Patents

Literature

88 results about "Activator (phosphor)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In phosphors and scintillators, the activator is the element added as dopant to the crystal of the material to create desired type of nonhomogeneities. In luminescence, only a small fraction of atoms, called emission centers or luminescence centers, emit light. In inorganic phosphors, these inhomogeneities in the crystal structure are created usually by addition of a trace amount of dopants, impurities called activators. (In rare cases dislocations or other crystal defects can play the role of the impurity.) The wavelength emitted by the emission center is dependent on the atom itself, its electronic configuration, and on the surrounding crystal structure.

Oxynitide phosphor and production process thereof, and light-emitting device using oxynitride phosphor

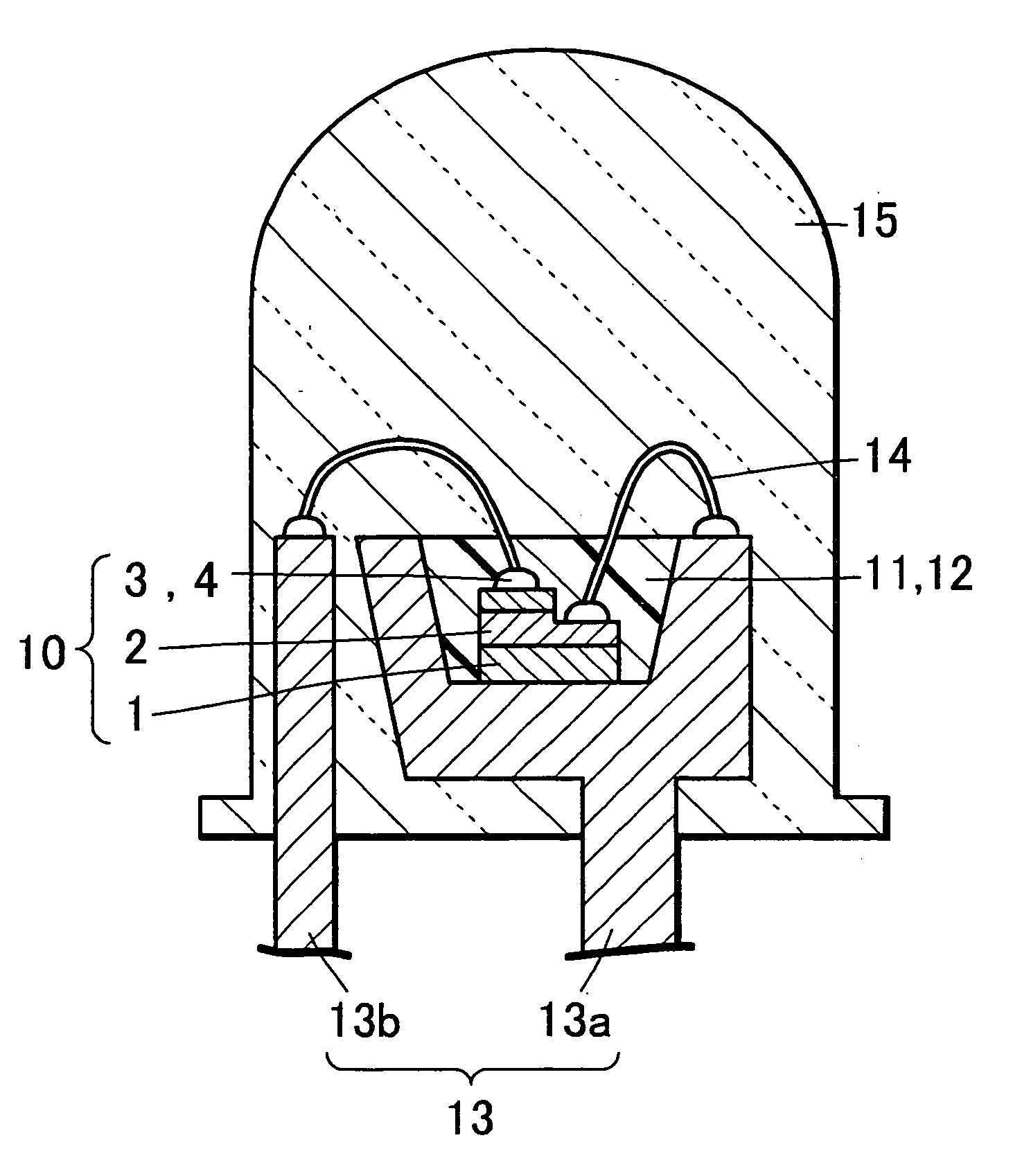

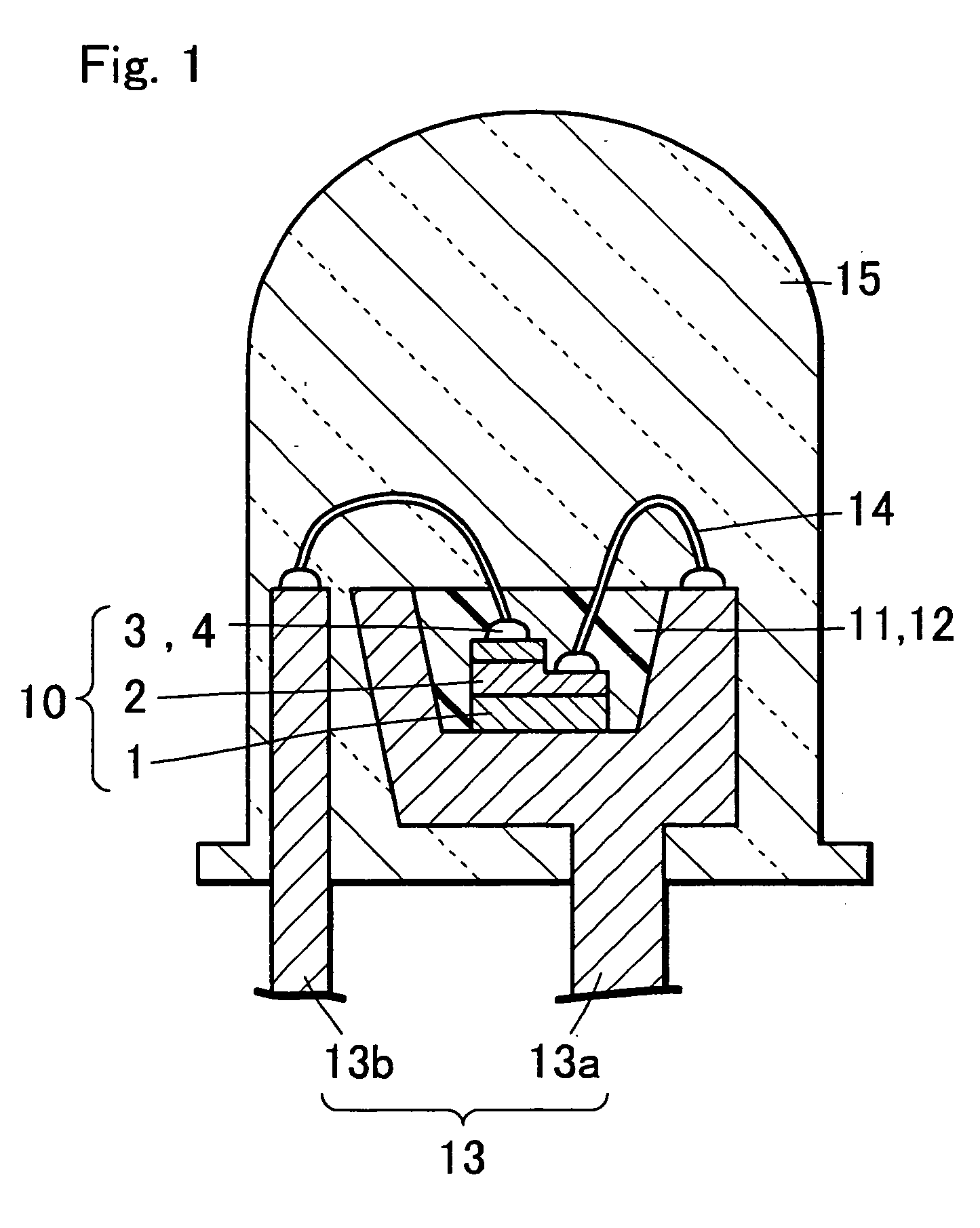

ActiveUS20060076883A1Good colorImprove luminous performanceDischarge tube luminescnet screensLamp detailsRare-earth elementFluorescence

An oxynitride phosphor consisting of a crystal containing at least one or more of Group II elements selected from the group consisting of Be, Mg, Ca, Sr, Ba and Zn, at least one or more of Group IV elements selected from the group consisting of C, Si, Ge, Sn, Ti, Zr and Hf, and a rare earth element being an activator R, thereby providing a phosphor which is excited by an excitation light source at an ultraviolet to visible light region and which has a blue green to yellow luminescence color that is wavelength converted.

