Method for recycling uranium in uranium-contained waste water

A recovery method and waste water technology, applied in the field of uranium recovery in uranium-containing waste water, to achieve the effects of increasing uranium concentration, high efficiency, and overcoming interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

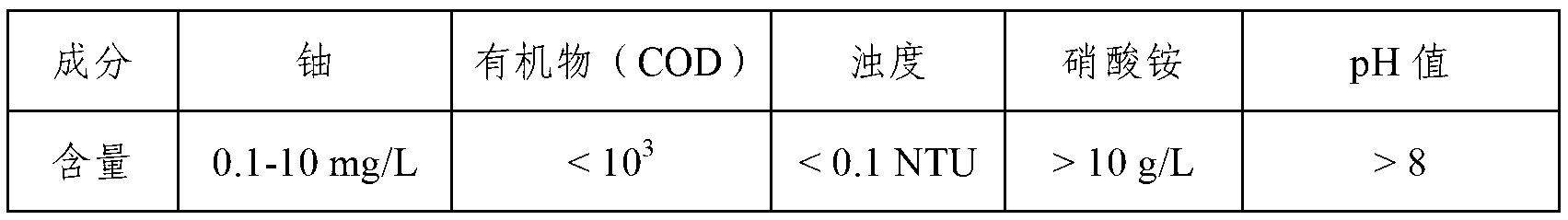

[0036] During the production of a certain batch of fuel elements, 25 liters of process wastewater needs to be treated. Table 2 shows the content of the main components in this batch of wastewater.

[0037] Table 2 Contents of main components of process wastewater in a certain batch of fuel element production process

[0038]

