Production method of cubic MgZnO film

A technology of cubic structure and thin film, which is applied in the field of preparation of cubic structure MgZnO thin film, can solve problems such as phase separation of MgZnO thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention is achieved like this, a kind of preparation method of cubic structure MgZnO thin film is provided, and it comprises the steps:

[0025] S01: Prepare Mg 0.5 Zn 0.5 O target;

[0026] S02: Put the substrate into the chamber, heat the substrate to 400°C-500°C, feed oxygen with a flow rate of 10sccm-70sccm, make the chamber pressure 4-8Pa, and then use the Mg 0.5 Zn 0.5 O target material, pulse deposition is performed on the substrate to obtain the cubic structure MgZnO thin film.

[0027] Specifically, in step S01, the Mg 0.5 Zn 0.5 The size of the O target is Φ60×30 mm, and the target can be obtained commercially or prepared by existing techniques.

[0028] Step S02 specifically includes cutting the substrate into a size of 15×20 cm, and placing it in a PLD equipment growth chamber after cleaning. Put the Mg on the target holder 0.5 Zn 0.5 The O target is used as the source material, and the cleaned substrate is placed dir...

Embodiment 1

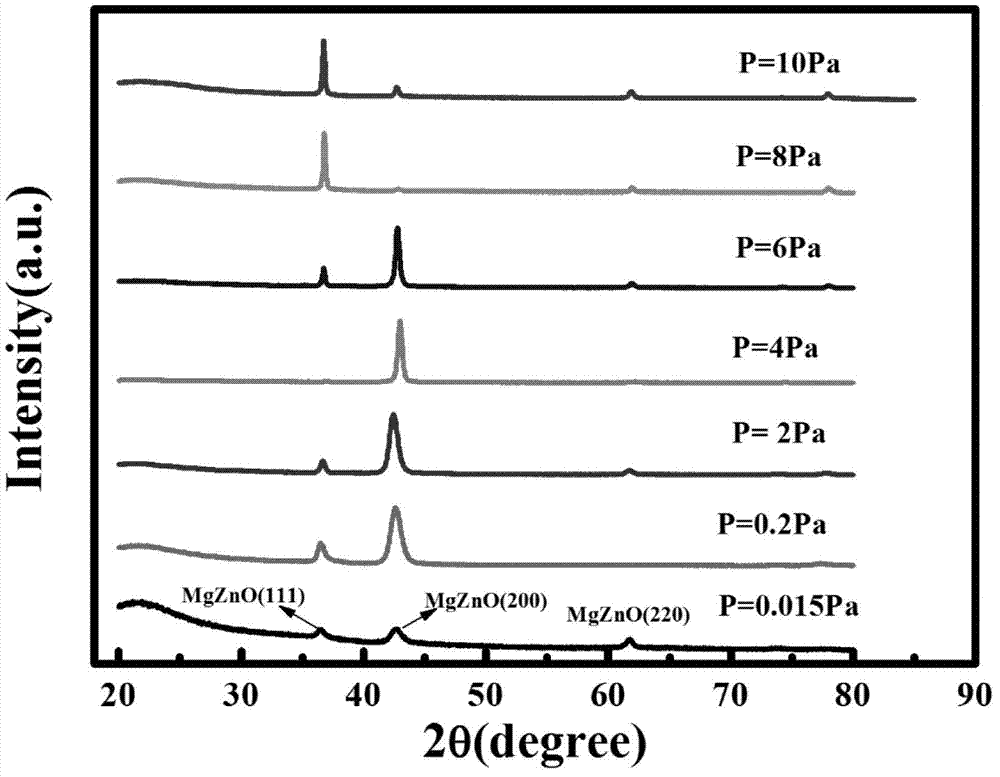

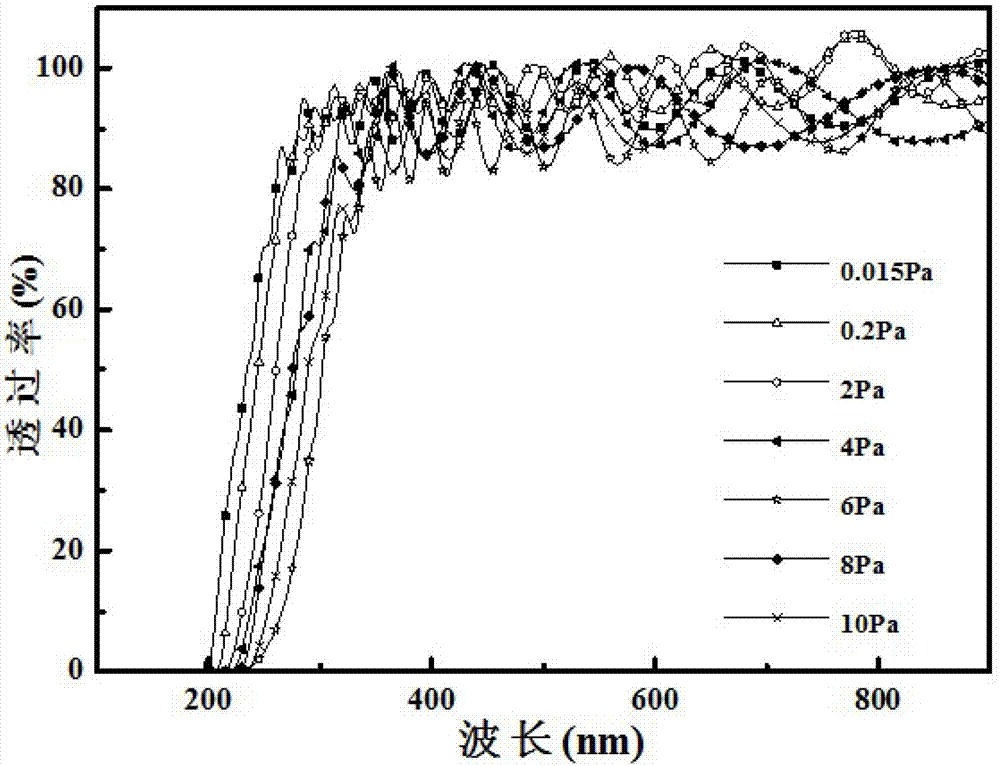

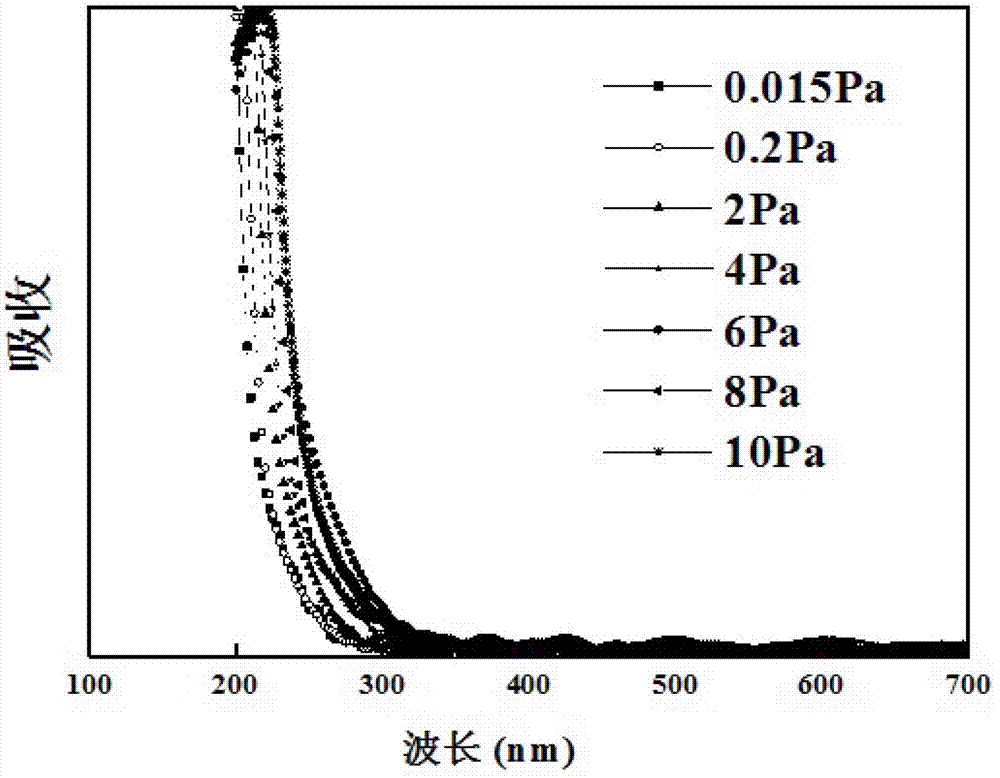

