Method for selectively reducing specific nitrosamines in cigarette smoke

A cigarette smoke and selectivity technology, which is applied in the fields of tobacco, smoke oil filter elements, food science, etc., can solve the problem of selective reduction of N-nitrosamines, etc., and achieve the effect of convenient operation and simple addition method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

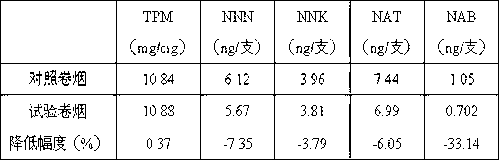

[0025] Dissolve 1g of chitosan in 50mL of 1% acetic acid solution, add 50mL of methanol, and stir to obtain a chitosan solution; dissolve 6g of β-cyclodextrin in 100mL of 0.5M hydrochloric acid solution, add dropwise 10mL of glutaraldehyde with a concentration of 25% was stirred and reacted for 2 hours at 85°C to obtain a cyclodextrin-glutaraldehyde polymer solution; the cyclodextrin-glutaraldehyde solution was added dropwise to the chitosan solution, Stir the reaction for 1 hour at 85°C, adjust the pH value to 8 with 1M sodium hydroxide solution, continue stirring for 10 minutes, filter, wash the filter residue with water, and dry at 40°C to obtain brown-yellow solid particles , is a chitosan-cyclodextrin-glutaraldehyde polymer. Pass through a 40-mesh sieve, weigh it quantitatively, add it to the filter tip at a level of 9mg / cigarette, make a test cigarette, and do a comparative test with the control cigarette. Except that the control cigarettes do not contain additives, oth...

Embodiment 2

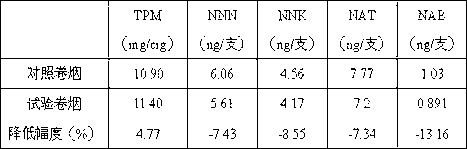

[0030]Dissolve 1g of chitosan in 50mL of 1% acetic acid solution, add 50mL of methanol, and stir to obtain a chitosan solution; dissolve 3g of β-cyclodextrin in 50mL of 0.5M hydrochloric acid solution, add dropwise 7 mL of glutaraldehyde with a concentration of 25% was stirred and reacted for 2 hours at 85°C to obtain a cyclodextrin-glutaraldehyde polymer solution; the cyclodextrin-glutaraldehyde solution was added dropwise to the chitosan solution, Stir the reaction at 85°C for 1 hour, adjust the pH value to 8 with 1M sodium hydroxide solution, continue stirring for 10 minutes, filter, wash the filter residue with ethanol, and dry at 40°C to obtain a brown-yellow solid The particles are chitosan-cyclodextrin-glutaraldehyde polymers. Pass through a 40-mesh sieve, weigh it quantitatively, add it to the filter tip at a level of 10 mg / cigarette, make a test cigarette, and do a comparative test with the control cigarette. Except that the control cigarettes do not contain additive...

Embodiment 3

[0035] The chitosan-cyclodextrin-glutaraldehyde polymer prepared in Example 1 was added to the filter tip at a level of 8mg / cigarette to make a test cigarette, which was compared with the control cigarette. Except that the control cigarettes do not contain additives, other cigarette materials such as auxiliary materials, sizes, filter rods, etc. are exactly the same as the test cigarettes. The filter stick is a cellulose acetate filter stick.

[0036] According to the method of the above examples, the results show that the wet tar in cigarette smoke is reduced by 4.43%, while the reductions of NNN, NNK, NAT and NAB are 16.26%, 34.54%, 9.89% and 8.21%, respectively. The reduction range of nitramine is still greater than the reduction range of tar, reaching the purpose of selective harm reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com