Wear-resistant steel plate and manufacture method thereof

A wear-resistant steel plate and a manufacturing method technology, applied in the field of wear-resistant steel, can solve the problems of poor machinability and poor machinability, achieve excellent machinability, excellent wear resistance, and reduce the content of carbon and alloying elements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

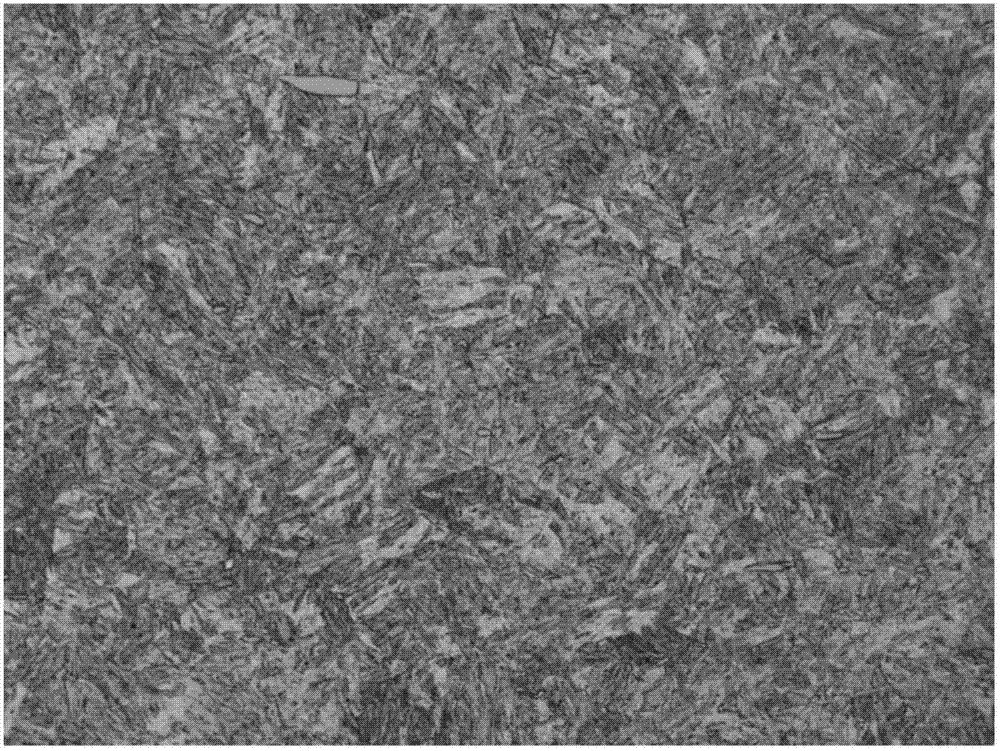

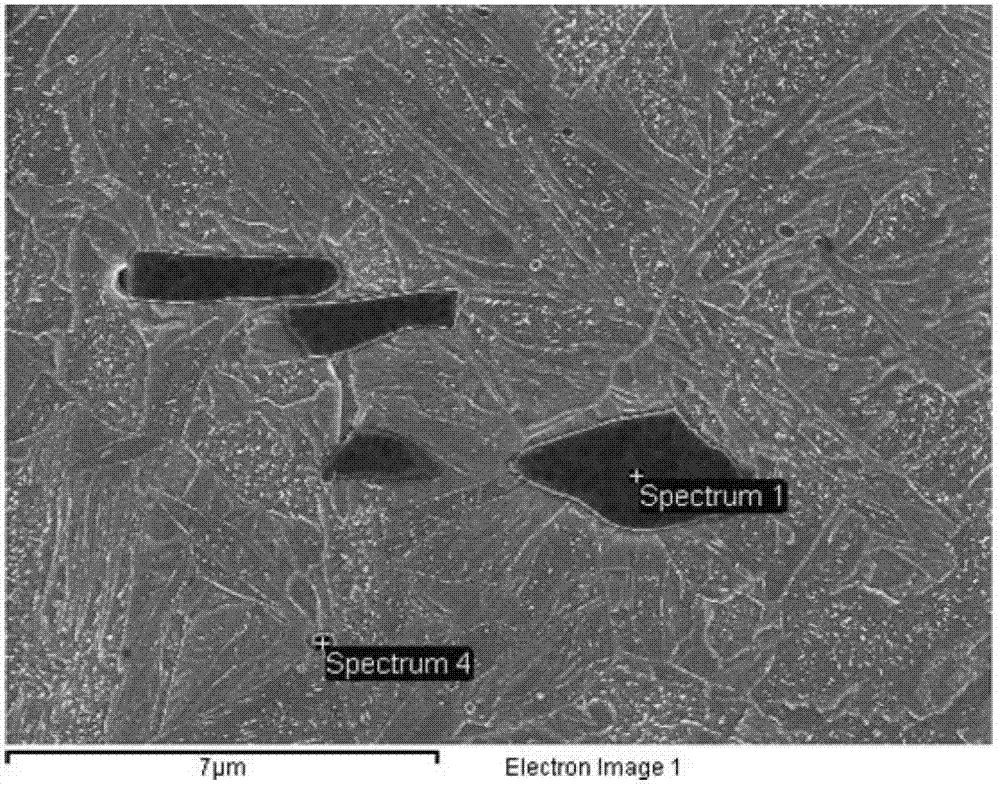

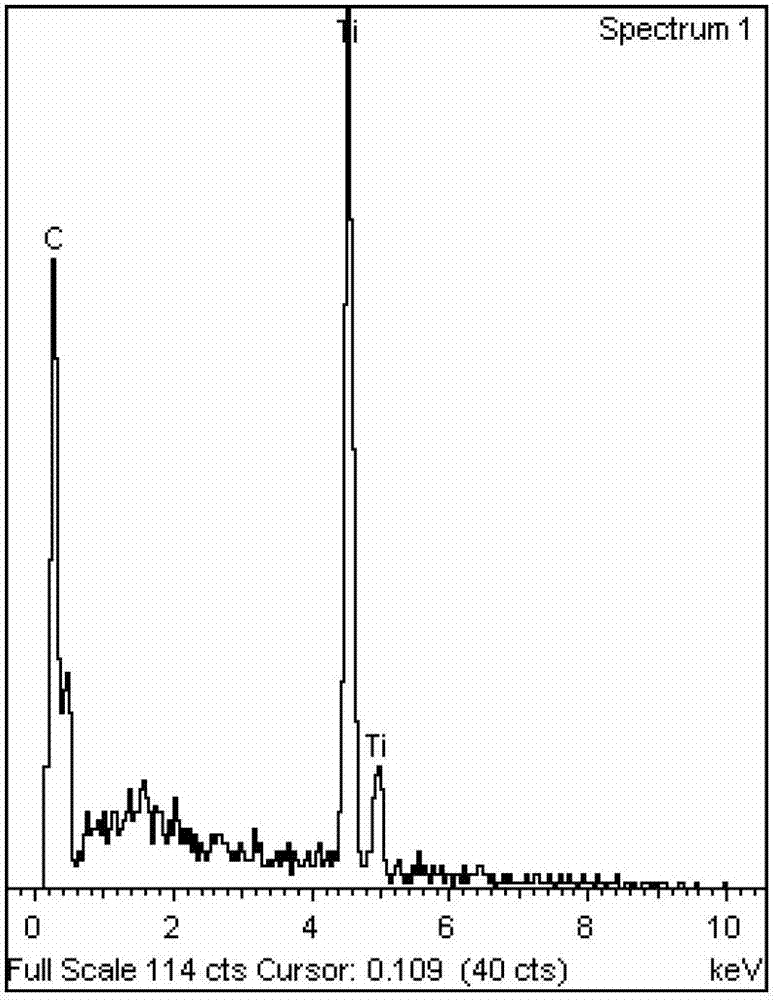

[0043] The wear-resistant steel plates of the following examples 1-10 and the steel plates of comparative example 1, the weight percentages of their chemical components are as shown in table 1; the wear-resistant steel plates of embodiments 1-10 and the steel plates of comparative example 1 (comparative example 1 It is the embodiment in the Chinese patent CN1865481A) and the manufacturing method is: smelting the corresponding smelting raw materials, then casting→heating→rolling→cooling directly after rolling→tempering (tempering is not required), control each embodiment and comparative example 1 The mass percentage distribution of chemical elements in the steel plate, wherein, in the heating step, the slab heating temperature is 1000-1250°C, and the temperature is kept for 1-3 hours; in the rolling step, the rough rolling temperature is 950-1200°C, and the finish rolling The temperature is 790-880°C; in the cooling step, use water cooling to cool below 400°C and then air cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com