Owner:NICHIA CORP

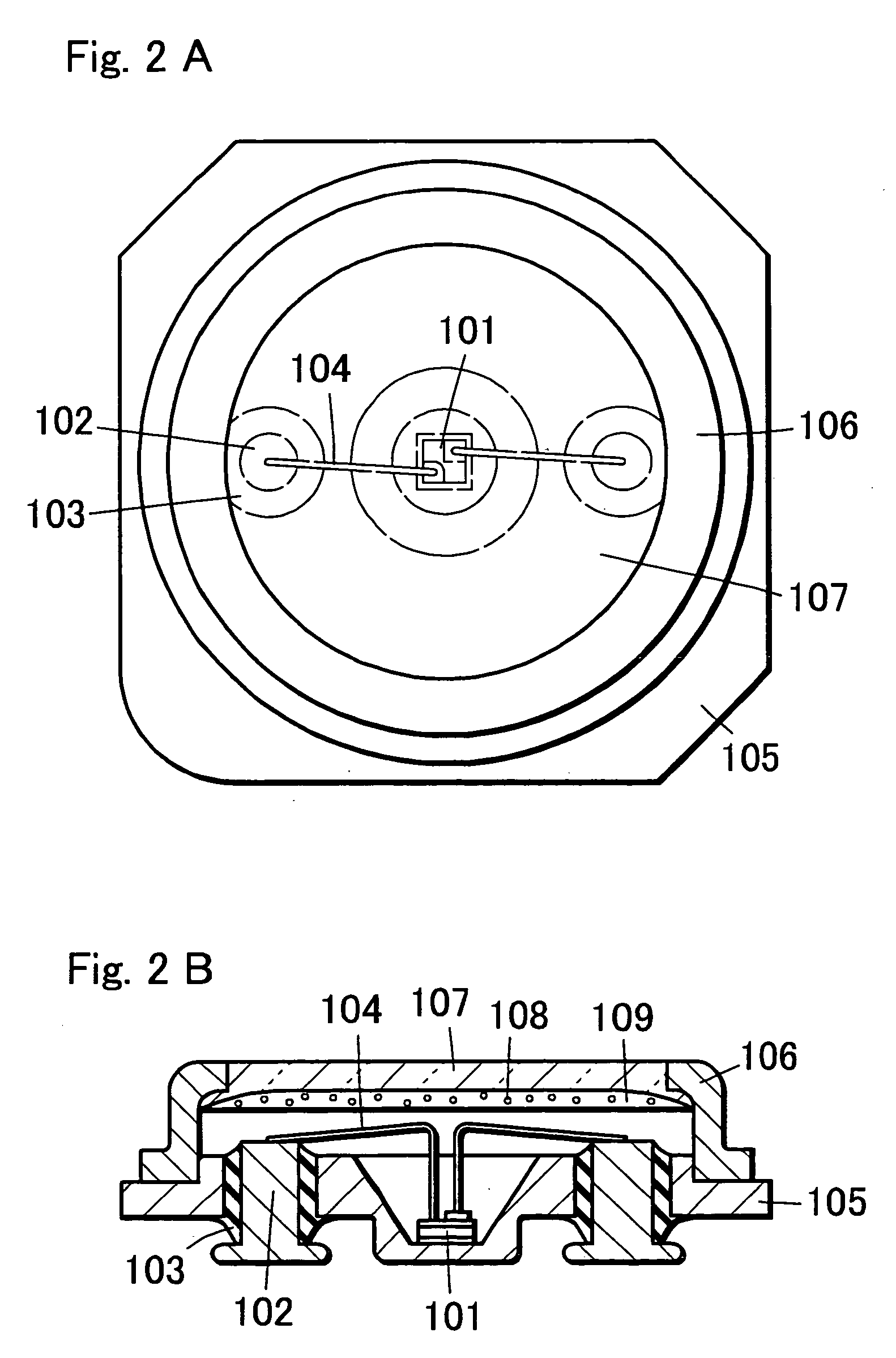

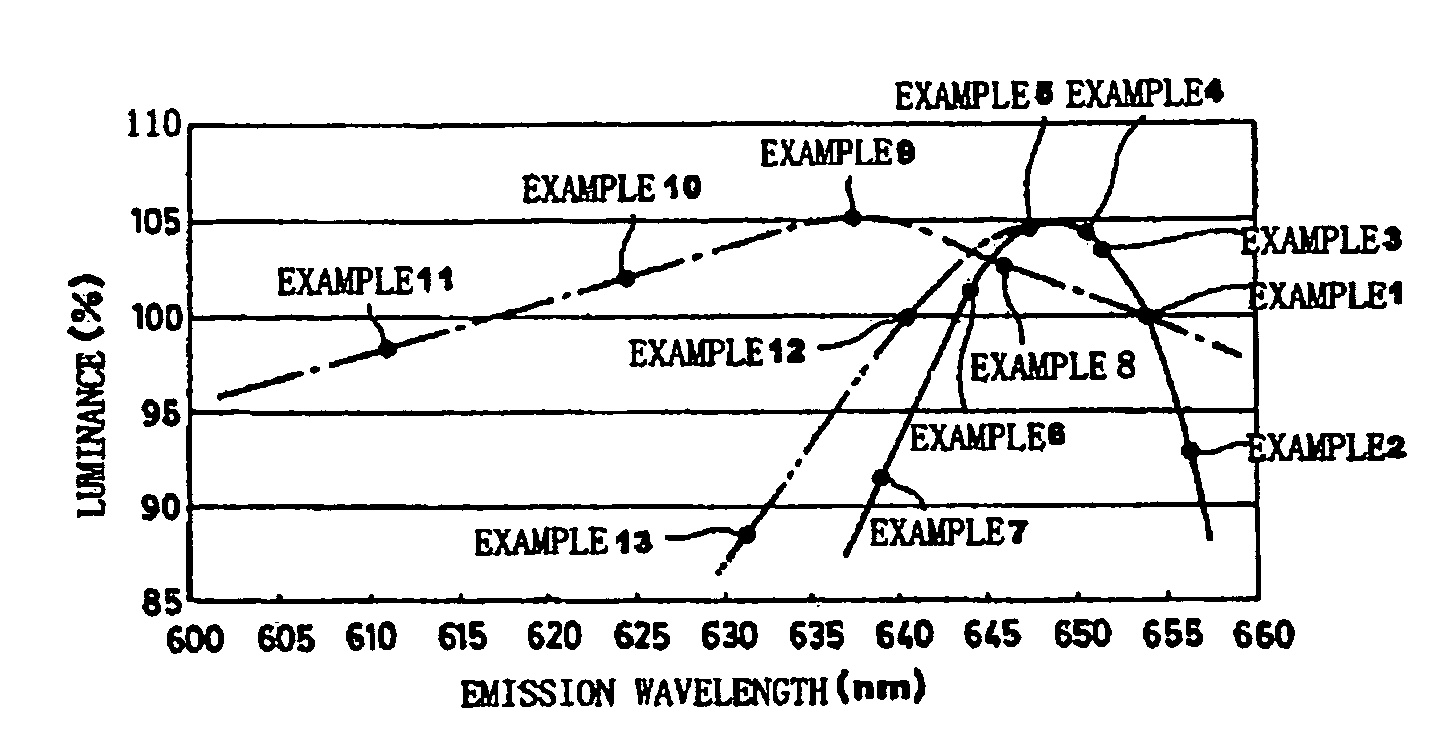

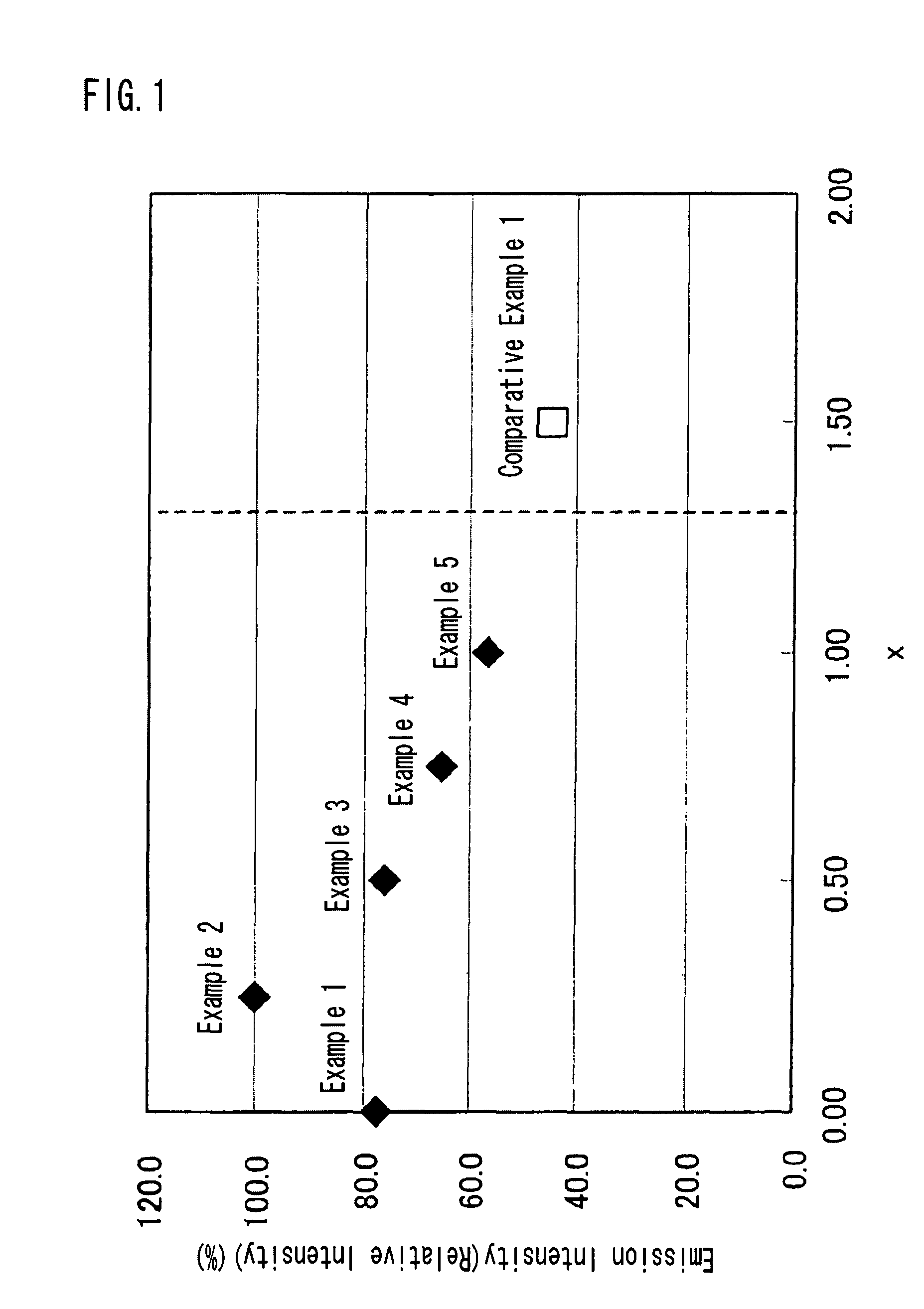

Phosphor and production method of the same, method of shifting emission wavelength of phosphor, and light source and LED

ActiveUS7273568B2High sensitivityImprove luminous performanceDischarge tube luminescnet screensLamp detailsOxygenEuropium

