Simple mask-cleaning method

A mask and simple technology, applied in the field of cleaning, can solve the problems of long time period, dirty, dirty mask, etc., and achieve the effect of saving cost, ensuring accuracy, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

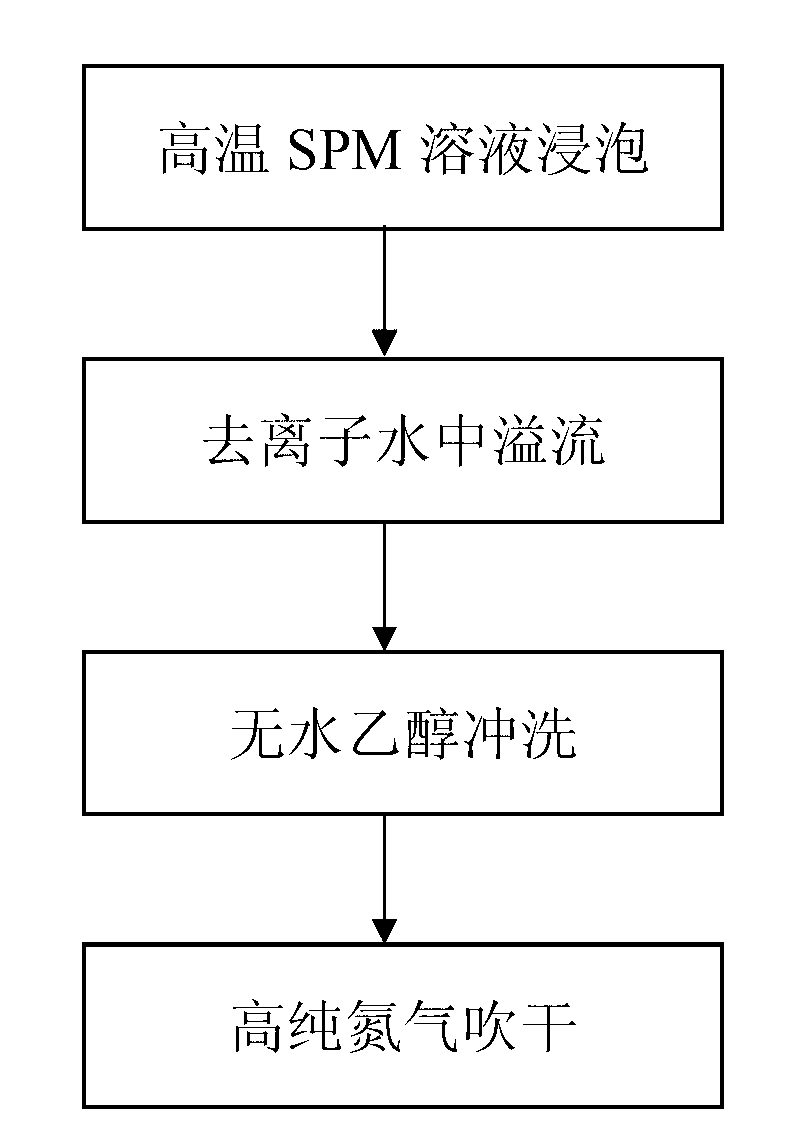

[0024] The concentration of concentrated sulfuric acid used in this example is 98%, the concentration of hydrogen peroxide is 31%, the SPM mixture is composed of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 3:1, the SPM container is a quartz tank, the temperature is 70°C, and the high-purity nitrogen gas is 5N, dust-free cloth is electronic grade, deionized water is square resistance 18MΩ / □, mask plate holder is made of PP material, the cleaning flow chart is as follows figure 1 shown. In order to test the cleaning effect, the products after the photolithography of the mask plate were detected before cleaning to obtain figure 2 the results shown, figure 2 Medium and large areas of red marks are caused by dirty masks. The main process of cleaning is as follows: put the material rack containing the mask plate in the SPM mixture at a temperature of 70°C for 5 minutes, then take it out and place it in deionized water to overflow for 3 times, and then...

example 2

[0026] The machine and method used in the test in this example are the same as in Example 1, except that the temperature of the SPM in this example is increased to 120° C., and the soaking time is increased to 20 minutes. The implementation process of this example draws on the results of Example 1, raising the temperature of SPM to 120°C to make the foaming of hydrogen peroxide more intense, and the soaking time is correspondingly increased to increase the contact time of the mask in the SPM solution. After the mask plate was cleaned, the test method in Example 1 was still used to detect the pattern transfer of the product after photolithography. It was found that the dirt on the mask plate had been cleaned. There was no fixed red mark in the test result in Figure 4, which satisfied the process. Production requirements, so far the cleaning has reached the expected goal, and the mask plate can be put into production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com