Sodium bismuth titanate-based 0-3 composite ferroelectric thick film and preparation method and application thereof

A bismuth sodium titanate-based, ferroelectric thick film technology is applied in the field of electronic functional materials and devices to achieve the effects of increasing thickness, increasing energy storage density and improving energy storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a

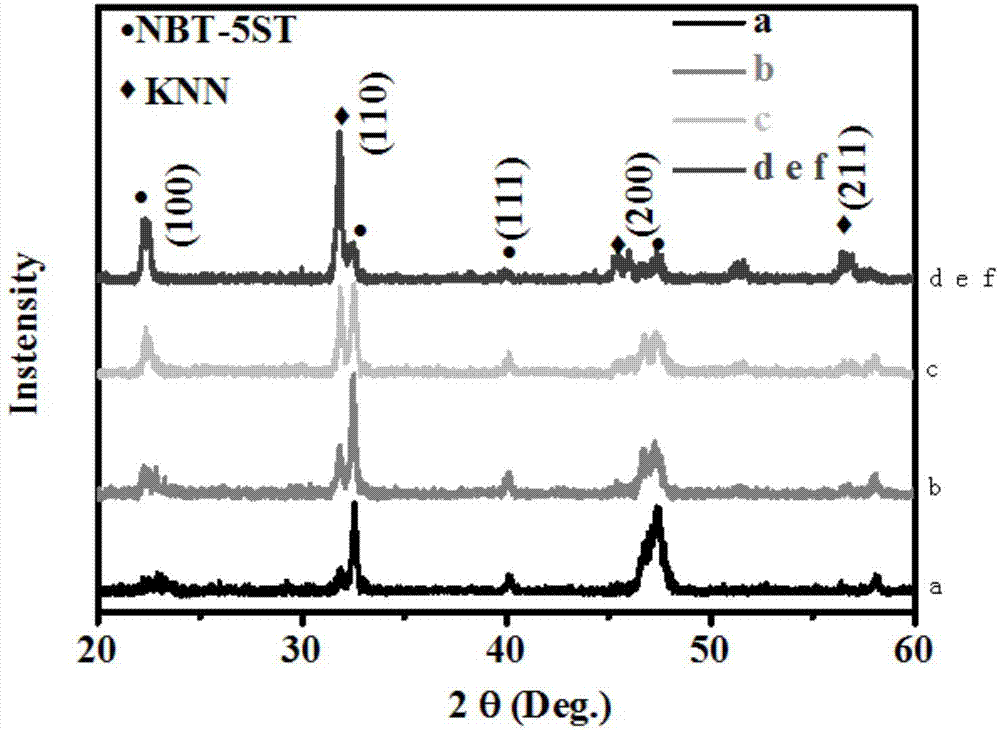

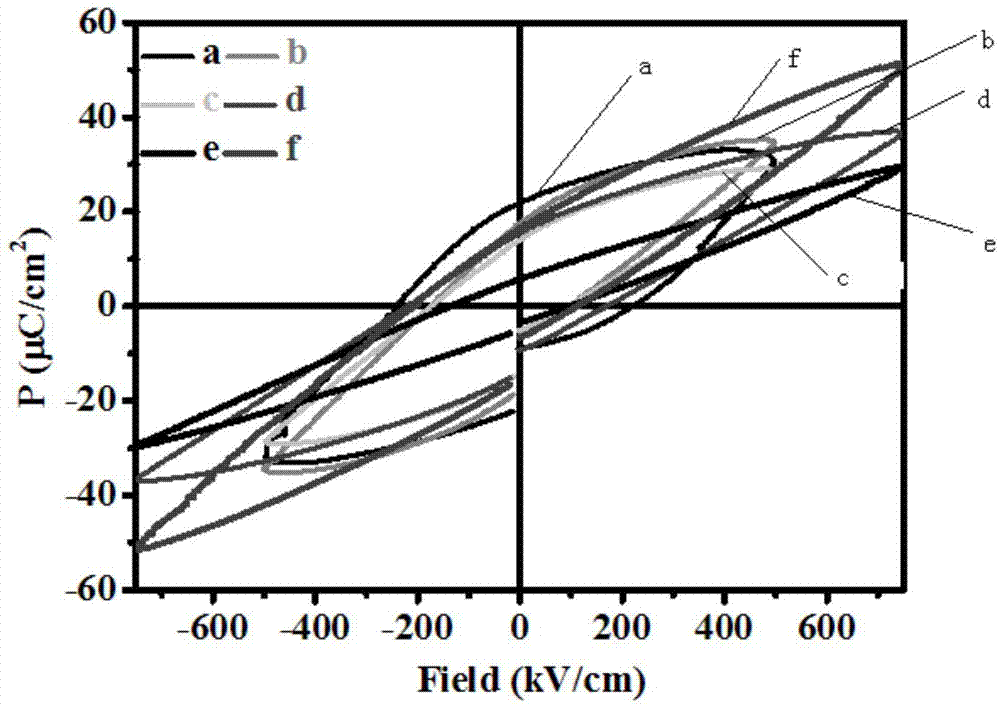

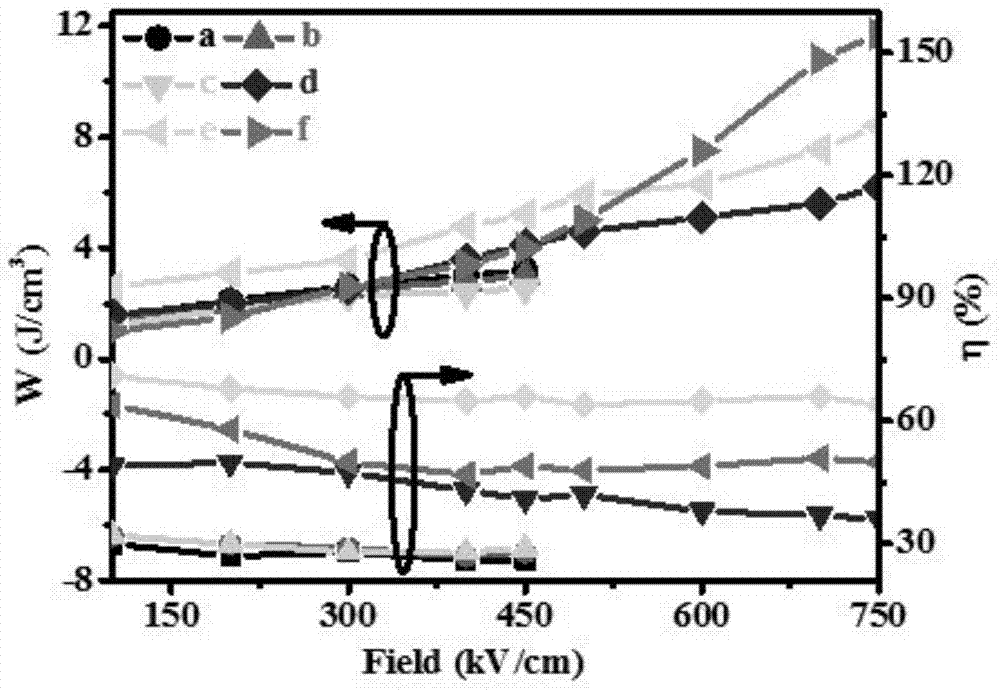

[0036] Embodiment a: (0.95Na 0.5 Bi 0.5 TiO 3 -0.05SrTiO 3 )-0.5(K 0.5 Na 0.5 )NbO 3 Composite ferroelectric thick film and its preparation

[0037] (1)(K 0.5 Na 0.5 )NbO 3 Powder preparation

[0038] 1) with NaCO 3 , Nb 2 o 5 and K 2 CO 3 as raw material, according to (K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio ingredients are dried after ball milling for 24 hours;

[0039] 2) Put the powder obtained in step 1) into a crucible, raise the temperature to 1000°C at a heating rate of 1°C-5°C / min, and hold the temperature for 4 hours;

[0040] 3) ball milling the powder obtained in step 2) for 24 hours again;

[0041] 4) The powder obtained in step 3) is centrifuged at a rotation speed of 500-700 r / min for 2 minutes.

[0042] (2) 0.95Na 0.5 Bi 0.5 T-0.05SrTiO 3 Colloid preparation

[0043] Dissolve sodium acetate, bismuth nitrate, strontium acetate and tetra-n-butyl titanate in ethylene glycol methyl ether, add chelating agent acetylacetone, drop into cat...

Embodiment b

[0051] Embodiment b: (0.95Na 0.5 Bi 0.5 TiO 3 -0.05SrTiO 3 )-0.8(K 0.5 Na 0.5 )NbO 3 Composite ferroelectric thick film and its preparation

[0052] (1)(K 0.5 Na 0.5 )NbO 3 Powder preparation

