Flushing system and method for cleaning local sedimentation in nuclear power plant

A technology for flushing systems and nuclear power plants, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., which can solve the problems of waste of resources, inability to measure pressure difference, inaccurate measurement of pressure difference, etc., and achieve economical savings. The effect of water use, improved operational safety, and increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

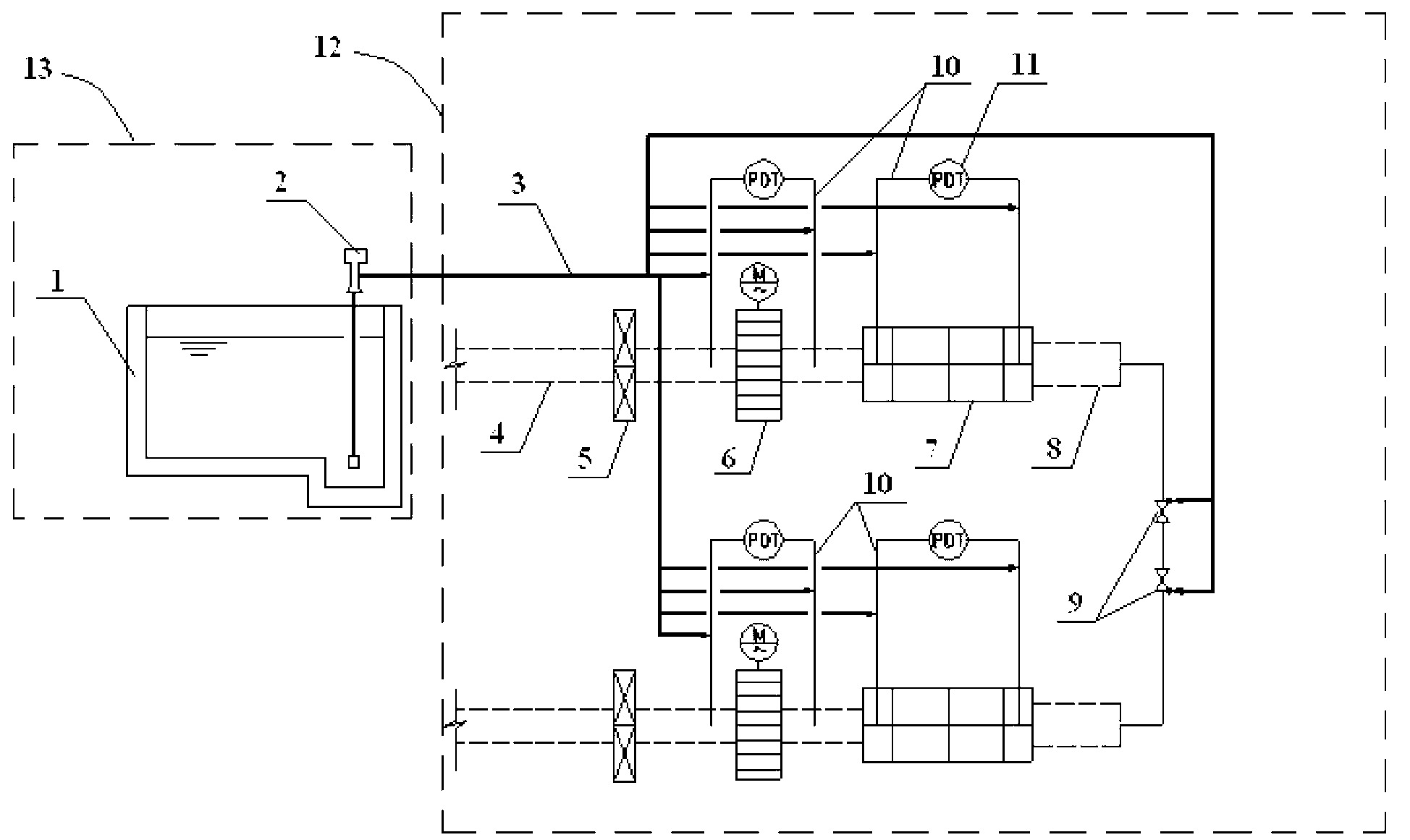

[0016] Such as figure 1 As shown, the desalinated water plant 13 is usually installed in the nuclear power plant, and the pretreatment process of the desalted water plant 13 generally adopts ultrafiltration treatment, and the waste water after the ultrafiltration treatment is used to flush the circulating water and important plant water in the pump room of the nuclear power plant System, circulating water and some pipelines in the important plant water system are located in the water intake pump room 12.

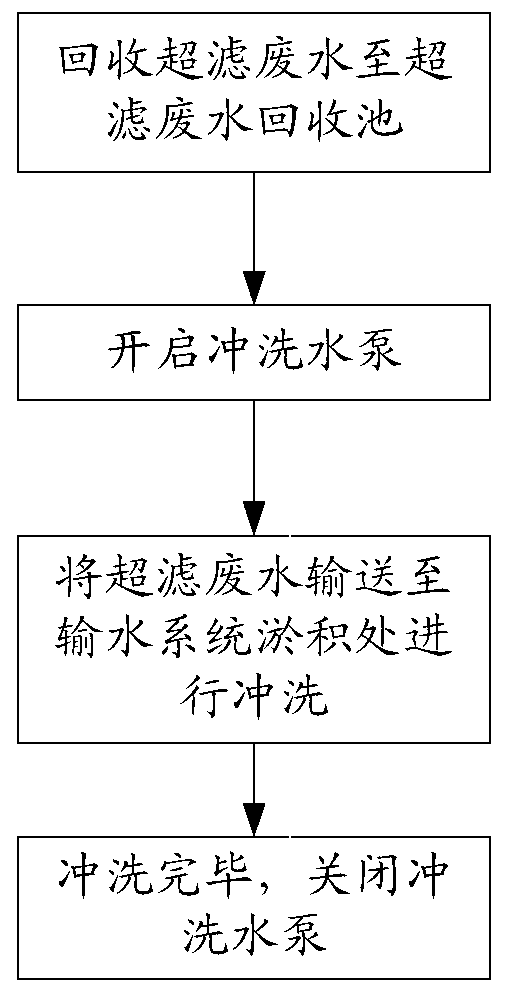

[0017] A flushing system for cleaning local deposits in nuclear power plants provided by the present invention includes an ultrafiltration wastewater recovery pool 1 and a flushing water pump 2 arranged in a desalinated water plant 13, the inlet end of the flushing water pump 2 and the ultrafiltration wastewater recovery pool 1 connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com