Fresh wet surface browning inhibitor and application thereof

A technology for fresh and wet noodles and an inhibitor, which is applied in the field of flour processing, can solve the problems of complex preparation methods, many inhibitor compositions and formulas, unfavorable health, etc., and achieves simple components and preparation methods, comprehensive and thorough inhibitory effect, and does not affect nutrition. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Fully dissolve 0.5g of thiamine, 1g of L-cysteine, and 3g of ascorbic acid in clean water, then add clean water to a solution with a total mass of 1000g, fully stir and mix to obtain a browning inhibitor product.

[0018] Take 1000g of ordinary flour / whole wheat flour (commercially available Beiye brand flour), 10g of table salt, and 300g of the above-mentioned browning inhibitor finished product and put them into the dough mixer. Dough, let the dough rest for 30 minutes, roll it 4 times to form dough sheets, and prepare the dough sheets into ordinary fresh wet noodles (or whole wheat fresh wet noodles) with a width of 2 mm and a thickness of 1 mm through conventional noodle-making processes such as slitting and cutting. Store in a ziplock bag at 4°C.

Embodiment 2

[0020] Fully dissolve 1g of thiamine, 2g of L-cysteine, and 5g of ascorbic acid in clean water, then add clean water to a solution with a total mass of 1000g, stir and mix well to obtain a browning inhibitor product.

[0021] Take 1000g of ordinary flour / whole wheat flour (commercially available Beiye brand flour), 10g of table salt, and 300g of the above-mentioned browning inhibitor finished product and put them into the dough mixer. Dough, let the dough rest for 30 minutes, roll it 4 times to form dough sheets, and prepare the dough sheets into ordinary fresh wet noodles (or whole wheat fresh wet noodles) with a width of 2 mm and a thickness of 1 mm through conventional noodle-making processes such as slitting and cutting. Store in a ziplock bag at 4°C.

Embodiment 3

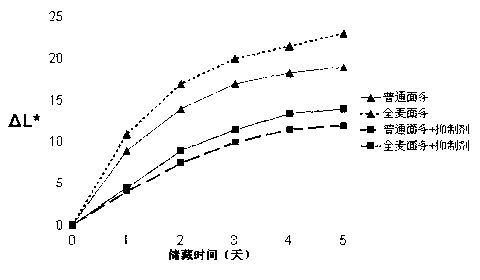

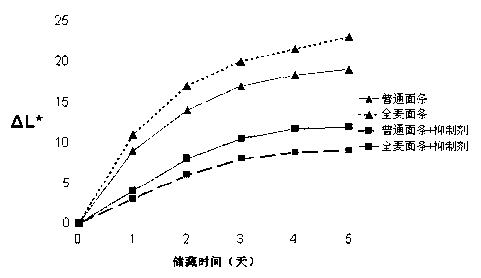

[0022] Example 3 Determination and comparison of flour tyrosinase activity and noodle browning degree

[0023] 1. Tyrosinase activity assay

[0024] Mainly measure the activity of diphenolase in flour. According to the ratio of thiamine, L-cysteine and ascorbic acid shown in Table 1, the browning inhibitors (experimental groups: the 2nd to 7th groups) were made respectively; 0.05g of the above-mentioned browning inhibitors, 5g Ordinary flour / whole wheat flour (commercially available Beiye brand flour) and 25ml contains 1.0×10 -3 5.0×10 mol / l levodopa (substrate) -3 Add the mol / l MOPS buffer solution into a 50ml centrifuge tube, mix well and incubate at 20°C for 1 hour, then centrifuge at 8000g for 3 minutes, collect the supernatant, and measure it with a spectrophotometer (product of Shanghai Mapida Company, model UV-1800) The absorbance value of the above supernatant at 475nm, the blank value without substrate, and the enzyme activity are represented by Δ475 / min·g; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com