Preparation method of solid phosphate ion electrode based on aluminum and aluminum phosphate

An aluminum phosphate and phosphate technology, which is applied in the field of preparation of solid phosphate electrodes, can solve the problems of large volume and difficult long-term monitoring, and achieves the effects of simple preparation method, good anti-interference and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

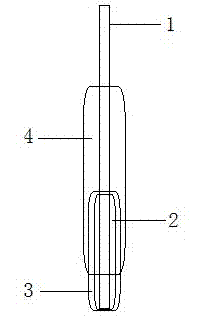

[0028] Based on aluminum, the preparation method steps of the solid phosphate root electrode of aluminum phosphate are as follows:

[0029] 1) Clean the aluminum wire 1 with a diameter of 0.5 to 1 mm and a length of 5 to 15 cm in acetone and dilute acid in order to remove surface oil and oxide film, then wash with deionized water and dry;

[0030] Other organic solvents, such as gasoline, can also be used to remove oil stains. There is a dense and hard oxide film on the metal surface, and the oxide film is dissolved after dilute acid treatment. When the aluminum wire bubbles in the dilute acid, it indicates that the oxide film has been dissolved, and it should be taken out of the dilute acid as soon as possible and enter the next process to prevent the surface from being re-oxidized.

[0031] 2) Dissolve phosphoric acid in 5 to 10 times alcohol to prepare a phosphoric acid solution;

[0032] Alcohol is used as a solvent for phosphoric acid because the intermediate product of...

Embodiment 1

[0050] 1) Clean the aluminum wire 1 with a diameter of 0.5 mm and a length of 10 cm in acetone and dilute acid in order to remove surface oil and oxide film, then wash with deionized water and dry;

[0051] 2) Dissolve phosphoric acid in 5 times alcohol to prepare phosphoric acid solution;

[0052] 3) Use the aluminum wire as the working electrode, the graphite as the reference electrode, and the Pt sheet as the auxiliary electrode, connect them to the electrochemical workstation, immerse the above three electrodes in the phosphoric acid solution, and use the cyclic scanning potential method with a scanning rate of 50mVs -1 , potential range 0 to 1V, scanning for 8 minutes, a white aluminum phosphate 2 precipitate is formed on the surface of the aluminum wire; after the electroplating is completed, it is first soaked in alcohol, and then dried at room temperature or vacuum dried;

[0053] 4) Dissolve the following reagents from Sigma in tetrahydrofuran (THF) 10 times the total...

Embodiment 2

[0060] 1) Clean the aluminum wire 1 with a diameter of 1 mm and a length of 10 cm in acetone and dilute acid in order to remove surface oil and oxide film, then wash with deionized water and dry;

[0061] 2) Dissolve phosphoric acid in 8 times alcohol to prepare phosphoric acid solution;

[0062] 3) Use the aluminum wire as the working electrode, the graphite as the reference electrode, and the Pt sheet as the auxiliary electrode, connect them to the electrochemical workstation, immerse the above three electrodes in the phosphoric acid solution, and use the cyclic scanning potential method with a scanning rate of 80mVs -1 , with a potential range of 0 to 1V, scanning for 5 minutes, a white aluminum phosphate 2 precipitate is formed on the surface of the aluminum wire; after the electroplating is completed, it is first soaked in alcohol, and then dried at room temperature or vacuum dried;

[0063] 4) Dissolve the following reagents from Sigma in N,N-dimethylformamide (DMF) 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com