[0035] Put the cleaned substrate into the chamber sample holder, first draw the chamber to 5.0×10 -4 Pa background vacuum degree, substrate temperature 450 ℃ for growth. The oxygen flow rate is fixed at 30 sccm, and the films are grown under working pressures of 0.015Pa, 0.2Pa, 2Pa, 4Pa, 6Pa, 8Pa and 10Pa by changing the amount of oxygen pumped out of the vacuum chamber per unit time. During the growth process, the laser energy and laser frequency were respectively fixed at 300mJ, 5Hz, the substrate-target distance was 60mm, the substrate temperature was maintained at 450°C, and the growth time was 120min, and the samples were taken out at room temperature.

Embodiment 2

[0037] Put the cleaned substrate into the chamber sample holder, first draw the chamber to 5.0×10 -4 The background vacuum degree of Pa, the substrate temperature was raised to 450°C for pretreatment for 30min, and then the growth was carried out. By changing the oxygen flow, the oxygen flow was fixed at 10 sccm, 30 sccm, 50 sccm and 70 sccm, respectively. During the growth process, the laser energy and laser frequency were fixed at 300mJ and 5Hz respectively, the substrate temperature was kept at 450°C, and the growth time was 120min. The oxygen pressure was fixed at 8Pa by adjusting the amount of gas pumped out of the cavity per unit time. Cool down to room temperature and remove the sample.

[0038] The normalized X-ray diffraction (XRD) figure ( figure 1 ) shows that all the thin film samples are a single MgO cubic phase, and no diffraction peaks of the MgO hexagonal phase appear. There are (200), (220), and (111) cubic structure MgZnO in the grown MgZnO thin films. As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com