Preparation method for controllable duplex metal alloy nano particle

A technology of alloy nanoparticles and bimetal, which is applied in the field of preparation of Pt/Pd-M bimetal alloy nanoparticles, can solve problems such as difficulty in obtaining alloy nanoparticles, and achieve uniform and controllable size and simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

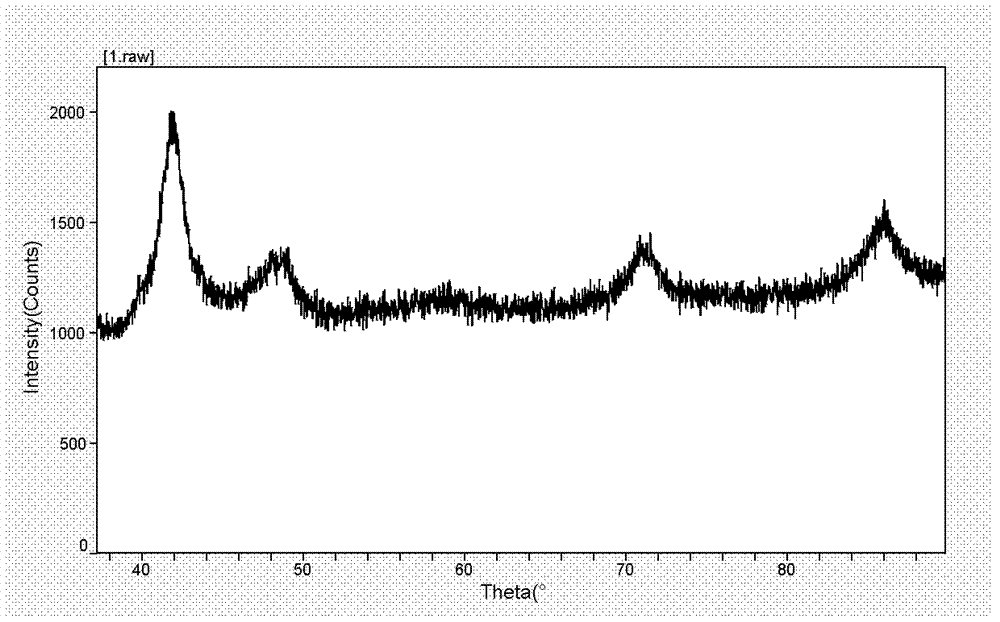

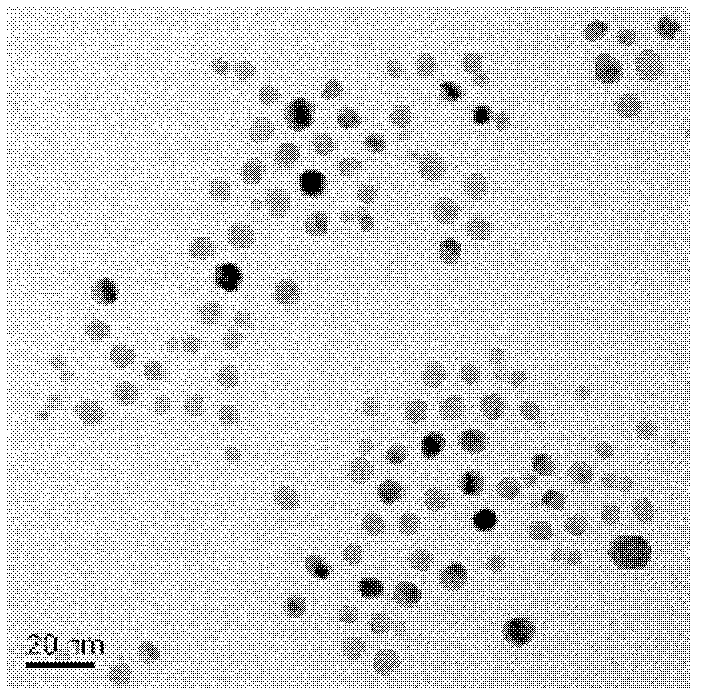

Embodiment 1

[0028] Put 20ml of octadecene in a 50ml three-necked flask, fill it with nitrogen, heat the above solvent to 75°C under magnetic stirring and nitrogen protection, and inject 2ml of n-butyllithium n-hexane with a concentration of 2.2mol / L into the above solvent Solution, after about two minutes, 0.065mmolH dissolved in protective agent A (4ml oleylamine) 2 PtCl 6 ·6H 2 O(chloroplatinic acid hexahydrate) and 0.065mmolCo(CH 3 COO) 2 (Cobalt acetate) solution is injected into the above-mentioned solvent, and the solution in the three-necked flask turns brown-black instantly, and is kept at this temperature for 30 minutes, then heated up to 260°C and kept for 2 hours, and then begins to cool down, and when it drops to about 120°C, Inject 1.5ml of protective agent B (tri-n-octylphosphine) into the reaction product and wait for it to cool down to room temperature. Move the reaction product into a 50ml centrifuge tube, take 5ml and put it into another centrifuge tube, add about 40...

