Carbon dioxide adsorbent and application thereof

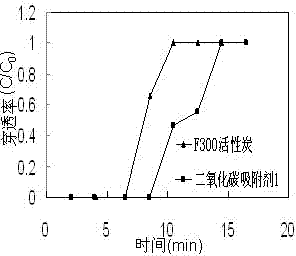

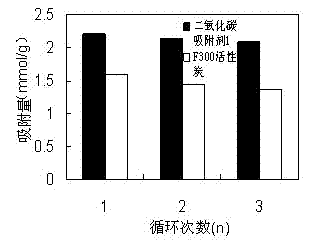

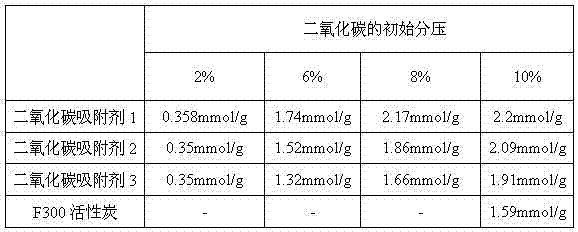

A carbon dioxide and adsorbent technology, which is applied in the field of carbon dioxide treatment in air pollution control, can solve the problems of limited adsorption capacity and low content of activated carbon surface groups, and achieve the effects of excellent regeneration performance, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Pretreatment of NaY molecular sieves: In a muffle furnace, NaY molecular sieves were calcined at 350° C. for 3.5 hours.

[0027] Add 40ml of absolute ethanol to a 200ml beaker, then add 20ml of aniline, stir and mix. Weigh 3 g of pretreated NaY molecular sieves and add them into the above mixture, stir for 2 h to mix well, and heat to 20°C. Add 58ml of ammonium persulfate aqueous solution preheated to 20°C with a concentration of 1M, carry out polymerization reaction for 20h under stirring, and keep the reaction temperature at 20°C to obtain solid particles. The solid particles were successively washed with distilled water and ethanol, and dried at 75°C.

[0028] Put the dried solid particles into a tube furnace, blow in nitrogen, and raise the temperature to 700°C at 5°C / min. The carbonization reaction time of solid particles at 700°C is 3h. The carbonization reaction product was repeatedly washed with 40% HF, then washed with a large amount of distilled water and e...

Embodiment 2

[0031] Pretreatment of HY-type molecular sieves: In a muffle furnace, HY-type molecular sieves were calcined at 200°C for 8 hours.

[0032] Add 40ml of absolute ethanol to a 200ml beaker, then add 15ml of aniline, stir and mix. Weigh 3g of pretreated HY type molecular sieve and add it into the above mixture, stir for 5h to mix, heat to 90°C and keep it warm. Add 58ml of ammonium persulfate aqueous solution (concentration: 1M) preheated to 90°C, and carry out polymerization reaction at 90°C for 10 hours while stirring to obtain solid particles. The solid particles were successively washed with distilled water and ethanol, and dried at 80°C.

[0033] Put the dried solid particles into a tube furnace, blow in nitrogen gas, and raise the temperature to 750°C at a rate of 2°C / min. The carbonization reaction time of solid particles at 750°C is 3h. The carbonization reaction product was repeatedly washed with 40% HF, then washed with a large amount of distilled water and ethanol u...

Embodiment 3

[0036] NH 4 Pretreatment of Y-type molecular sieve: In the muffle furnace, NH 4 Y-type molecular sieves were calcined at 600°C for 1h.

[0037] Add 40ml of absolute ethanol to a 200ml beaker, then add 35ml of aniline, stir and mix. Weigh 3 g of pretreated NH 4 Y-type molecular sieves were added to the above mixed solution, stirred for 3 hours, and then kept at a constant temperature at 40°C. Add 58ml of ammonium persulfate aqueous solution (concentration: 1M) preheated to 40°C, the polymerization reaction starts, react at 40°C with stirring for 15h, and obtain solid particles. The solid particles were successively washed with distilled water and ethanol, and dried at 75°C.

[0038] Put the dried solid particles into a tube furnace, blow in nitrogen, and raise the temperature to 800°C at a rate of 10°C / min. The carbonization reaction of solid particles at 800°C is 2h. The carbonization reaction product was repeatedly washed with 40% HF, then washed with a large amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com