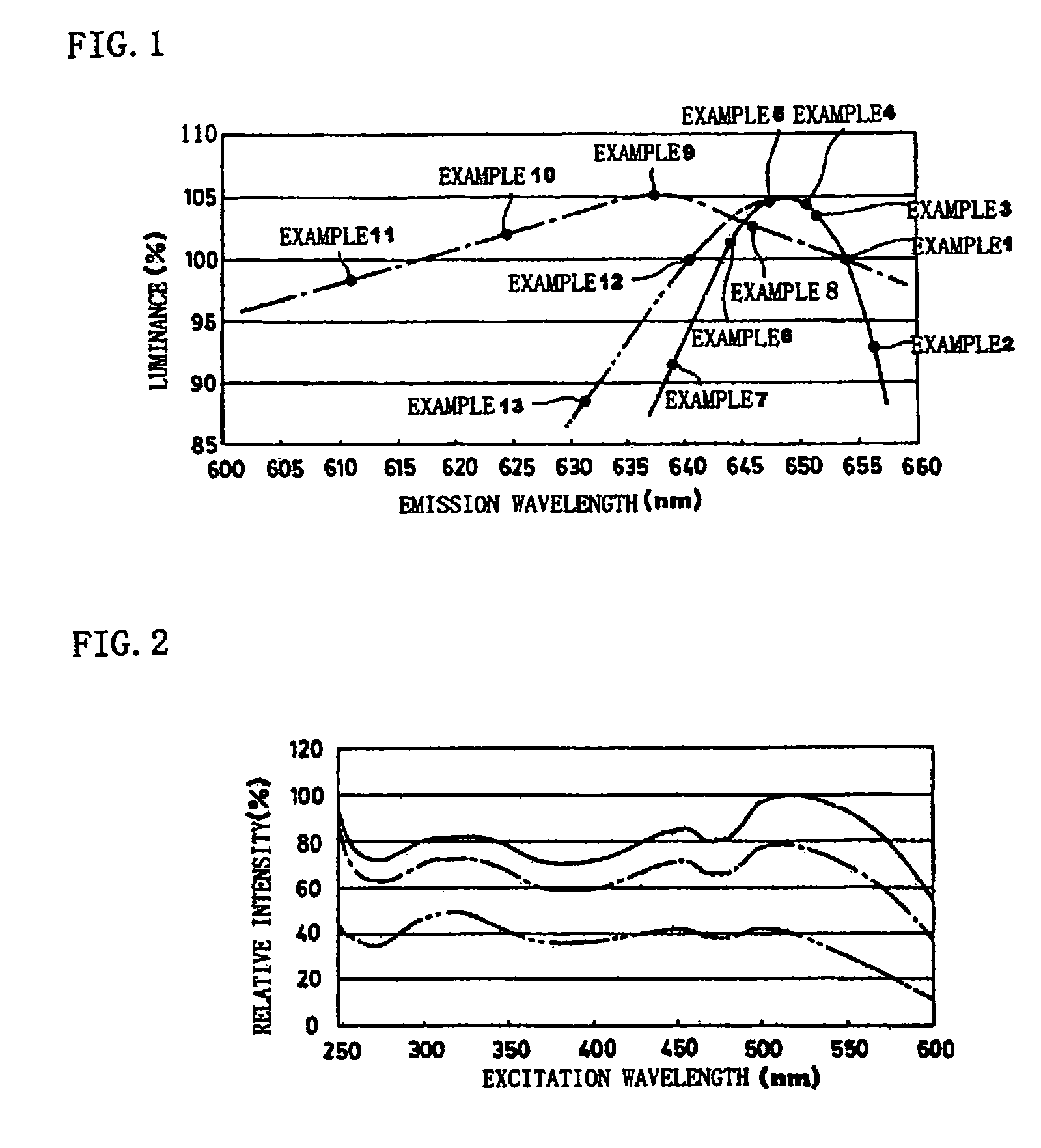

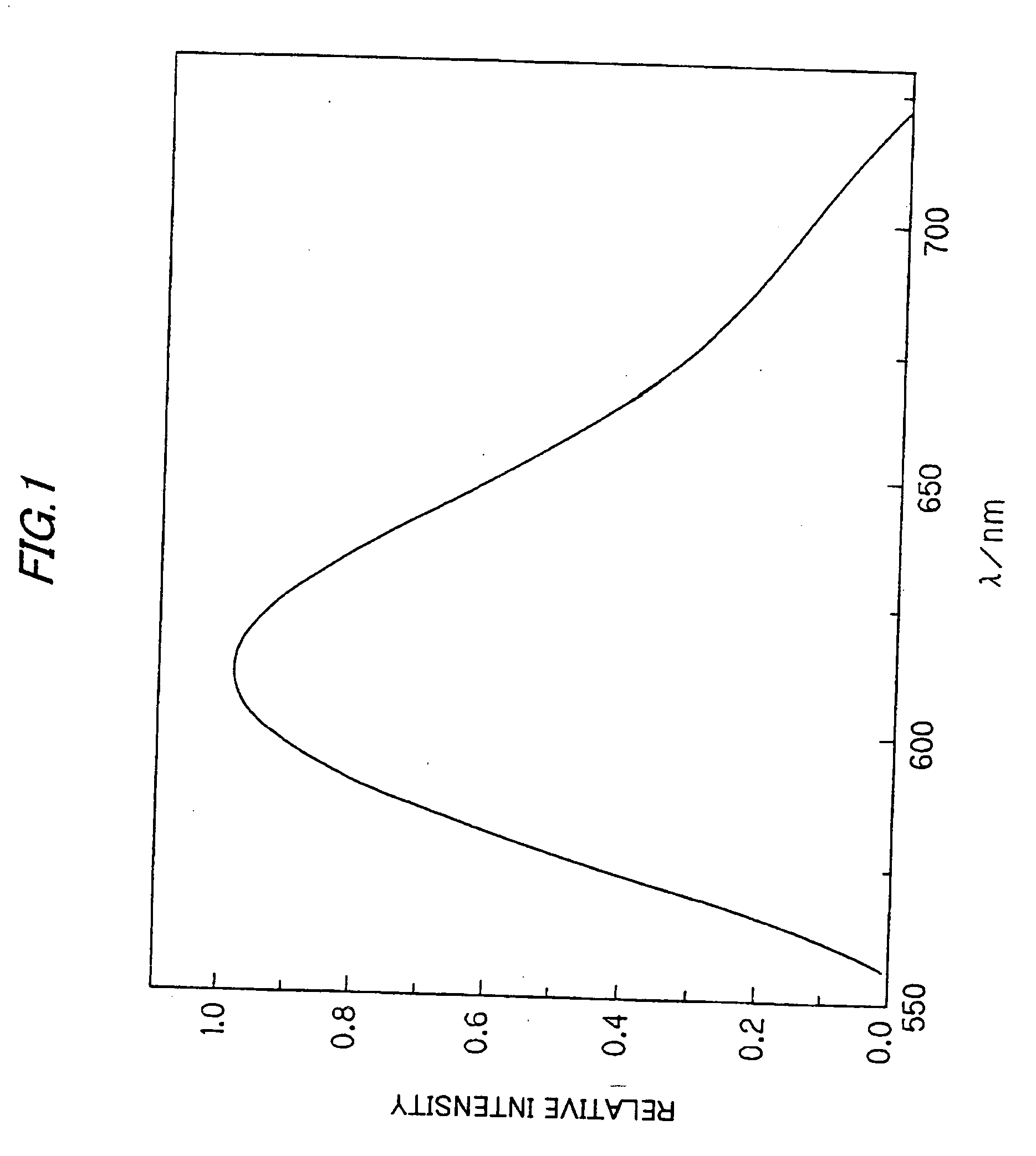

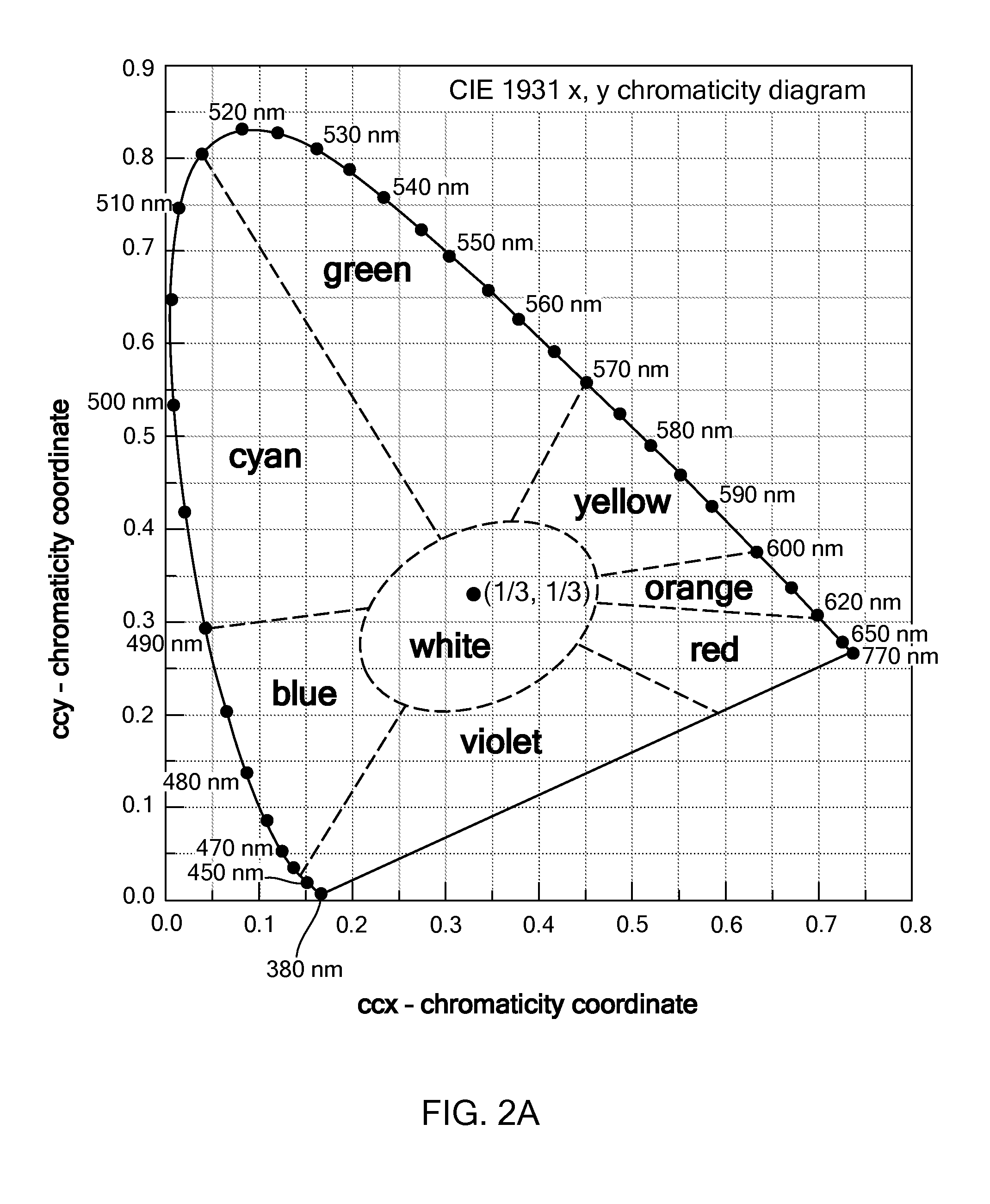

A phosphor including a main production phase of a phosphor expressed by a composition formula of MmAaBbOoNn:Zz (where an element M is one or more bivalent elements, an element A is one or more trivalent elements, an element B is one or more tetravalent elements, O is oxygen, N is nitrogen, an element Z is an activator, n=2 / 3m+a+4 / 3b−2 / 3o, m / (a+b)≧1 / 2, (o+n) / (a+b)>4 / 3, wherein m=a=b=1 and o and n is not 0). A phosphor including 24 wt % to 30 wt % of Ca (calcium), 17 wt % to 21 wt % of Al (aluminum), 18 wt % to 22 wt % of Si (silicon), 1 wt % to 15 wt % of oxygen, 15 wt % to 33 wt % of nitrogen and 0.01 wt % to 10 wt % of Eu (europium), wherein an emission maximum in an emission spectrum is in a range of 600 nm to 660 nm; and wherein color chromaticity x of light emission is in a range of 0.5 to 0.7, and color chromaticity y of the light emission is in a range of 0.3 to 0.5.

Owner:NICHIA CORP

Phosphor and Manufacturing Method Therefore, and Light Emission Device Using the Phosphor

InactiveUS20090267485A1Improve emission characteristicsBroad emission spectrumDischarge tube luminescnet screensSemiconductor/solid-state device detailsUltravioletOxygen

