Synthesis and application of resin for copper-clad plate

A resin for copper clad laminates, technology of copper clad laminates, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of poor resin storage and operability, hard copper clad laminates, low thermal stress, etc. , to achieve the effect of low cost, easy operation and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

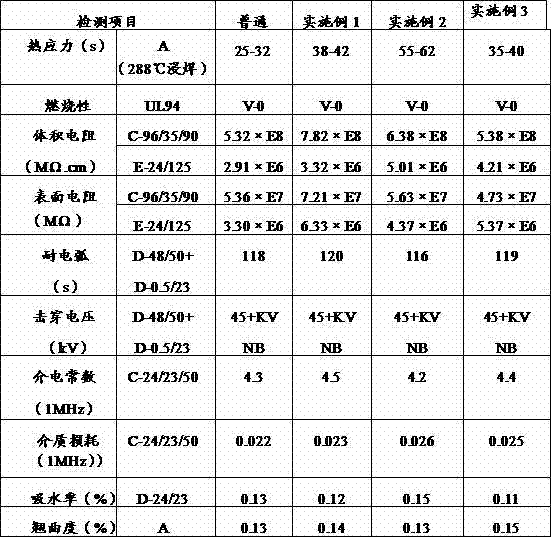

[0010] Synthesis of a resin for copper clad laminates: first mix 100 parts by mass of phenol, 60 parts of formaldehyde and 25 parts of paraformaldehyde, then add 4 parts of triethylamine as a catalyst, stir evenly, and heat to 80 React at -85°C for 100 minutes, and finally add 40 parts of methanol as a solvent, and mix to form a resin with a solid content of 55%. Its application is: use the resin as a primary glue, immerse it into the wood pulp paper of the core material substrate of CEM-1 copper clad laminate, so that the resin content is controlled at 13%, that is, Example 1; 7%, that is, Example 2; 20% , i.e. embodiment 3; then soak the secondary glue, the secondary glue of 3 embodiments is different: the secondary glue of embodiment 1: molecular weight is the epoxy resin and powder mixing system of 800-2000, solid content is 70% The secondary glue of embodiment 2: molecular weight is the epoxy resin of 800-2000 and powder mixing system, solid content is 69%; The secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com