Lead-free ferroelectric thick film and manufacturing method thereof

A technology of ferroelectric thick film and manufacturing method, which is applied to the parts of fixed capacitors and the dielectric of fixed capacitors, can solve the problems of difficult control of film thickness, low energy storage density and energy storage efficiency, and low breakdown electric field, and achieve Conducive to energy storage density, increase energy storage density, and increase energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment b

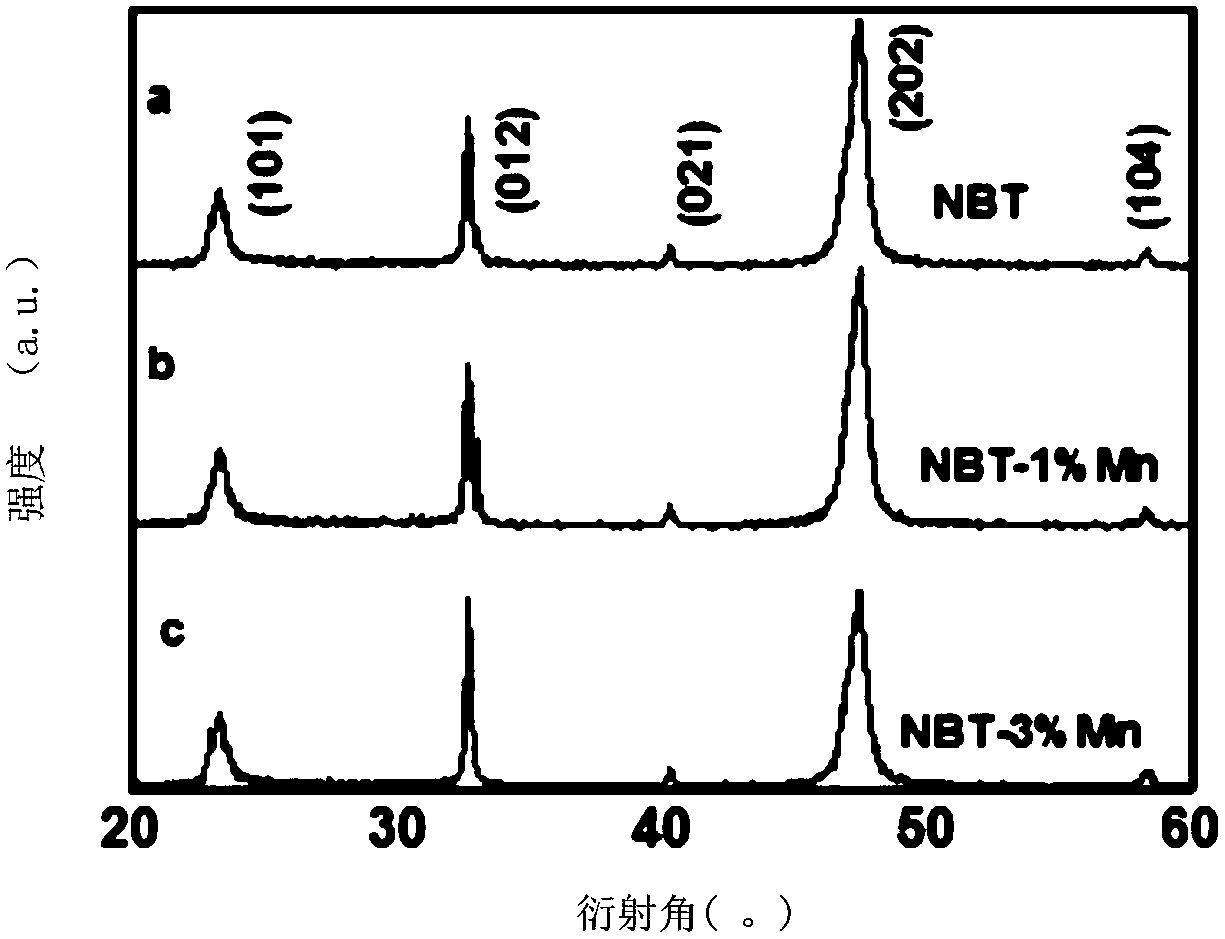

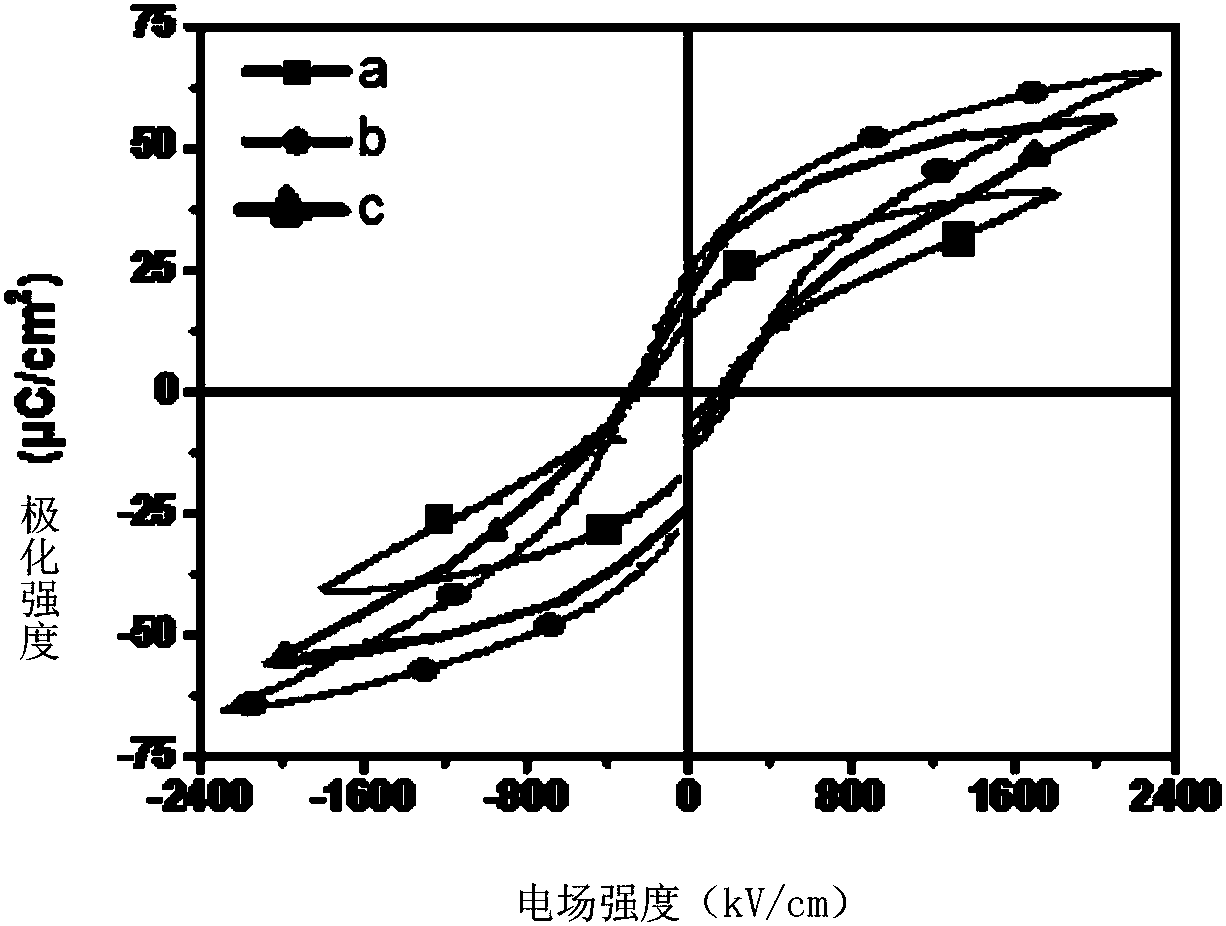

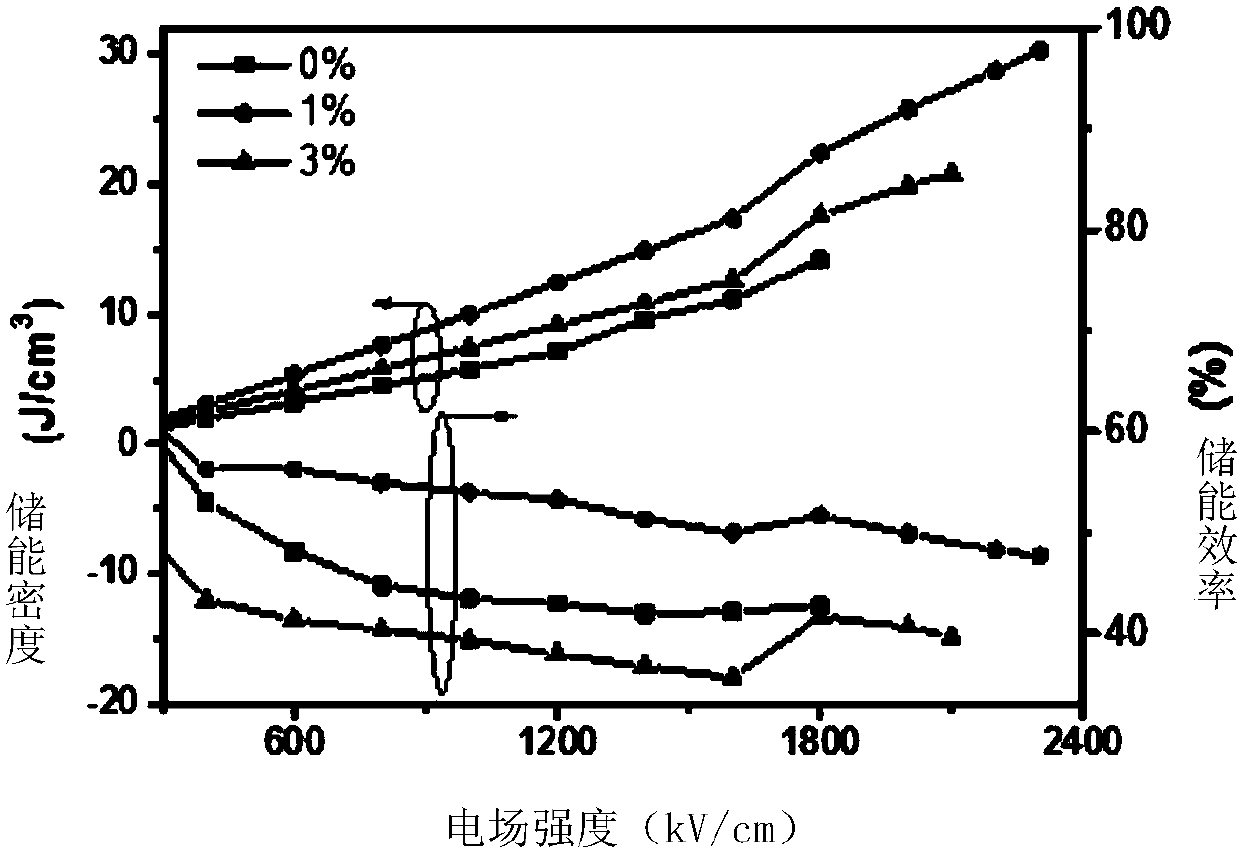

[0091] Example b: Na 0.5 Bi 0.5 Ti 0.99 mn 0.01 o 3 Composite ferroelectric thick film and its preparation

[0092] Preparation of LaNiO 3 Bottom electrode, as follows:

