Automatic-door threaded rod and anti-friction coating thereof as well as spraying method of anti-friction coating

An anti-friction coating and automatic door technology, applied in coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high maintenance costs, difficult maintenance, and short maintenance cycles, and achieve low production costs and self-lubricating Excellent performance and wear resistance, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

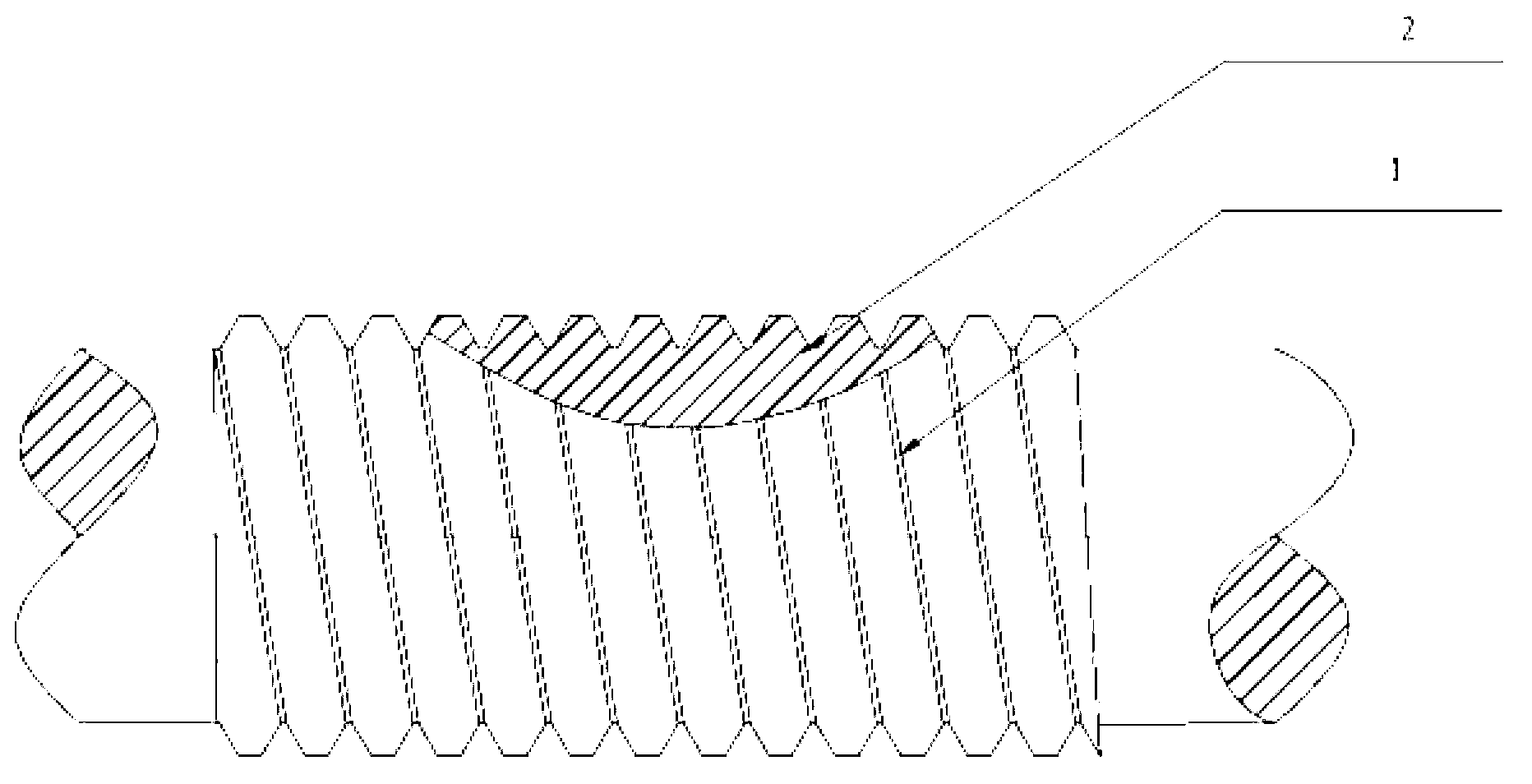

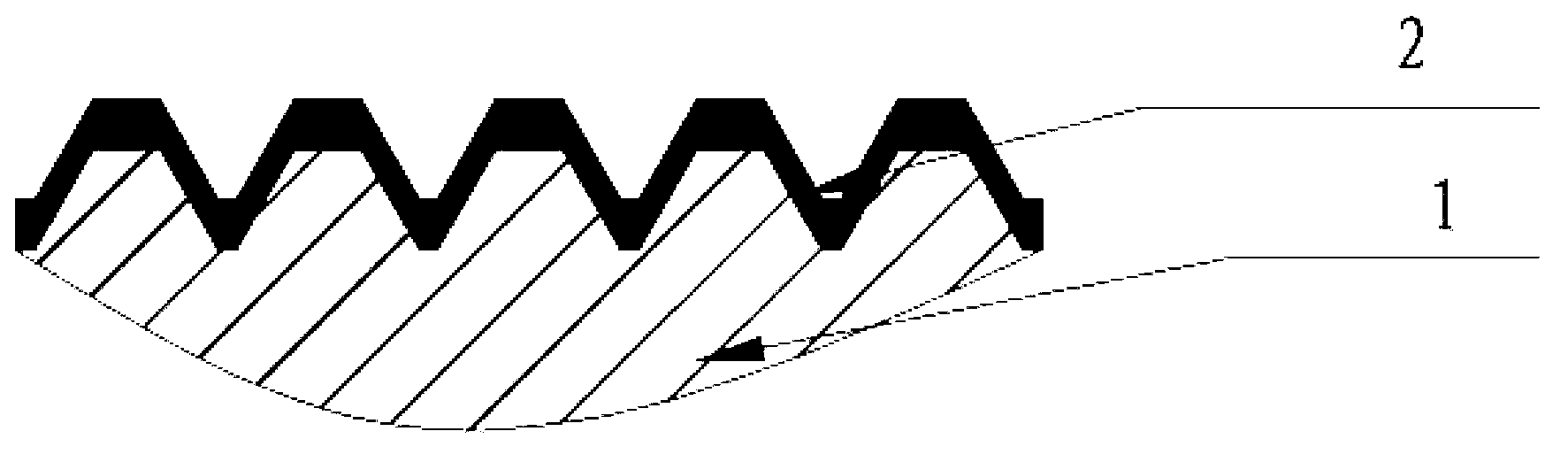

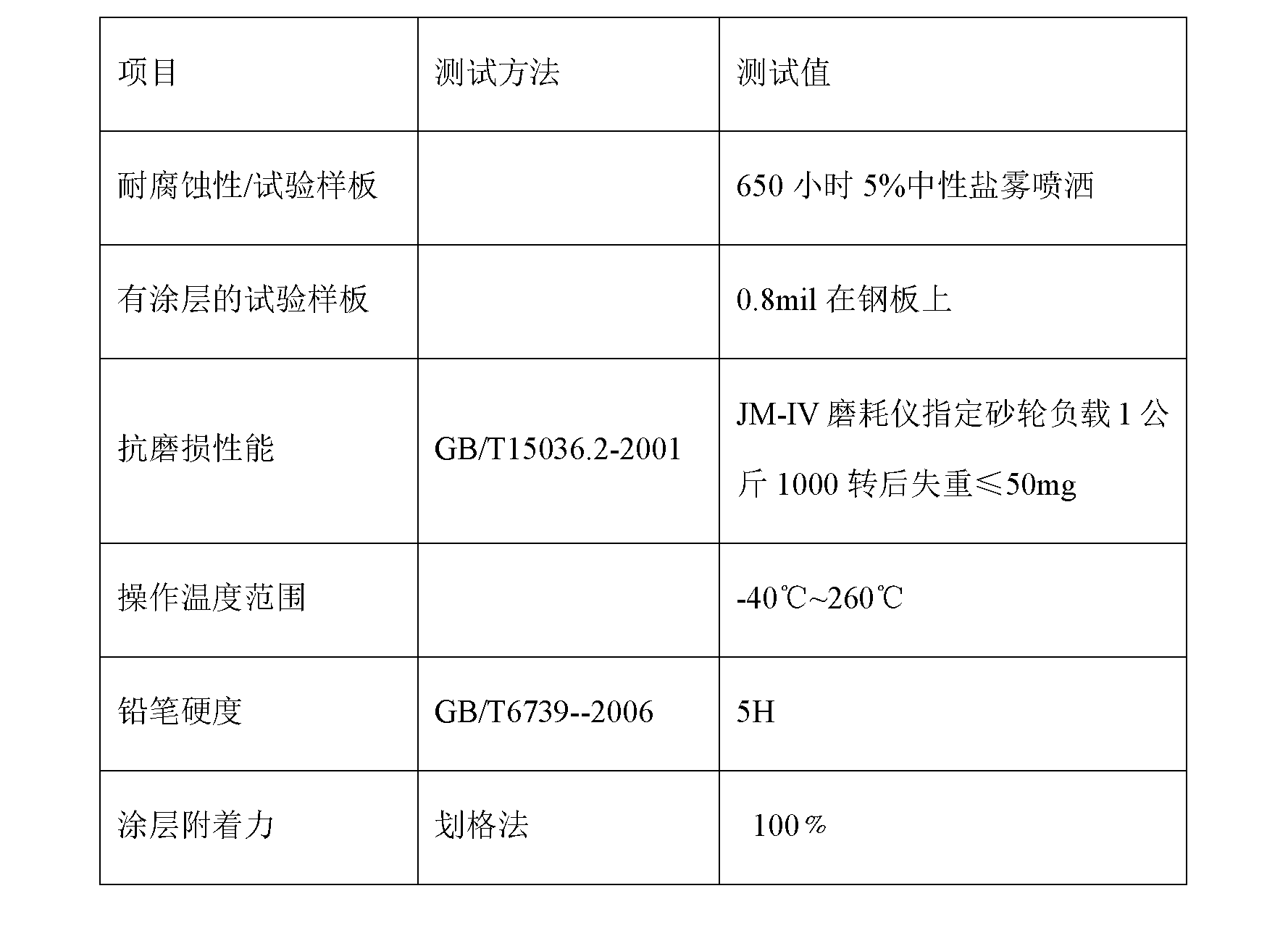

[0020] Anti-friction coating The automatic door screw of rail vehicles is composed of a metal substrate and an anti-friction coating, and the surface of the metal substrate is coated with an anti-friction coating, which constitutes the working layer of the screw; anti-friction coating The composition of the layer includes main material composite polymer material, composite solid lubricant, composite solid anti-wear agent and additives.

[0021] The formulation of the anti-friction coating is as follows:

[0022] Solid lubricant: 5% molybdenum disulfide, 12% graphite, 2% graphite fluoride, 6% tungsten disulfide, 2% molybdenum diselenide;

[0023] The wear-resistant agent is: 1% nano-diamond, 3% silicon nitride, 6% aluminum oxide, 3% silicon dioxide, 2% antimony trioxide, 11% silicon carbide, 1% carbon nanotubes;

[0024] Additive: powder surface treatment agent 8%;

[0025] Adhesive: 15% polyester resin, 10% epoxy resin, 13% acrylic resin;

[0026] After mixing, the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com