[0053] 1) with NaCO 3 , Nb 2 o 5 and K 2 CO 3 as raw material, according to (K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio ingredients are dried after ball milling for 24 hours;

[0054] 2) Put the powder obtained in step 1) into a crucible, raise the temperature to 1200°C at a heating rate of 1°C-5°C / min, and hold the temperature for 4 hours;

[0055] 3) ball milling the powder obtained in step 2) for 24 hours again;

[0056] 4) The powder obtained in step 3) is centrifuged at a rotation speed of 500-700 r / min for 2 minutes.

[0057] (2)(0.95Na 0.5 Bi 0.5 TiO 3 -0.05SrTiO 3 ) preparation of colloid

[0058] Dissolve sodium acetate, bismuth nitrate, strontium acetate and tetra-n-butyl titanate in ethylene glycol methyl ether, add chelating agent acetylacetone, dr...

Embodiment c

[0064] Embodiment c: (0.95Na 0.5 Bi 0.5 TiO 3 -0.05SrTiO 3 )-1.5(K 0.5 Na 0.5 )NbO 3 Composite ferroelectric thick film and its preparation

[0065] (1)(K 0.5 Na 0.5 )NbO 3 Powder preparation

[0066] 1) with NaCO 3 , Nb 2 o 5 and K 2 CO 3 as raw material, according to (K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio ingredients are dried after ball milling for 24 hours;

[0067] 2) Put the powder obtained in step 1) into a crucible, raise the temperature to 900°C at a heating rate of 1°C-5°C / min, and hold the temperature for 6 hours;

[0068] 3) ball milling the powder obtained in step 2) for 24 hours again;

[0069] 4) The powder obtained in step 3) is centrifuged at a rotation speed of 500-700 r / min for 2 minutes.

[0070] (2) 0.95Na 0.5 Bi 0.5 T-0.05SrTiO 3 Colloid preparation

[0071] Dissolve sodium acetate, bismuth nitrate, strontium acetate and tetra-n-butyl titanate in ethylene glycol methyl ether, add chelating agent acetylacetone, drop into cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com