Flowing high temperature and high pressure phase equilibrium measuring device and application method thereof

A technology of high temperature and high pressure, measuring device, applied in sampling device, color/spectral characteristic measurement, etc., to achieve the effect of accurate and reliable measurement process, accurate and reliable data, and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

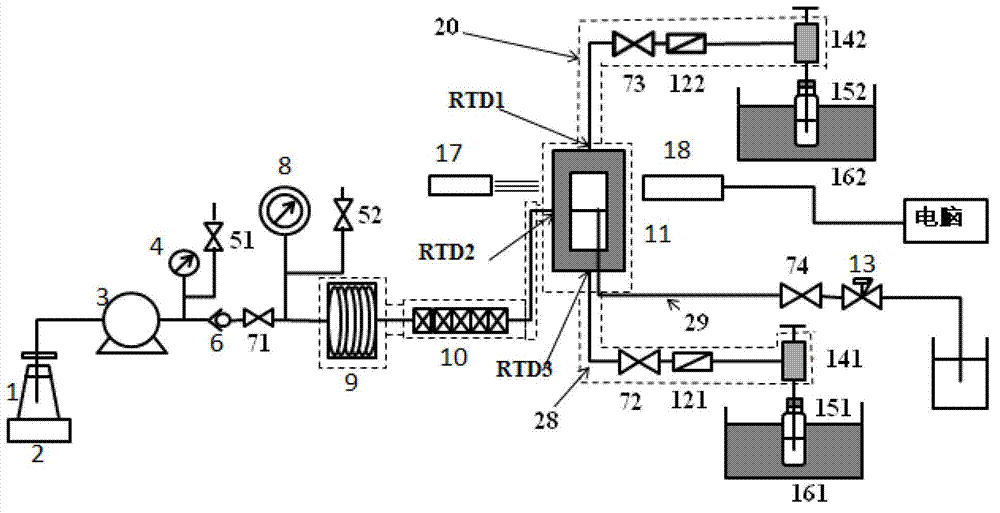

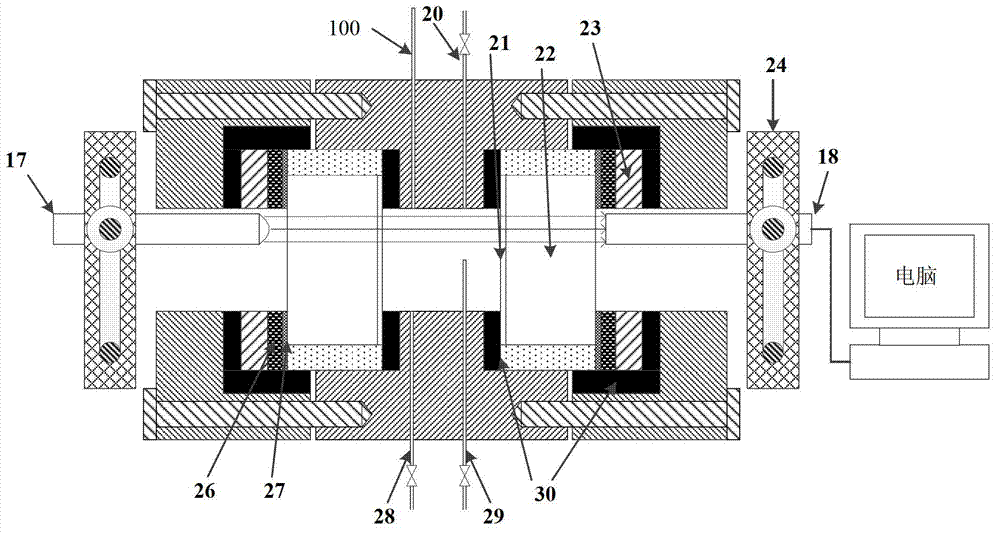

Method used

Image

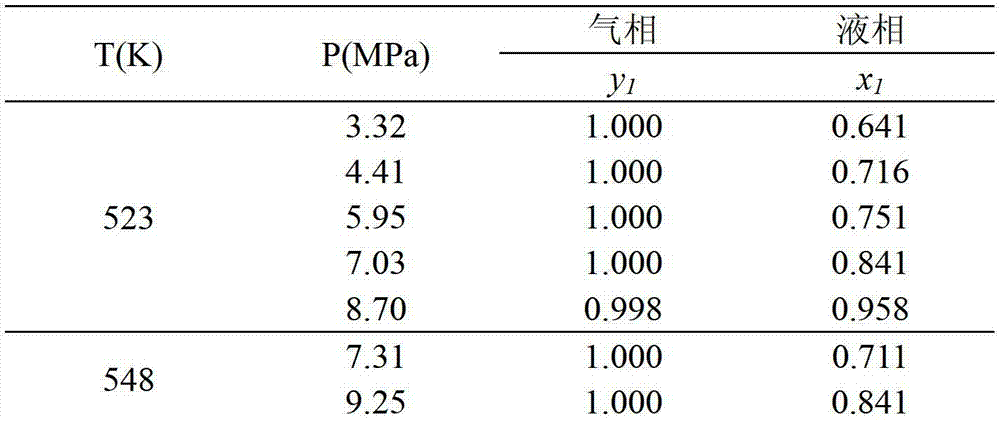

Examples

Embodiment 1

[0042] (1) Heat the preheating coil 9 and tubular mixer 10 of the mobile high-temperature and high-pressure phase equilibrium measurement device to 473-523K (lower than the equilibrium temperature 50K set in the experiment) by an electric heating system, and put the balance kettle 11, The gas phase sampling tube 20 and the liquid phase sampling tube 28 are heated to the equilibrium temperature (523-573K) set in the experiment, and methanol and α-tocopherol (the molar fraction of methanol is 0.96-0.98) are filled in the liquid reagent bottle 1 .

[0043] (2) Extract the mixture of methanol and α-tocopherol with feed pump 3 at a feed rate of 7.49-9.34 mL per minute. The preheating coil 9 is preheated to 50-100K lower than the equilibrium temperature, and after being fully mixed in the tube mixer 10, the pressurized liquid enters the equilibrium tank 11. After the solution stays in the balance kettle 11 for 3.79-4.18 minutes, it enters the liquid recovery container through the m...

Embodiment 2

[0050] (1) Use an electric heating system to preheat the preheating coil 9 and mixer 10 of the mobile high temperature and high pressure phase balance measurement device to 473-523K (about 50K lower than the equilibrium temperature set in the experiment), and put the balance kettle 11, The gas phase sampling tube 20 and the liquid phase sampling tube 28 are heated to the equilibrium temperature (523-573K) set in the experiment, and methanol and methyl oleate are filled in the liquid reagent bottle 1 (the molar fraction of methanol is 0.96-0.98) .

[0051] (2) Extract the mixture of methanol and methyl oleate with feed pump 3 at a feed rate of 7.49-9.34 mL per minute. The preheating coil 9 is preheated to 50-100°C lower than the equilibrium temperature, and after being fully mixed in the tube mixer 10, the pressurized liquid enters the equilibrium kettle 11. After the solution stays in the balance kettle 11 for 3.79-4.18 minutes, it enters the liquid recovery container through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com