Near ultraviolet excitation type red phosphor and preparation method thereof

A technology for red phosphors and phosphors, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of single preparation method and low luminous intensity, and achieve the effects of unique preparation method, good luminescence performance and easy doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

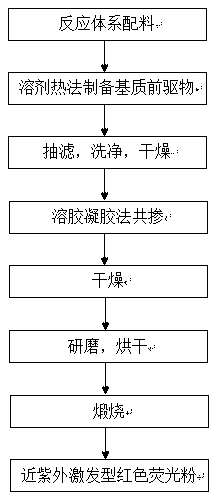

Method used

Image

Examples

Embodiment 1

[0021] According to the formula (Y 0.9 ,Gd 0.1 ) 0.96 (P 0.1 ,V 0.9 )O 4 : 0.02Eu 3+ ,0.02Bi 3+ Weigh Y separately 2 o 3 (A.R.) 0.216 mol, Eu 2 o 3 (A.R.) 0.005 mol, Bi(NO 3 ) 3 · 5H 2 O (A.R.) 0.01 mol, NH 4 VO 3 (A.R.) 0.45 mol, Gd 2 o 3 (A.R.) 0.024 mol and (NH 4 ) 2 HPO 4 (A.R.) 0.05 mol, and then weigh 1wt% surfactant PEG and 1wt% flux H 3 BO 3 ; put Y 2 o 3 and Eu 2 o 3 Heat and dissolve with an appropriate amount of concentrated nitric acid to form a solution, add Bi(NO 3 ) 3 · 5H 2 O and NH 4 VO 3 , and use a 1:1 water-alcohol mixed solution to form a solution, move the ultrasonically treated solution into a reaction kettle and heat it at 150 ° C for 18 hours, filter it with suction, wash it, and dry it to obtain a precursor; Gd 2 o 3 and (NH 4 ) 2 HPO 4Dissolve in excess dilute nitric acid, and then dry; dissolve the dry product in an appropriate amount of water-alcohol mixture, add the previously prepared precursor and surfact...

Embodiment 2

[0023] According to the formula (Y 0.8 ,Gd 0.2 ) 0.94 (P 0.2 ,V 0.8 )O 4 : 0.02Eu 3+ ,0.04Bi 3+ Weigh Y separately 2 o 3 (A.R.) 0.188 mol, Eu 2 o 3 (A.R.) 0.005 mol, Bi(NO 3 ) 3 · 5H 2 O (A.R.) 0.02 mol, NH 4 VO 3 (A.R.) 0.4 mol, Gd 2 o 3 (A.R.) 0.047 mol and (NH 4 ) 2 HPO 4 (A.R.) 0.1 mol, and then weigh 2wt% surfactant PEG and 1wt% flux BaF 2 ; put Y 2 o 3 and Eu 2 o 3 Heat and dissolve with an appropriate amount of concentrated nitric acid to form a solution, add Bi(NO 3 ) 3 · 5H 2 O and NH 4 VO 3 , and use a 1:1 water-alcohol mixed solution to form a solution, move the ultrasonically treated solution into a reaction kettle and heat it at 160 °C for 16 hours, filter it with suction, wash it, and dry it to obtain a precursor; Gd 2 o 3 and (NH 4 ) 2 HPO 4 Dissolve in excess dilute nitric acid, and then dry; dissolve the dry product in an appropriate amount of water-alcohol mixture, add the previously prepared precursor and surfactant PE...

Embodiment 3

[0025] According to the formula (Y 0.7 ,Gd 0.3 ) 0.94 (P 0.3 ,V 0.7 )O 4 : 0.04Eu 3+ ,0.02Bi 3+ Weigh Y separately 2 o 3 (A.R.) 0.1645 mol, Eu 2 o 3 (A.R.) 0.01 mol, Bi(NO 3 ) 3 · 5H 2 O (A.R.) 0.01 mol, NH 4 VO 3 (A.R.) 0.35 mol, Gd 2 o 3 (A.R.) 0.0705 mol and (NH 4 ) 2 HPO 4 (A.R.) 0.15 mol, and then weigh 3wt% surfactant PEG and 1wt% flux Li 2 CO 3 ; put Y 2 o 3 and Eu 2 o 3 Heat and dissolve with an appropriate amount of concentrated nitric acid to form a solution, add Bi(NO 3 ) 3 · 5H 2 O and NH 4 VO 3 , and use a 1:1 water-alcohol mixed solution to form a solution, move the ultrasonically treated solution into a reaction kettle and heat it at 180°C for 15 hours, filter it with suction, wash it, and dry it to obtain a precursor; Gd 2 o 3 and (NH 4 ) 2 HPO 4 Dissolve in excess dilute nitric acid, and then dry; dissolve the dry product in an appropriate amount of water-alcohol mixture, add the previously prepared precursor and surfact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com