Method for producing gamma-aminobutyric acid by using banana biological enzyme method

A technology of aminobutyric acid and bio-enzyme method, which is applied in the field of producing γ-aminobutyric acid by banana bio-enzyme method, can solve complex processing problems, and achieve the effects of simple production process, specific reaction and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

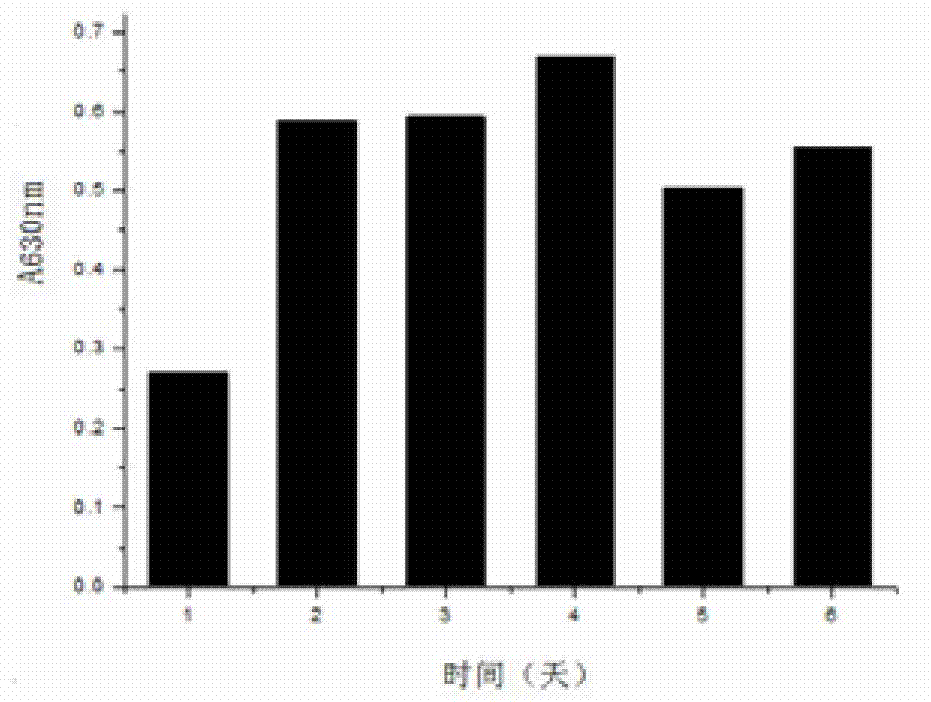

Embodiment 1

[0031] (1) Prepare the extraction solution: 0.05mol / L Na 2 HPO 4 / NaH 2 PO 4 , 0.15mol / L NaCl, 0.2mmol / L vitamin B 6 Or pyridoxal phosphate PLP, 30mg / L CaCl 2 , pH 5.7;

[0032] (2) Chop and grind the ripe whole banana (with belt and pulp), add 2L of extraction solution to each 1kg of banana, stir well, and stand at room temperature for extraction for 4 hours;

[0033] (3) After centrifugation at 7000rpm for 10 minutes, the supernatant is glutamic acid decarboxylase solution;

[0034] (4) Add 15g of glutamic acid or sodium glutamate to the glutamic acid decarboxylase solution, control the pH value at 4.5-5.5, stir at 150r / min for 2-3 hours at 37°C, and then add 3-3 5g of glutamic acid or sodium glutamate, the pH value is controlled at 5.0-5.5, and this is repeated until the enzyme activity disappears. Here, the enzyme activity is measured using the Berthelot reaction principle;

[0035] (5) After the reaction is completed, add 1% (w / v) ...

