Etching solution and etching method

A technology of corrosive liquid and ionic compounds, applied in the field of materials, can solve problems such as damage, scratches, corrosion and removal of mercury cadmium telluride thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An embodiment of the present invention provides an etching solution, which is used to corrode a CdZnTe substrate under a mercury cadmium telluride film. The etching solution includes a dissolving agent, a buffer and an oxidizing agent;

[0028] The dissolving agent is nitric acid or phosphoric acid, and each liter of the corrosion solution includes 85-110g of nitric acid or 50-75g of phosphoric acid;

[0029] The buffering agent is lactic acid or polyacrylic acid, and each liter of the corrosion solution includes 0.2-2.0 g of lactic acid or 4-8.0 g of polyacrylic acid;

[0030] The oxidizing agent is a permanganate ion compound or a dichromate ion compound, and each liter of the corrosion solution includes 60-90g of permanganate ion or 140-165g of dichromate ion.

[0031] The oxidizing agent in the embodiment of the present invention can also be the mixture of permanganate ion compound and dichromate ion compound, when the described oxidizing agent is the mixture of per...

Embodiment 2

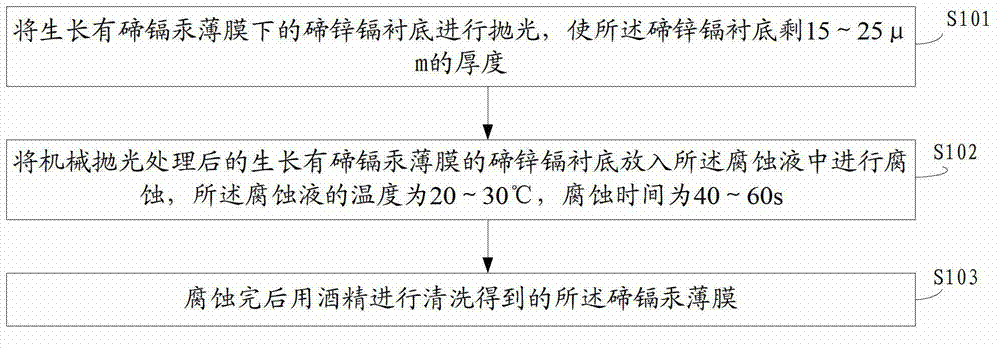

[0038] An embodiment of the present invention provides an etching method, which uses any of the etching solutions in the above embodiments for etching, see figure 1 , the method includes:

[0039] S101. Perform mechanical polishing and mechanochemical polishing on the CdZnTe substrate grown under the HgCdTe film, so that the CdZnTe substrate has a thickness of 15-25 μm;

[0040] S102. Put the mechanically polished CdZnTe substrate with the HgCdTe film grown on it into the etching solution for etching, the temperature of the etching solution is 20-30°C, and the etching time is 40-90s;

[0041] S103, the mercury cadmium telluride thin film obtained by cleaning with alcohol after etching.

[0042] Wherein, the crystal orientation of the cadmium zinc telluride substrate in the embodiment of the present invention is or , and the composition is Cd 0.96 Zn 0.04 Te, the mercury cadmium telluride thin film is obtained on the surface of the cadmium zinc telluride substrate by liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com