Method and device for preparing high-purity and high-activity aluminium shots

A high-activity aluminum bean technology, applied in the field of aluminum bean preparation, can solve the problems of reducing activity and achieve the effects of low production cost, guaranteed purity and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

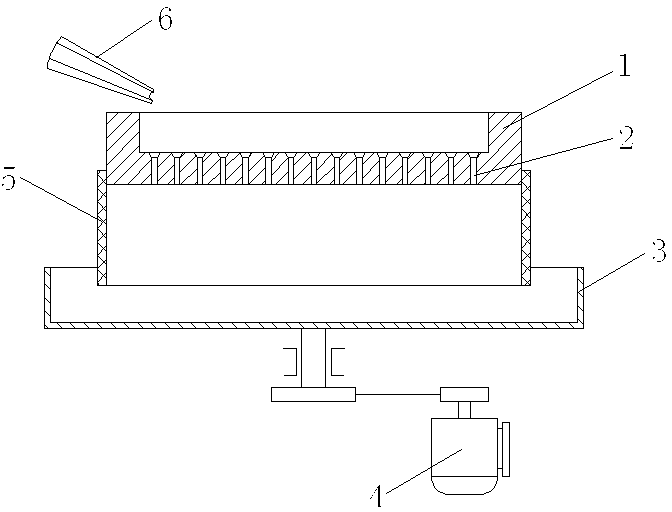

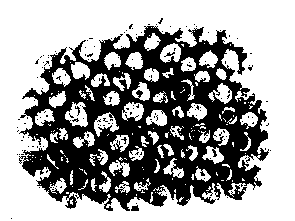

[0021] like figure 1 As shown, the aluminum liquid melted in the aluminum melting furnace with a temperature of about 780°C is introduced through the diversion groove 6 into the aluminum bean preparation mold 1 with holes 2 uniformly distributed at the bottom, and the diameter of the aluminum liquid on the aluminum bean preparation mold is The 0.2mm hole falls into the cooling rotating disk 3 installed at the lower part of the aluminum bean preparation mold. The high-temperature aluminum liquid is rapidly cooled by the cooling water installed in the cooling rotating disk. The cooling speed is 1000 degrees per minute, and the rotating disk is cooled at the same time Rotate at a speed of 2 rpm to make the high-temperature aluminum liquid form as figure 2 The shown aluminum beans have an average particle size of 10mm and a height-to-diameter ratio of about 1:1.5. After collecting the aluminum beans in the cooling rotating disk, they are finished aluminum beans; The distance bet...

Embodiment 2

[0023] like figure 1 As shown, the molten aluminum with a temperature of about 820°C after melting in the aluminum melting furnace is introduced into the aluminum bean preparation mold 1 with holes 2 evenly distributed at the bottom through the diversion groove 6, and the diameter of the aluminum liquid on the aluminum bean preparation mold through the aluminum bean is The 0.4mm hole falls into the cooling rotating disk 3 installed at the lower part of the aluminum bean preparation mold. The distance between the bottom surface of the aluminum bean preparation mold and the cooling liquid surface in the cooling rotating disk is 100mm; the high temperature aluminum liquid passes through the cooling rotating disk The water used for cooling in the cooling chamber is rapidly cooled, the cooling speed is 600 degrees per minute, and the cooling rotating disk is rotated at a speed of 4 revolutions per minute, so that the high temperature aluminum liquid is formed as figure 2 The shown...

Embodiment 3

[0025] like figure 1 As shown, the molten aluminum with a temperature of about 860°C after melting in the aluminum melting furnace is introduced into the aluminum bean preparation mold 1 with holes 2 evenly distributed at the bottom through the diversion groove 6, and the diameter of the aluminum liquid on the aluminum bean preparation mold is The 0.5mm hole falls into the cooling rotating disk 3 installed at the lower part of the aluminum bean preparation mold. The distance between the bottom surface of the aluminum bean preparation mold and the cooling liquid surface in the cooling rotating disk is 200mm; the high temperature aluminum liquid passes through the cooling rotating disk The water used for cooling in the cooling chamber is rapidly cooled at a cooling rate of 100 degrees per minute, while the cooling rotating disk rotates at a speed of 3 revolutions per minute, so that the high-temperature aluminum liquid forms as figure 2 The aluminum beans shown have an average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com