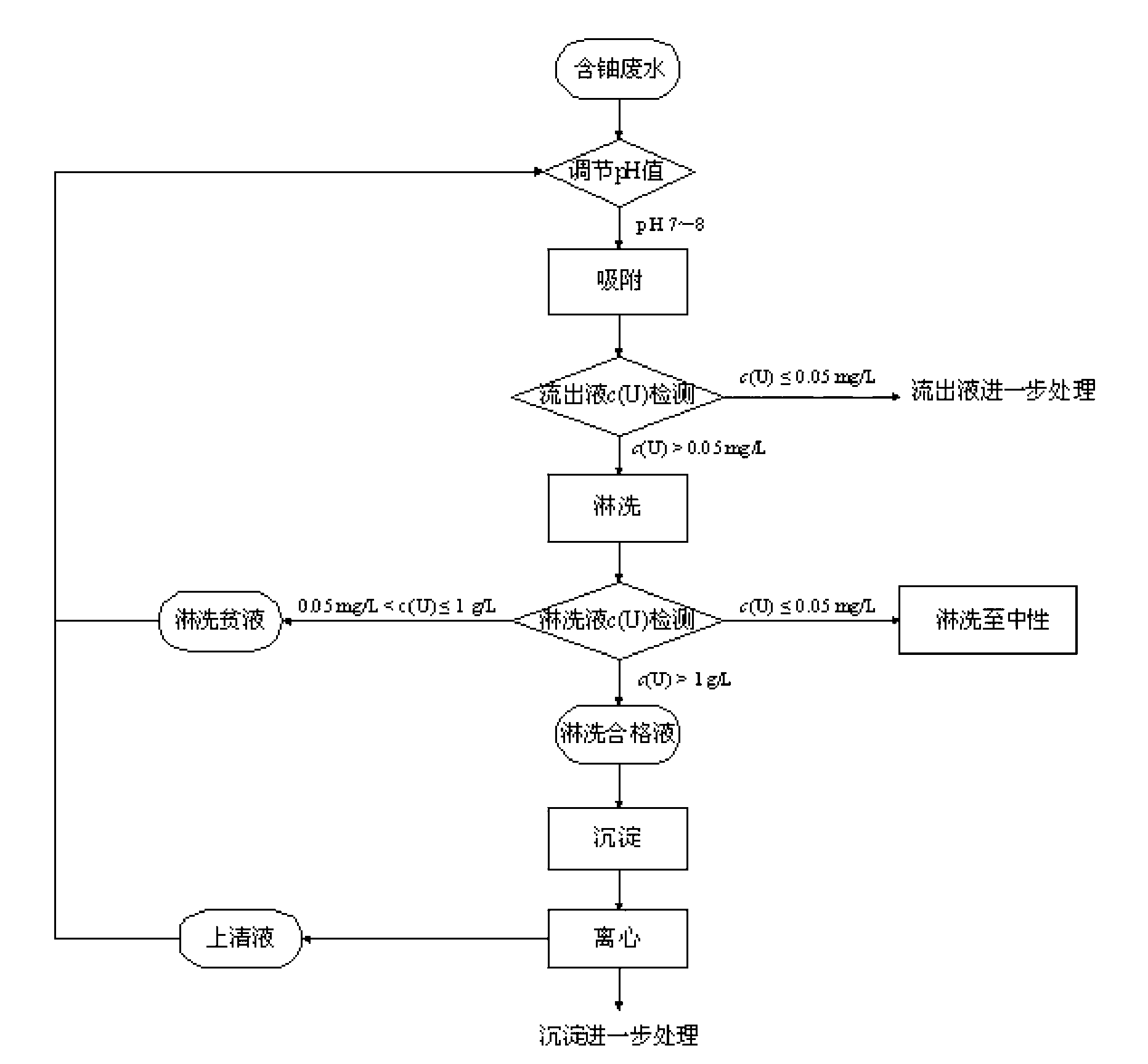

[0039] In order to realize the recovery and enrichment of trace amounts of uranium in the waste water, the pre-treatment of the waste water is carried out first, the ammonia is removed by distillation, and then the solid impurities and high-molecular organic matter in the waste water are removed by filtration, so that the uranium-containing waste water is used as the waste water to be treated in the present invention. For uranium-containing wastewater, the enrichment of uranium is realized through the silica gel adsorption-leaching process. For the specific process, see figure 1 shown.

[0040] The pretreatment process is carried out according to the...

Embodiment 2

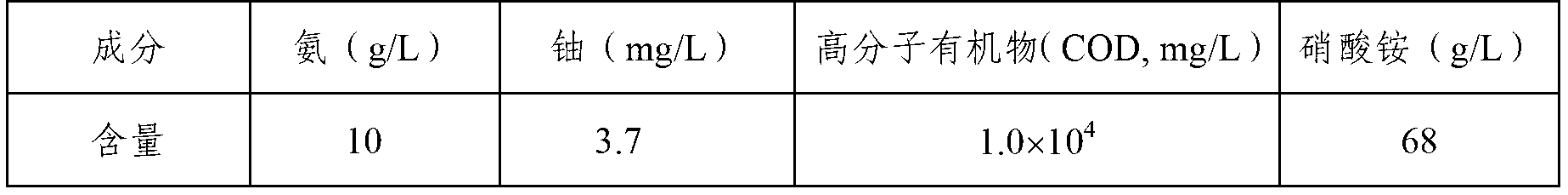

[0052] During the production of a certain batch of fuel elements, 500 liters of process wastewater needs to be treated. Table 5 shows the content of the main components in this batch of wastewater.

[0053] Table 5 Contents of main components of process wastewater in a certain batch of fuel element production process

[0054]

[0055] In order to realize the recovery and enrichment of trace amounts of uranium in the waste water, the pre-treatment of the waste water is firstly carried out, the ammonia is removed by distillation, and then the solid impurities and high-molecular organic matter in the waste water are removed by filtration, so that the uranium-containing waste water is used as the waste water to be treated in the present invention. For uranium-containing wastewater, the enrichment of uranium is achieved through silica gel adsorption-leaching process.

[0056] The pretreatment process is carried out according to the following scheme: first, the waste water is hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com