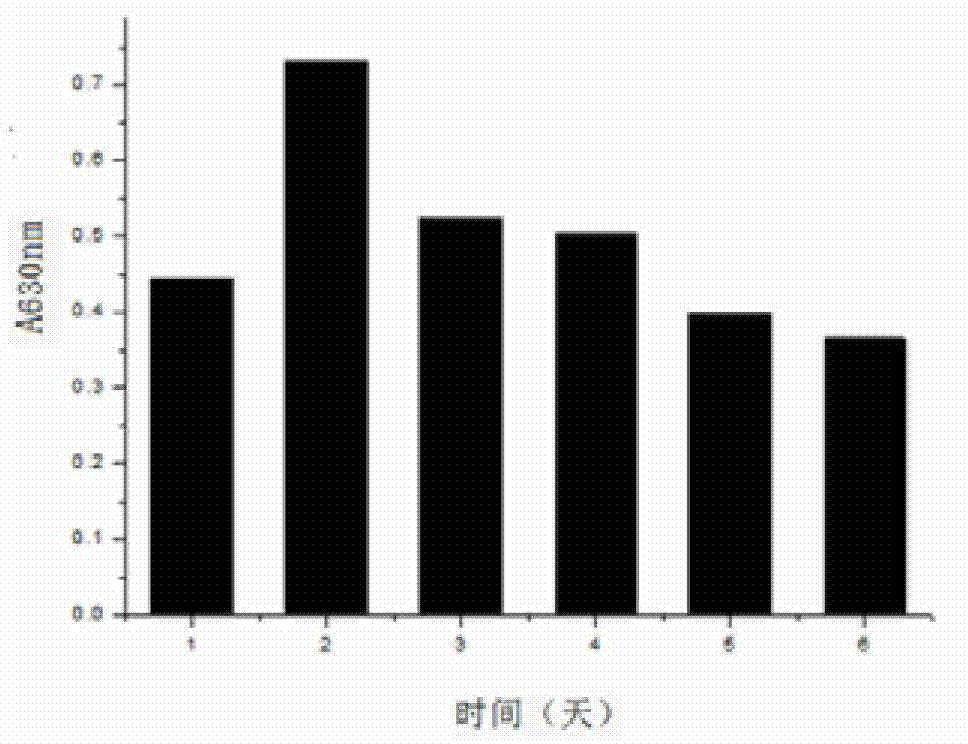

Embodiment 2

[0040] (1) Prepare the extraction solution: 0.08mol / L Na 2 HPO 4 / NaH 2 PO 4 , 0.15mol / L NaCl, 0.3mmol / L vitamin B 6 Or PLP, 30mg / L CaCl 2 , pH 5.7;

[0041] (2) Chop and grind the ripe whole banana, add 1L of extract solution to every 1kg of banana, stir evenly, and stand at room temperature for extraction for 4 hours;

[0042] (3) After centrifugation at 7000rpm for 10 minutes, the supernatant is glutamic acid decarboxylase solution;

[0043] (4) Add 500 mL of 20 g / L glutamic acid or sodium glutamate solution with a pH value of 4.5 to 5.5 to the glutamic acid decarboxylase solution, and stir at 150 r / min at 37°C for 1 to 2 hours, and then supplement every 1 hour. Add 3-5g of glutamic acid or sodium glutamate, control the pH value at 5.0-5.5, and repeat this until the enzyme activity disappears;

[0044] (5) After the reaction is completed, add 1% (w / v) activated carbon and stir at 37°C and 100r / min for 30min to decolorize;

[0045] ...

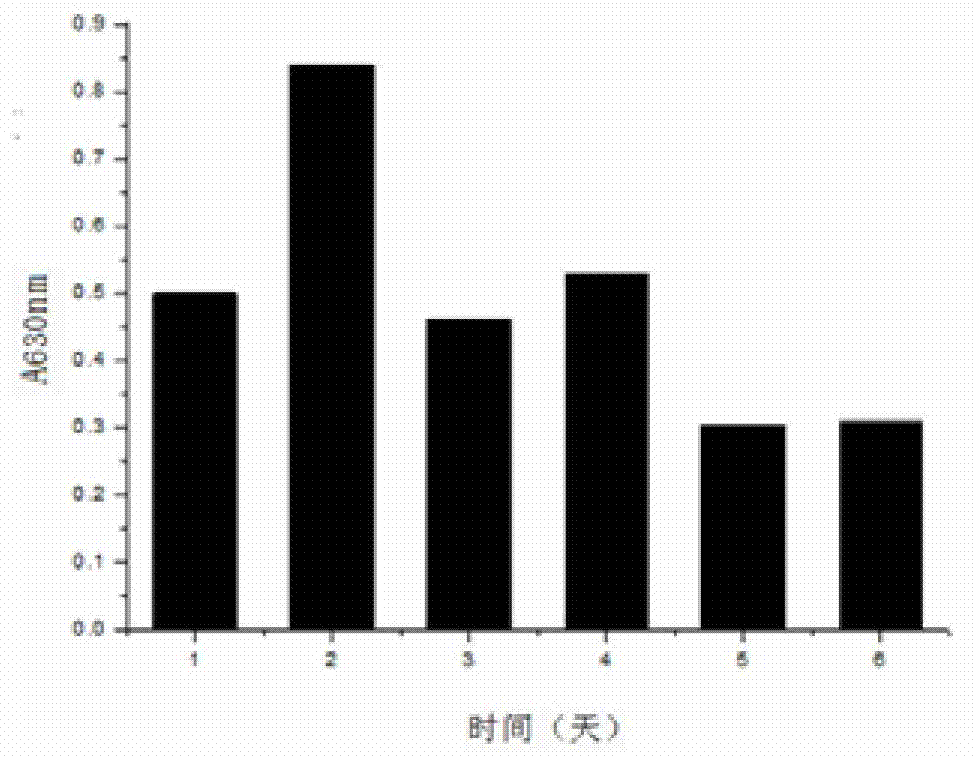

Embodiment 3

[0047] (1) Prepare the extraction solution: 0.05mol / L Na 2 HPO4 / NaH 2 PO 4 , 0.15mol / L NaCl, 0.3mmol / L vitamin B 6 Or PLP, 30mg / L CaCl 2 , pH 5.5;

[0048] (2) Chop and grind the ripe whole banana, add 1.5L of extracting solution to every 1kg of banana, stir evenly, and stand at room temperature for extraction for 4 hours;

[0049] (3) After centrifugation at 7000rpm for 8 minutes, the supernatant is glutamic acid decarboxylase solution;

[0050] (4) Add 10g of glutamic acid to the glutamic acid decarboxylase solution, the pH value is 5.0-5.5, at 37°C, stir at 120r / min for 1-2h, then add 3-5g of glutamic acid every 1h, the pH The value is controlled at 5.0-5.5, and this is repeated until the enzyme activity disappears;

[0051] (5) After the reaction is completed, add 1% (w / v) activated carbon and stir at 37°C and 120r / min for 60min to decolorize;

[0052] (6) Filtration, rotary steaming at 55°C until a small amount of crystals precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com