Embodiment 2

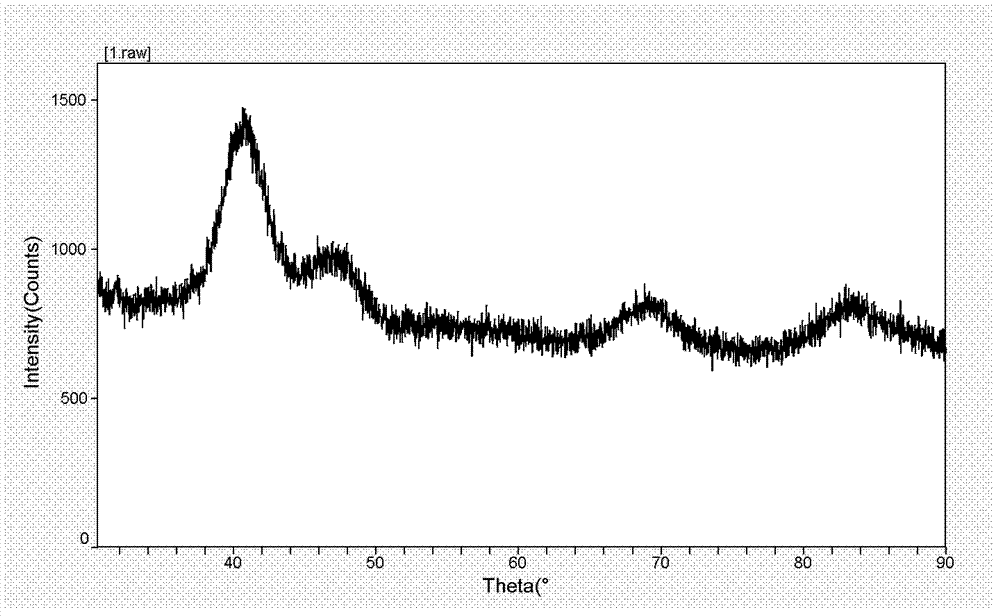

[0032] Put 20ml of octadecene in a 50ml three-necked flask, fill it with nitrogen, heat the above solvent to 75°C under magnetic stirring and nitrogen protection, and inject 2ml of n-butyllithium n-hexane with a concentration of 2.2mol / L into the above solvent Solution, after about two minutes, 0.065mmolH dissolved in protective agent A (4ml oleylamine) 2 PtCl 6 6H2O (chloroplatinic acid hexahydrate) and 0.065mmol Fe(acac) 3 The (iron acetylacetonate) solution is injected into the above solvent, and the solution in the three-necked flask instantly turns brown-black, and is kept at this temperature for 30 minutes. Inject 1.5ml of protective agent B (tri-n-octylphosphine) into the reaction product and wait for it to cool down to room temperature. Move the reaction product into a 50ml centrifuge tube, take 5ml and put it into another centrifuge tube, add about 40ml of ethanol and centrifuge at 8000 rpm, disperse the centrifuged precipitate with 2ml of toluene each time, and the...

Embodiment 3

[0036] Put 20ml of octadecene in a 50ml three-necked flask, fill it with nitrogen, heat the above solvent to 75°C under magnetic stirring and nitrogen protection, and inject 1ml of n-butyllithium n-hexane with a concentration of 2.2mol / L into the above solvent Solution, after about two minutes, 0.13mmolH dissolved in protective agent A (2ml oleylamine) 2 PtCl 6 ·6H 2 O(chloroplatinic acid hexahydrate) and 0.13mmol Ni(acac) 2 (Nickel acetylacetonate) solution is injected into the above solvent, and the solution in the three-necked flask turns brown-black instantly, and is kept at this temperature for 30 minutes, then heated up to 260°C and kept for 2 hours, and then begins to cool down, and when it drops to about 120°C Inject 1.5ml of protective agent B (tri-n-octylphosphine) into the reaction product and wait for it to cool down to room temperature. Move the reaction product into a 50ml centrifuge tube, take 5ml and put it into another centrifuge tube, add about 40ml of eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com