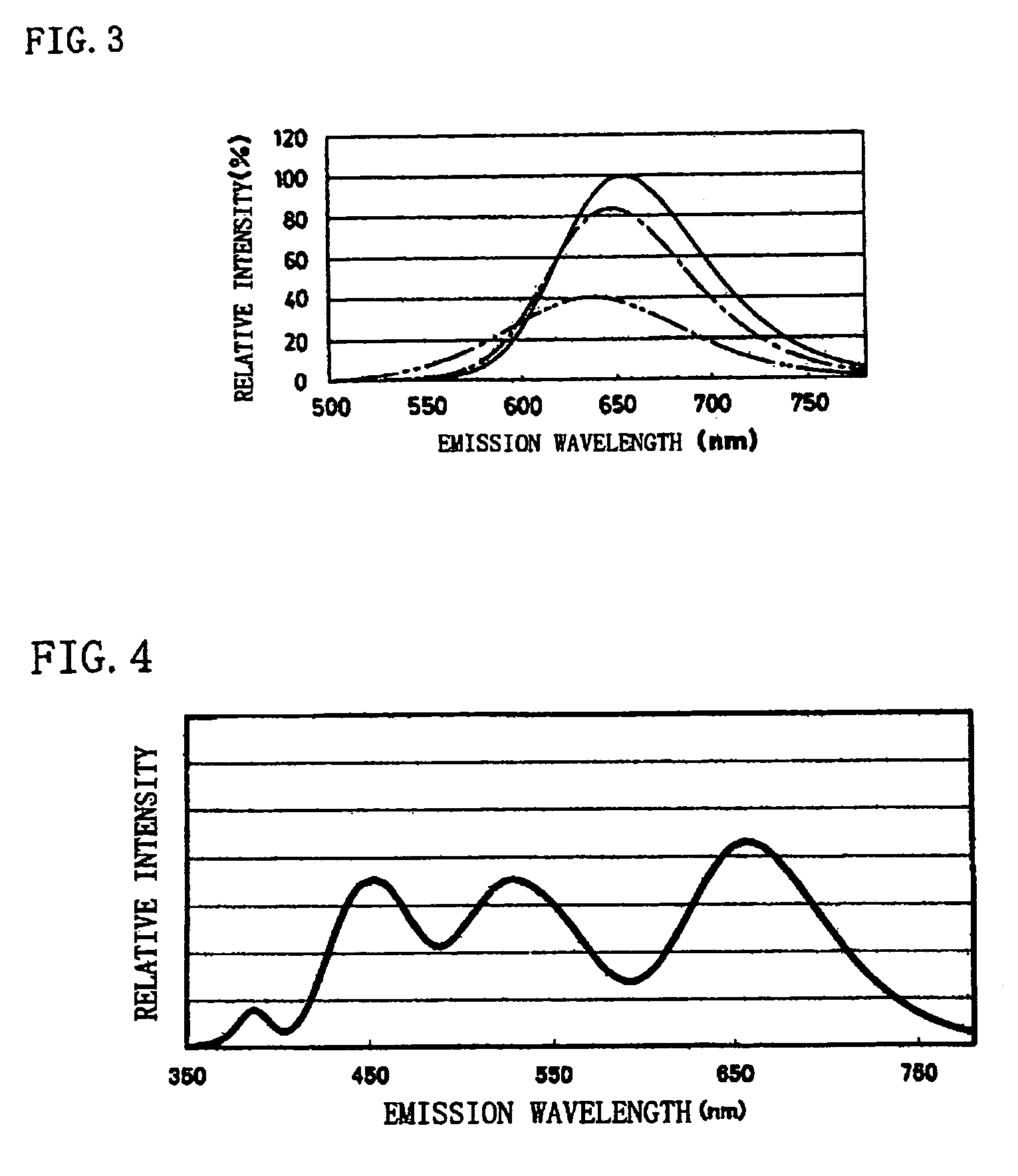

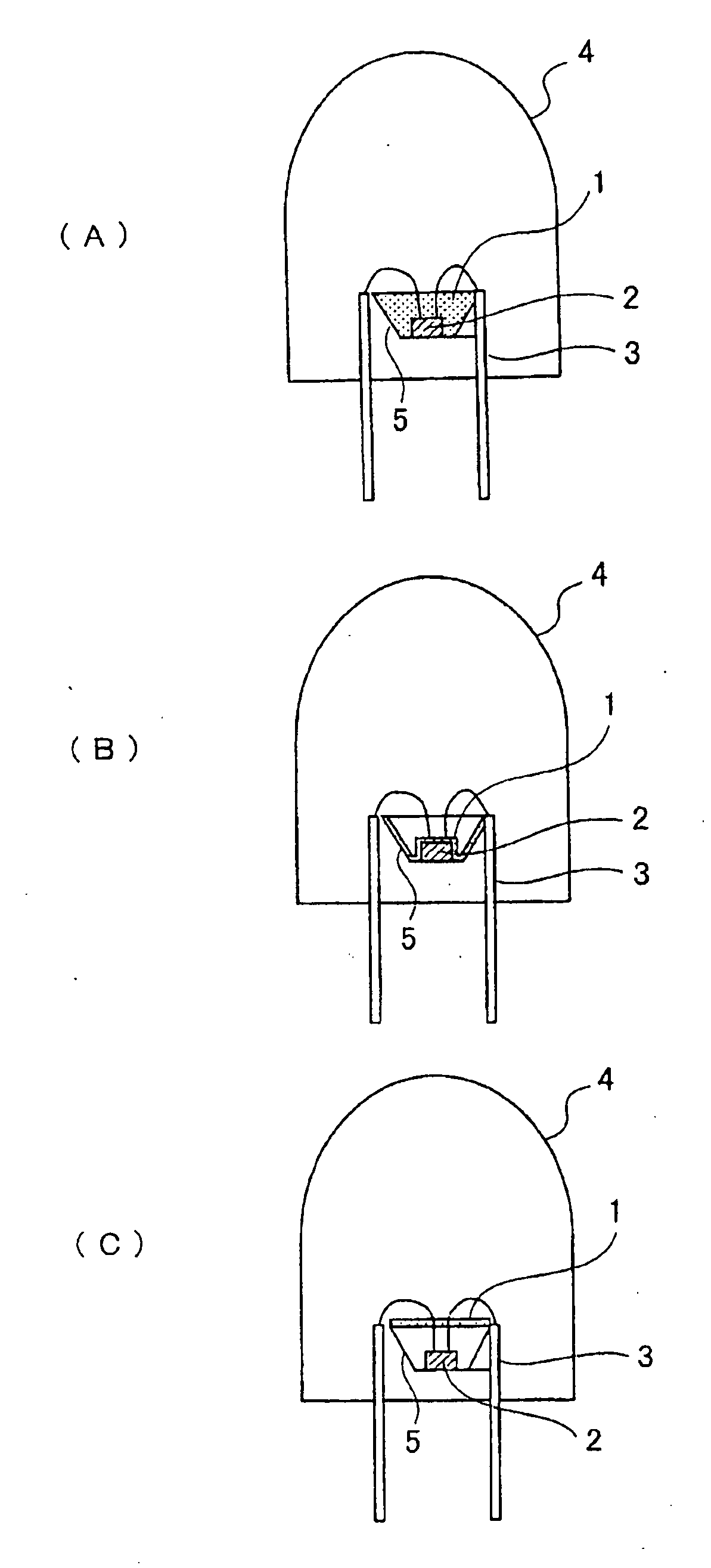

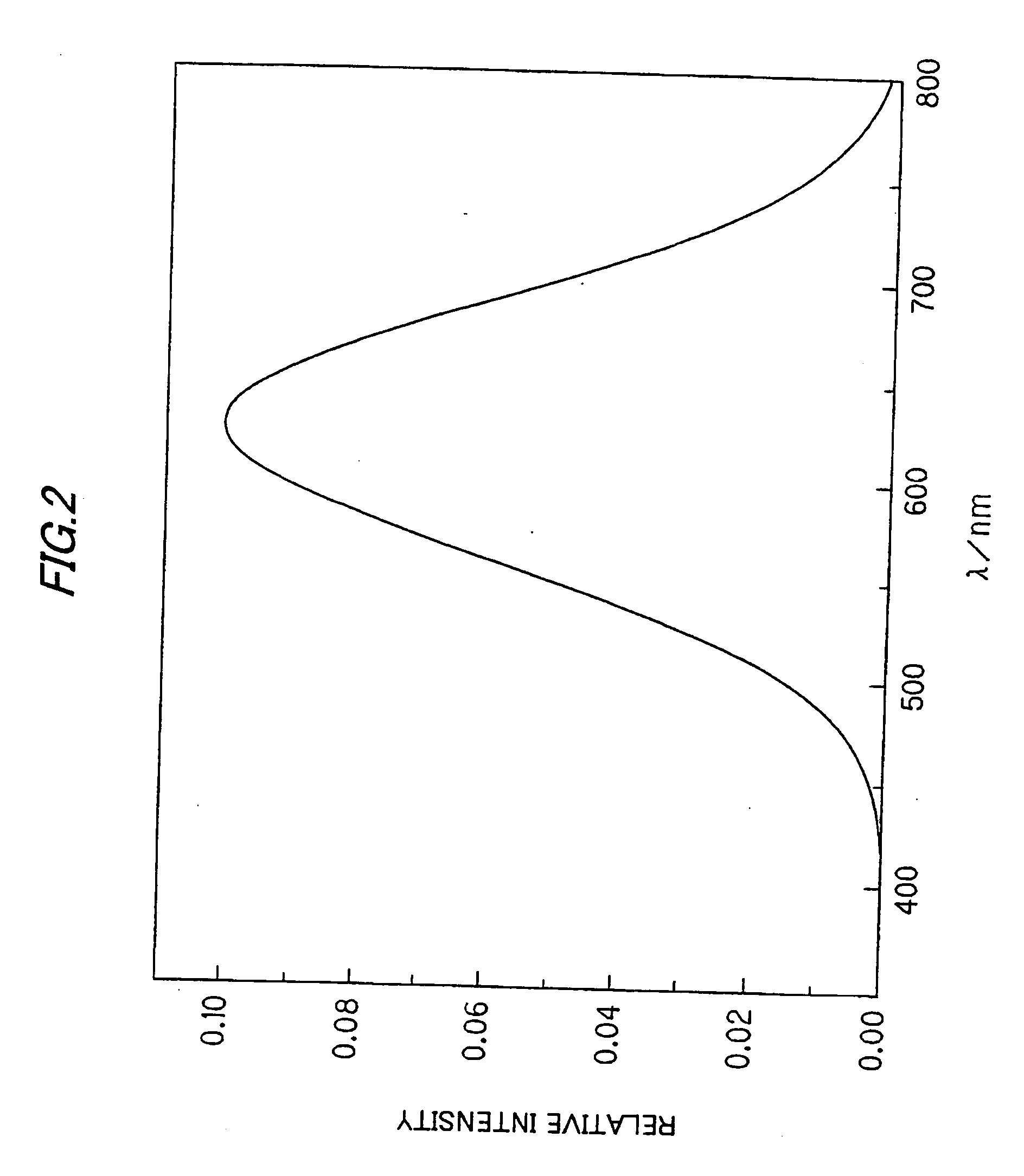

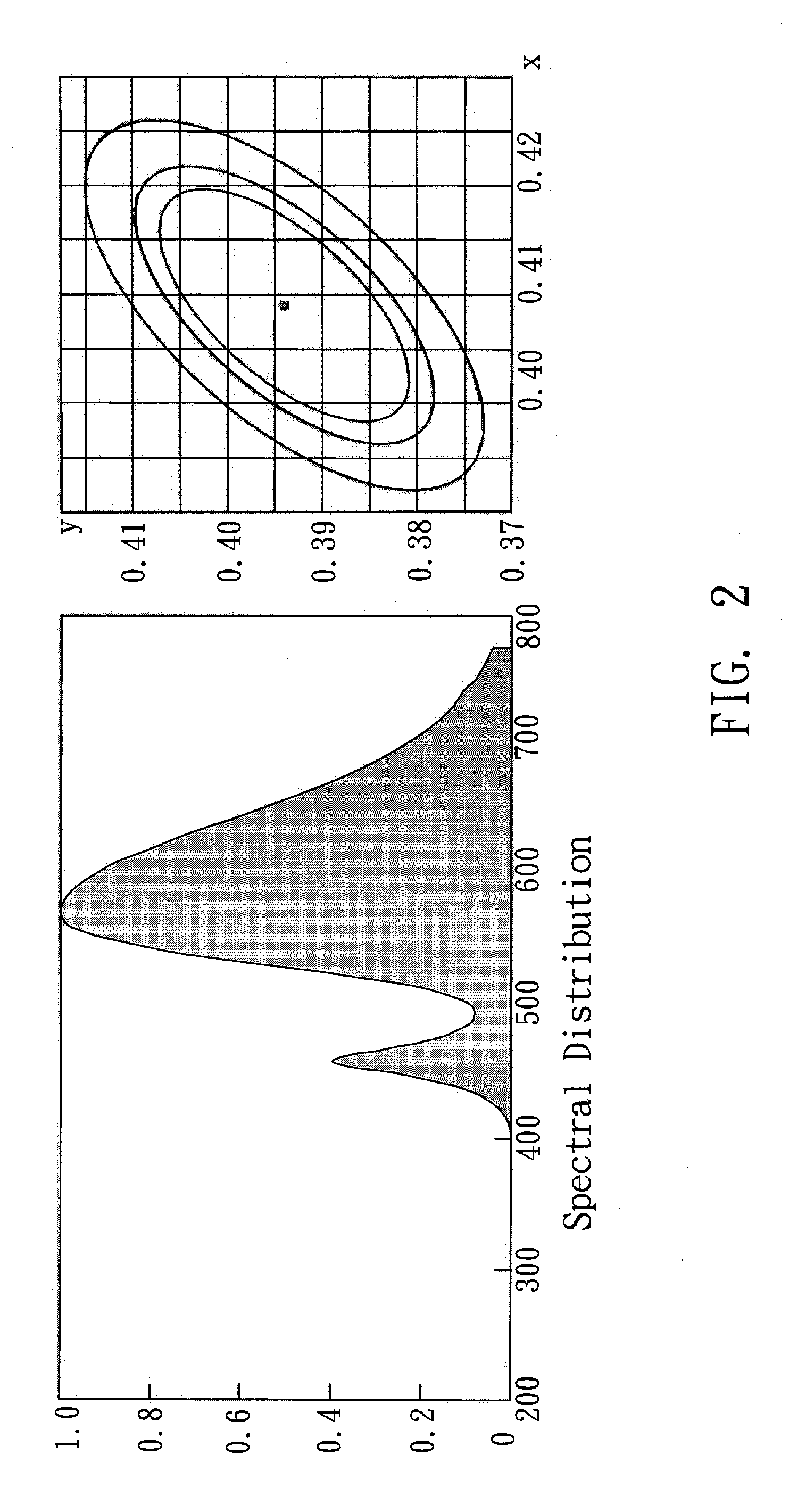

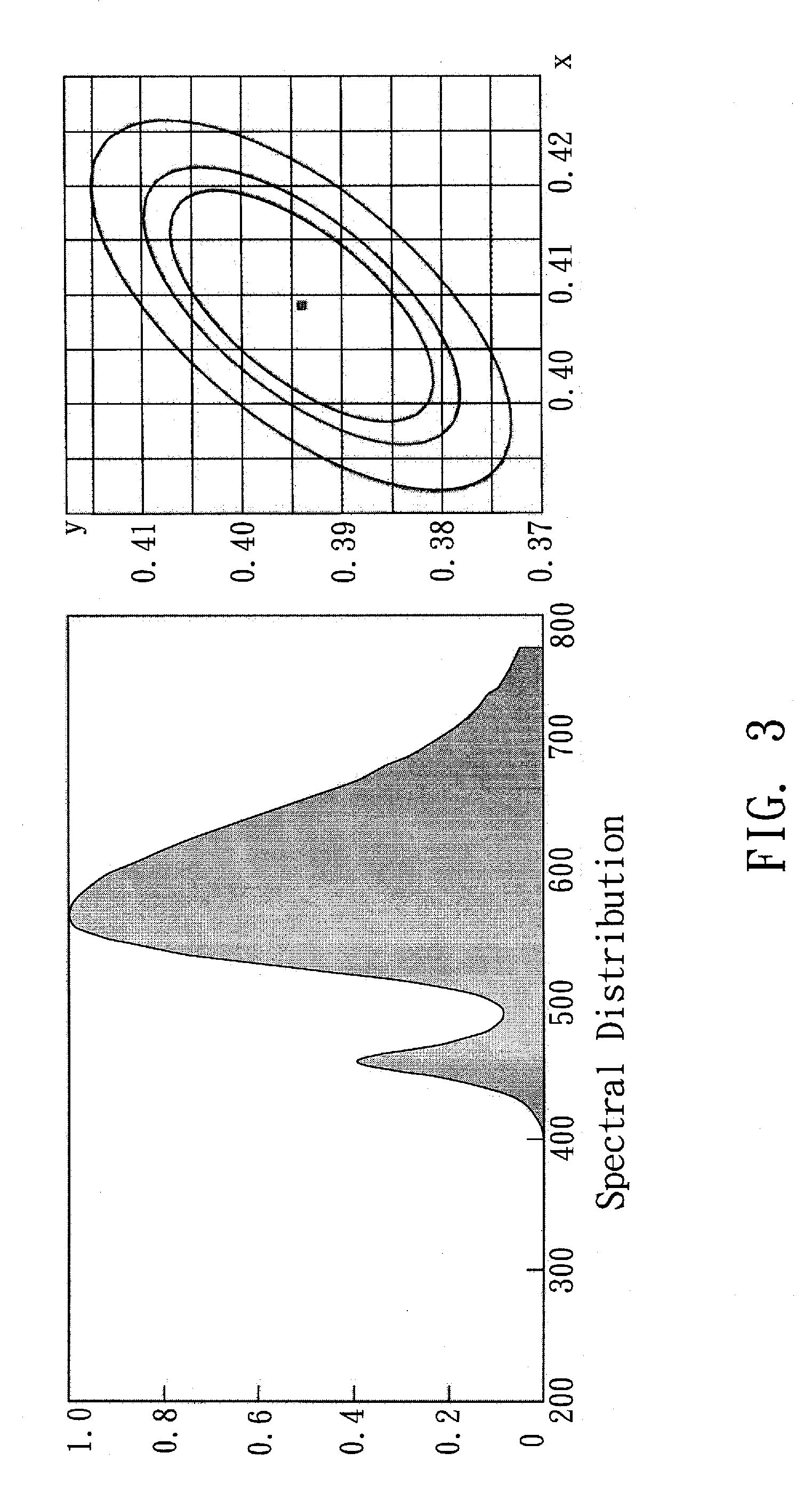

To provide a phosphor for manufacturing an one chip type LED illumination, etc, by combining a near ultraviolet / ultraviolet LED and a blue LED, and having an excellent emission efficiency including luminance. The phosphor is given as a general composition formula expressed by MmAaBbOoNn:Z, (where element M is one or more kinds of elements having bivalent valency, element A is one or more kinds of elements having tervalent valency, element B is one or more kinds of elements having tetravalent valency, O is oxygen, N is nitrogen, and element Z is one or more kinds of elements acting as an activator.), satisfying a=(1+x)×m, b=(4−x)×m, o=x×m, n=(7−x)×m, 0≦x≦1, wherein when excited by light in a wavelength range from 300 nm to 500 nm, the phosphor has an emission spectrum with a peak wavelength in a range from 500 nm to 620 nm.