[0093] Nickel acetate and lanthanum nitrate are measured at a molar ratio of 1:1, and deionized water and acetic acid are added to a beaker at a mass ratio of 1:5 to make the concentration reach 0.3-0.6 mol / L. Heat and stir at 100°C for 30-40min with a constant temperature magnetic stirrer;

[0094] The solution was cooled to room temperature, and formamide was added to the solution at a molar ratio of 1:25 to obtain a stable colloid;

[0095] Filter with four layers of medium-speed quantitative filter paper to obtain LaNiO 3 colloid;

[0096] Clean the substrate according to the cleaning process, wipe it clean with alcohol cotton, dry it with an ear ball, and drop 2-3 drops of LaNiO with a dropper 3 The colloid is placed on the substrate, and the glue is shaken by an adjustable glue machine, the se...

Embodiment c

[0109] Example c: Na 0.5 Bi 0.5 Ti 0.97 mn 0.03 o 3 Composite ferroelectric thick film and its preparation

[0110] Preparation of LaNiO 3 Bottom electrode, as follows:

[0111] Nickel acetate and lanthanum nitrate are measured at a molar ratio of 1:1, and deionized water and acetic acid are added to a beaker at a mass ratio of 1:5 to make the concentration reach 0.3-0.6 mol / L. Heat and stir at 100°C for 30-40min with a constant temperature magnetic stirrer;

[0112] The solution was cooled to room temperature, and formamide was added to the solution at a molar ratio of 1:25 to obtain a stable colloid;

[0113] Filter with four layers of medium-speed quantitative filter paper to obtain LaNiO 3 colloid;

[0114] Clean the substrate according to the cleaning process, wipe it clean with alcohol cotton, dry it with an ear ball, and drop 2-3 drops of LaNiO with a dropper 3 The colloid is placed on the substrate, and the glue is shaken by an adjustable glue machine, the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com