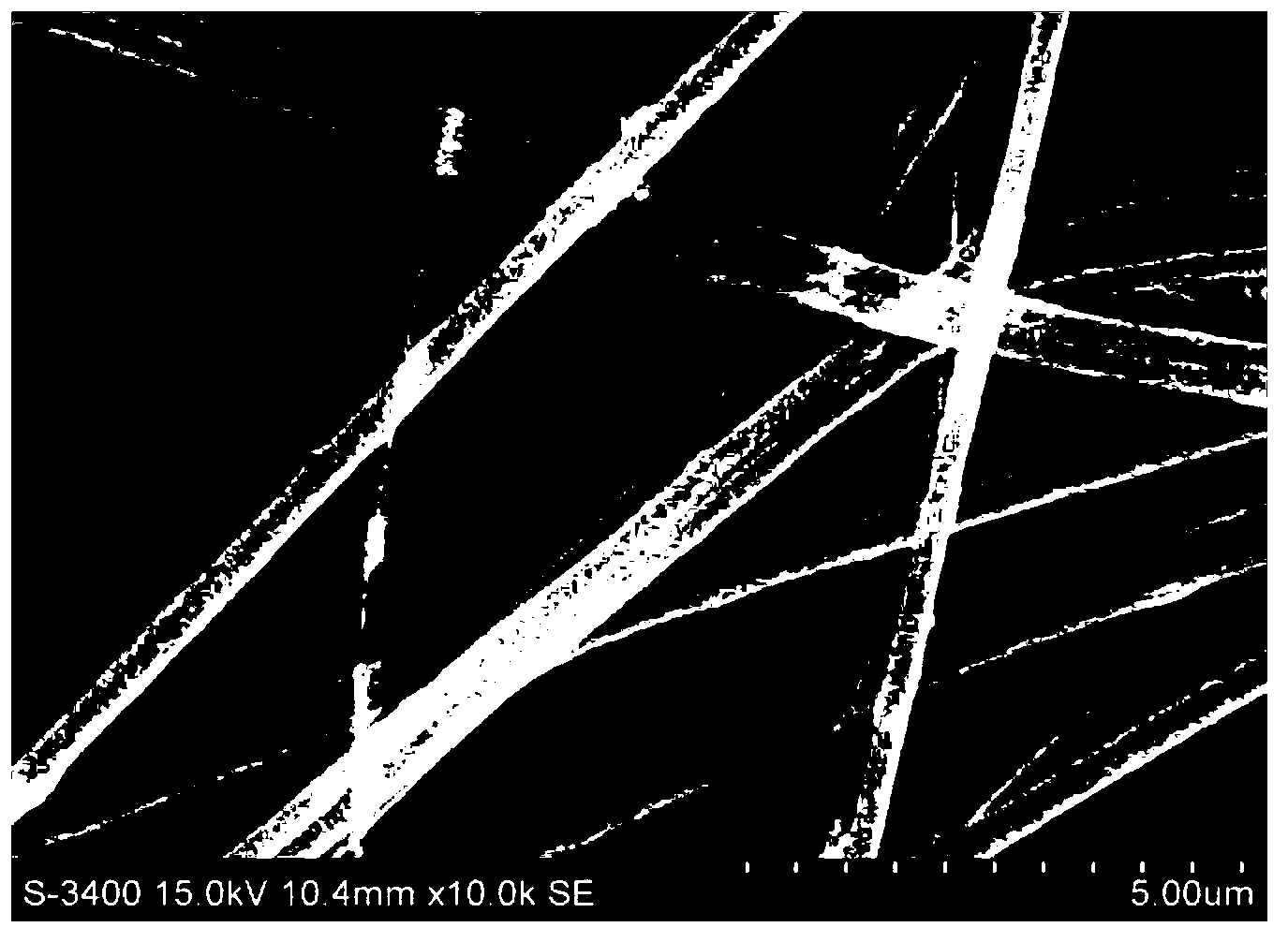

[0029] The nano-TiO in the step (1) in the embodiment 1 2 The addition amount is adjusted to 0.186g, the addition amount of DMAC is adjusted to 3mL, and other conditions remain unchanged, the nano-TiO 2 It is 3wt% polysulfone amide / nano-titanium dioxide composite fiber. figure 1 It is a scanning electron microscope picture of the nanocomposite fiber prepared in this example. It can be seen from the figure that nano-titanium dioxide particles are embedded on the surface of the fiber.

Embodiment 3

[0031] The nano-TiO in the step (1) in the embodiment 1 2 The addition amount of DMAC is adjusted to 0.316g, the addition amount of DMAC is adjusted to 5mL, and other conditions remain unchanged, the nano-TiO 2 It is 5wt% polysulfone amide / nano-titanium dioxide composite fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com