Method for preparing temperature-sensitive graphene/polymer hybrid material

A hybrid material, graphene technology, applied in the field of materials, can solve the problems of graphene research and application difficulties, weak interaction, insoluble in water, etc., to achieve the effects of easy control, improved solubility, and broadened development and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

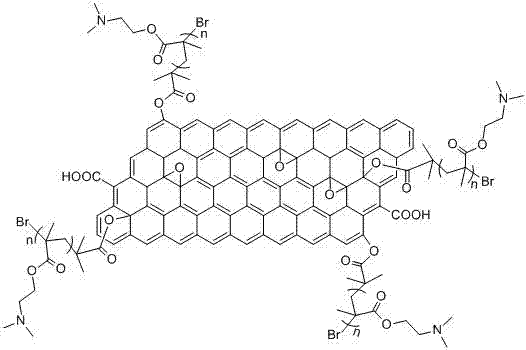

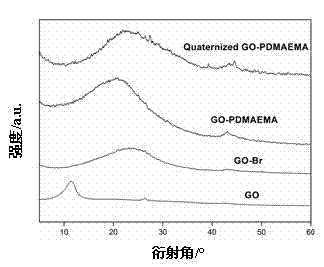

[0024] Mix 1g of graphene oxide and 30ml of N-N-dimethylformamide in a flask evenly, add 30ml of dibromoisobutyryl bromide and 20ml of triethylamine into the flask containing the mixture, and react in an ice bath After 24 hours, wash with a large amount of chloroform and distilled water after filtering, and dry in a vacuum oven to obtain dried brominated graphene oxide.

[0025] Take 0.1g of brominated graphene oxide, dissolve it in a flask with 5ml of N-N-dimethylformamide equipped with a magnet, and then add 4g of methacrylic acid-N, N-dimethylformamide to the flask in turn Ethyl ester, 15mg of cuprous bromide, 70μL of bipyridine, the system was reacted at 60°C for 24 hours under the protection of nitrogen, the product was diluted with tetrahydrofuran and centrifuged with a centrifuge, repeated centrifugation, and placed in a vacuum oven After drying, the hybrid material of graphene oxide / poly(N,N-dimethylethyl methacrylate) was obtained.

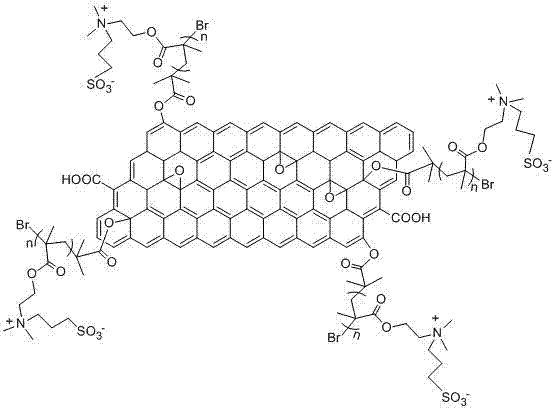

[0026] Take 40mg of graphene oxid...

Embodiment 2

[0030] Mix 1g of graphene oxide and 25ml of N,N-dimethylacetamide in a flask, add 25ml of dibromoisobutyryl bromide and 15ml of triethylamine into the flask containing the mixture, and place in an ice bath React in 20 hours, wash with a large amount of chloroform and distilled water after filtering, put into vacuum oven after drying, obtain the brominated graphene oxide of drying.

[0031] Take 0.1g of brominated graphene oxide and dissolve it in a flask containing 4ml of N, N-dimethylacetamide equipped with a magnet, and then add 6g of methacrylic acid-N, N-dimethacrylate to the flask in turn. Methyl ethyl ester, 25 mg of cuprous bromide, 90 μL of hexamethyltriethylenetetramine, the system was reacted at 80 °C for 30 hours under the protection of nitrogen, and the product was diluted with tetrahydrofuran and then centrifuged in a centrifuge. Repeated centrifugation and drying in a vacuum oven to obtain a graphene oxide / poly(N,N-dimethylethyl methacrylate) hybrid material.

...

Embodiment 3

[0034] Mix 1g of graphene oxide and 40ml of N,N-diethylformamide in a flask, add 40ml of dibromoisobutyryl bromide and 25ml of triethylamine into the flask containing the mixture, and place in an ice bath Reacted in medium for 30 hours, washed with a large amount of chloroform and distilled water after filtration, and dried in a vacuum oven to obtain dry brominated graphene oxide.

[0035] Take 0.15g of brominated graphene oxide, dissolve it in a flask with 8ml of N-N-diethylformamide equipped with a magnet, and then add 5g of methacrylic acid-N, N-dimethyl Ethyl ester, 15 mg of cuprous chloride, 70 μL of bipyridine, the system was reacted at 70 ° C for 20 hours under the protection of nitrogen, the product was diluted with tetrahydrofuran and then centrifuged with a centrifuge, and the centrifugation was repeated several times to remove the catalyst and untreated Impurities such as monomers of the reactant are centrifuged and dried in a vacuum oven to obtain a hybrid material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com