A kind of diffusion film and preparation method thereof

A diffusion film and diffusion layer technology, applied in polyurea/polyurethane coatings, diffusing elements, coatings, etc., can solve the problems of human physiological disease hazards, solvent is not easy to discharge, human body hazards still exist, etc. Harmful, reduce fire safety hazards, obvious effect of green environmental protection significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

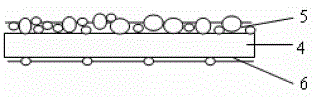

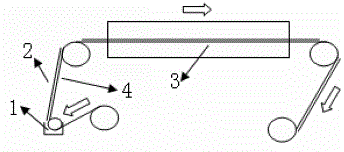

[0030] Water-based polyurethane resin emulsion (bayer, polyurethane dispersion, XP2558, solid content 37%) 88 parts, water-based crosslinking agent (hydrophilic aliphatic isocyanate, bayer, VPLS2319) 8 parts, defoamer (siloxane , BYK-045) 0.2 parts, wetting and dispersing agent (alkanol ammonium salt of multifunctional polymer, BYK-181) 0.8 parts, diffusion particles (PMMA, Sekisui MBX-5) 3 parts, after mixing and stirring, carry out Anti-adhesive coating, dry and ready to use.

[0031] 70 parts of water-based polyurethane resin emulsion (bayer, polyurethane dispersion, XP2558, solid content of 37%), 6 parts of water-based crosslinking agent (hydrophilic aliphatic isocyanate, bayer, VPLS2319), defoamer (siloxane , BYK-045) 0.2 parts, wetting and dispersing agent (alkanol ammonium salt of multifunctional polymer, BYK-181) 3.7 parts, diffusion particles (PMMA, Sekisui MBX-10) 10 parts, diffusion particles (PMMA, After mixing and stirring 10 parts of Sekisui MBX-12), the diffusi...

Embodiment 2

[0033] Water-based polyacrylic resin emulsion (bayer, water-based hydroxyacrylic dispersion, XP2427, solid content 42%) 85 parts, water-based crosslinking agent (hydrophilic aliphatic isocyanate, bayer, VPLS2151) 8.5 parts, defoamer (silicon Oxygen, BYK-045) 0.2 parts, wetting and dispersing agent (block copolymer with affinity group, BYK-190) 1.3 parts, diffusion particles (PMMA, Sekisui MBX-5) 5 parts, mix and stir Afterwards, anti-adhesive layer coating is carried out, and it is ready to use after drying.

[0034]70 parts of water-based polyacrylic resin emulsion (bayer, water-based hydroxyacrylic dispersion, XP2427, solid content of 42%), 6 parts of water-based crosslinking agent (hydrophilic aliphatic isocyanate, bayer, VPLS2151), defoamer (silicon Oxylkane, BYK-045) 0.2 parts, wetting and dispersing agent (block copolymer with affinity group, BYK-190) 3.8 parts, diffusion particles (PMMA, Sekisui MBX-15) 20 parts after mixing and stirring , carry out the diffusion layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com