Owner:MITSUBISHI CHEM CORP

Oxonitride phosphor and method for production thereof, and luminescent device using the oxonitride phosphor

ActiveCN1705732AImprove luminous brightnessImprove featuresSolid-state devicesNitrogen and non-metal compoundsPhosphorRare earth

An oxonitride phosphor which comprises a crystal containing at least one Group II element selected from the group consisting of Be, Mg, Ca, Sr, Ba and Zn, at least one Group IV element selected from the group consisting of C, Si, Ge, Sn, Ti, Zr and Hf, and a rare earth metal as an activator R. The oxonitride phosphor is exited by an excitation light source of an ultraviolet to visible region and emits a light having a color of from a blue-green region to a yellow region.

Owner:NICHIA CORP

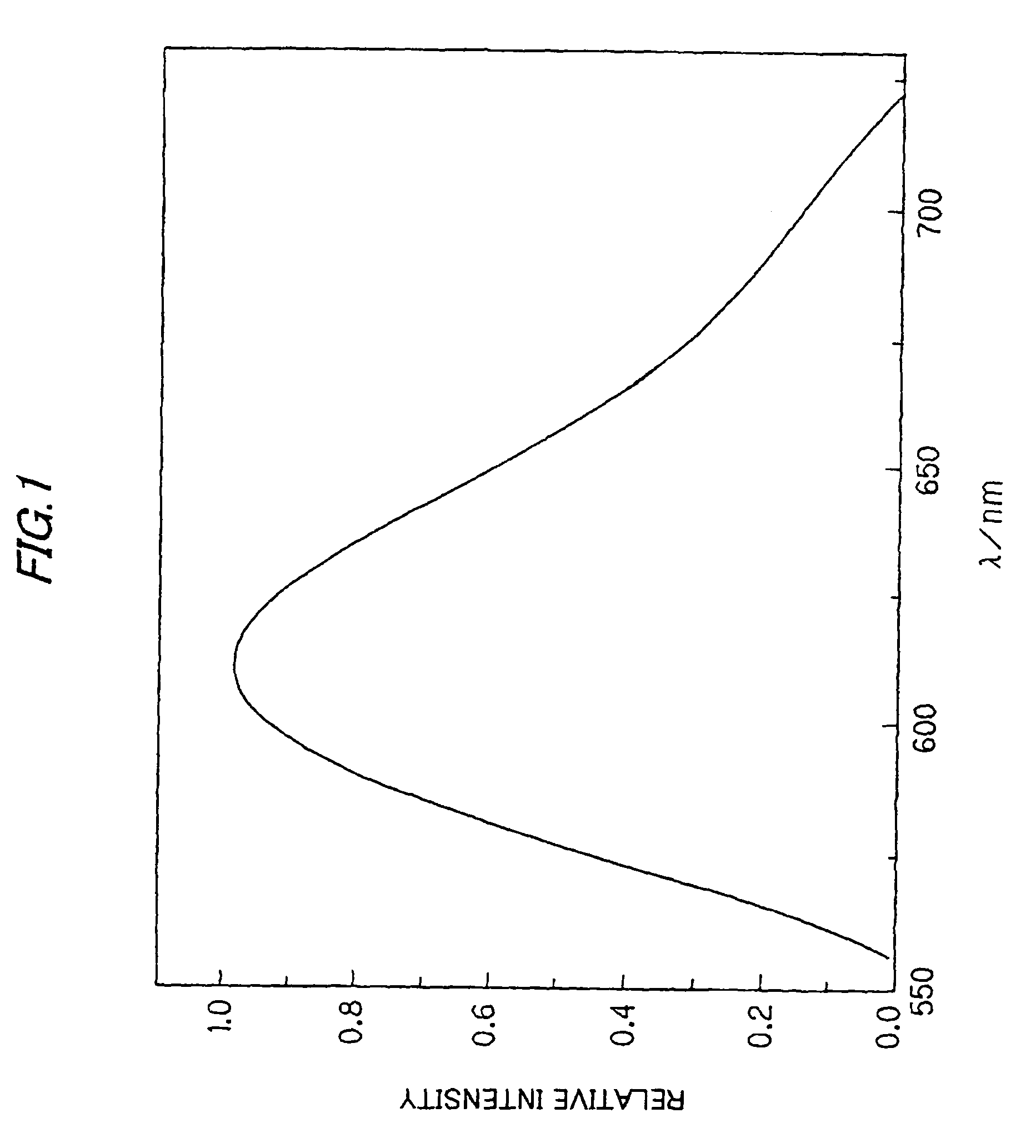

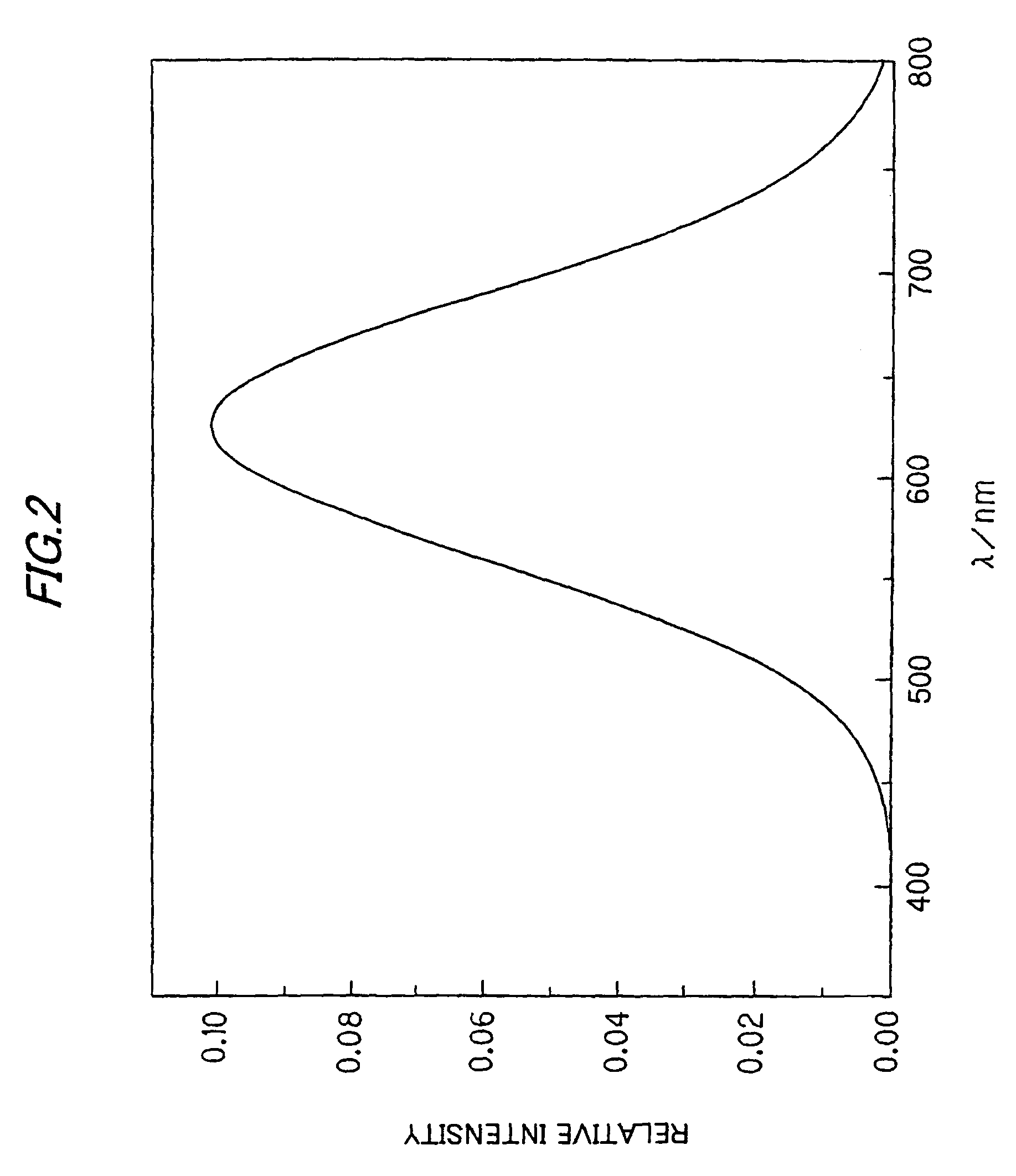

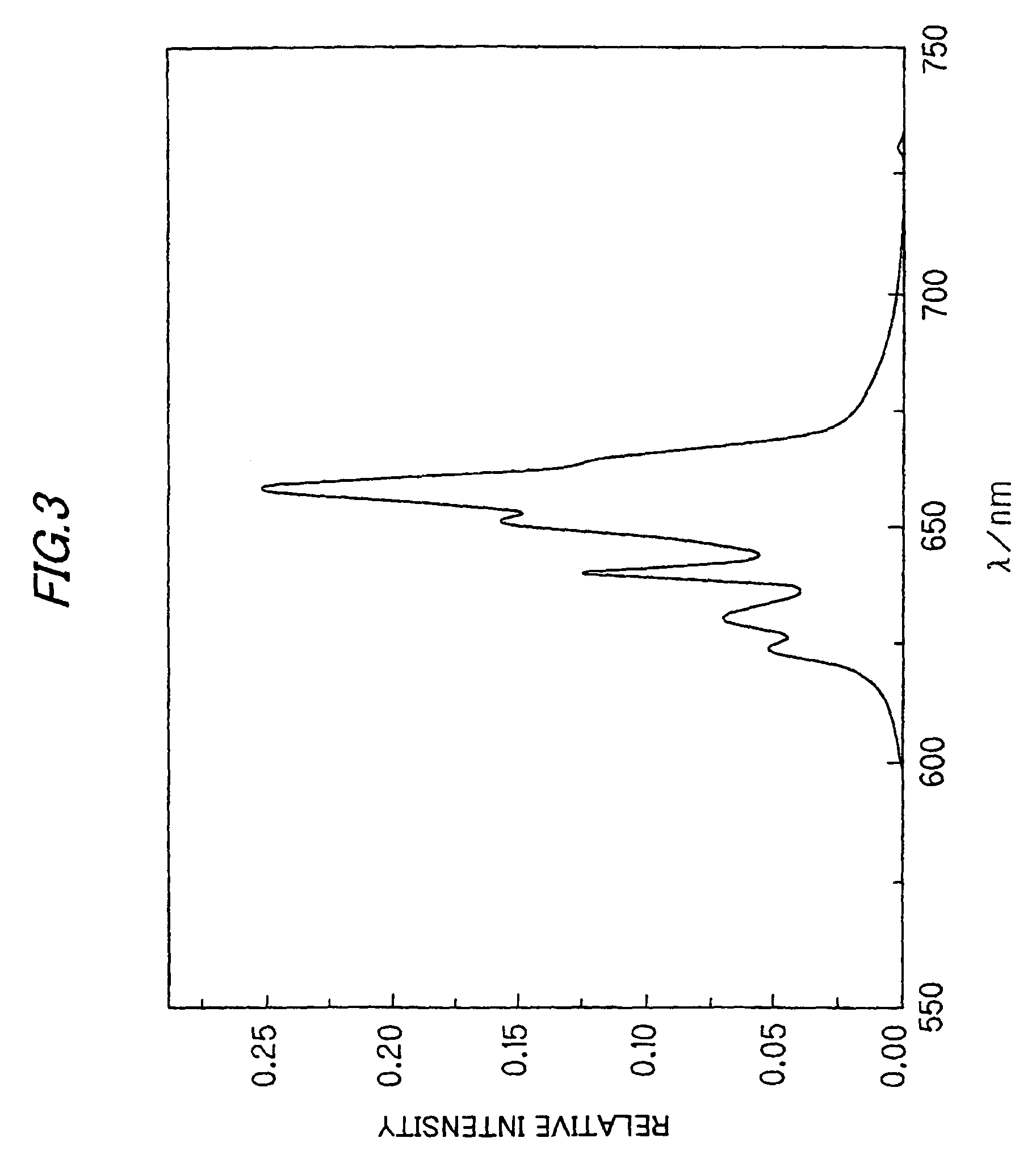

Phosphor and optical device using same

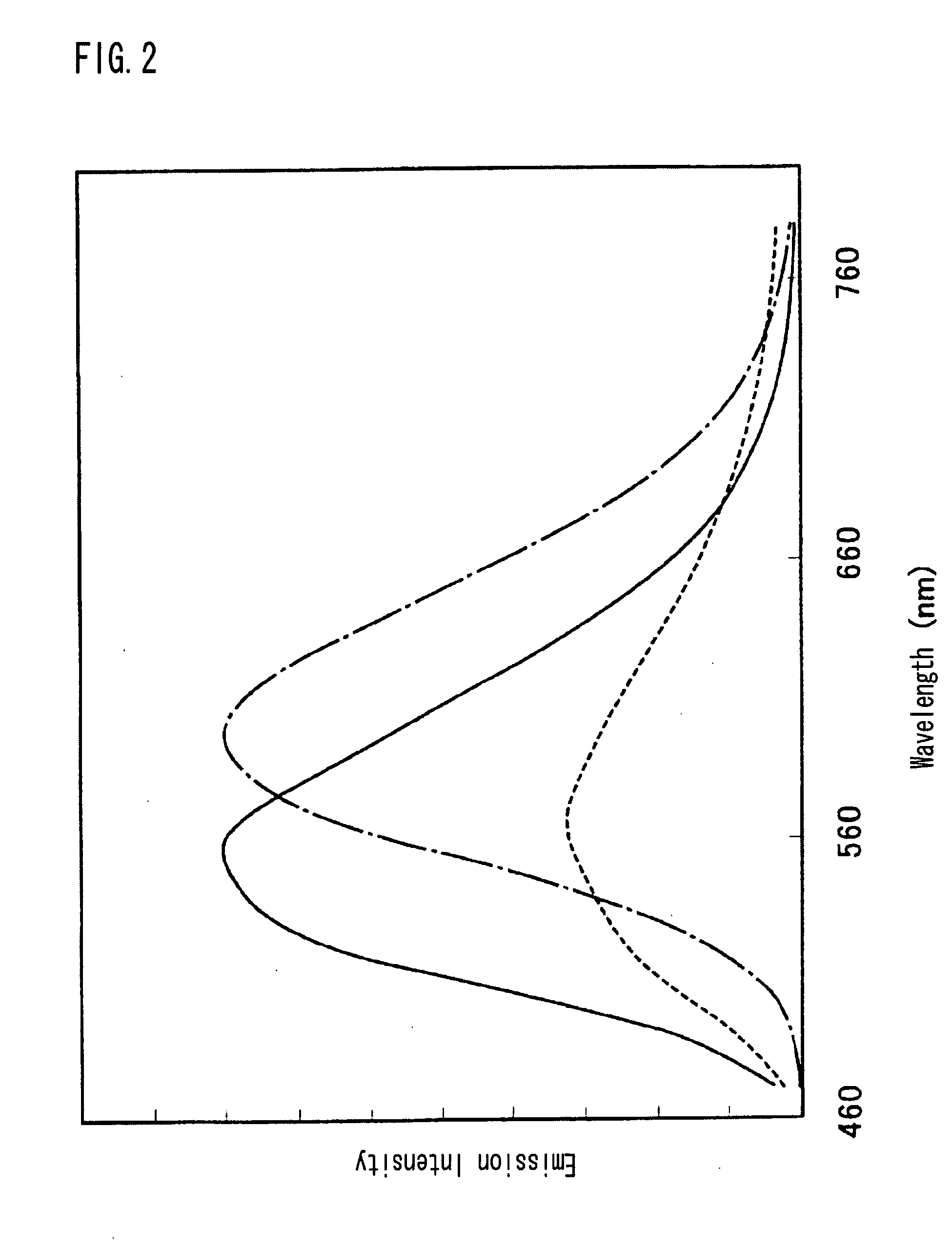

InactiveUS20070035813A1Good colorSolid-state devicesEnergy efficient lightingAlkaline earth metalColored white

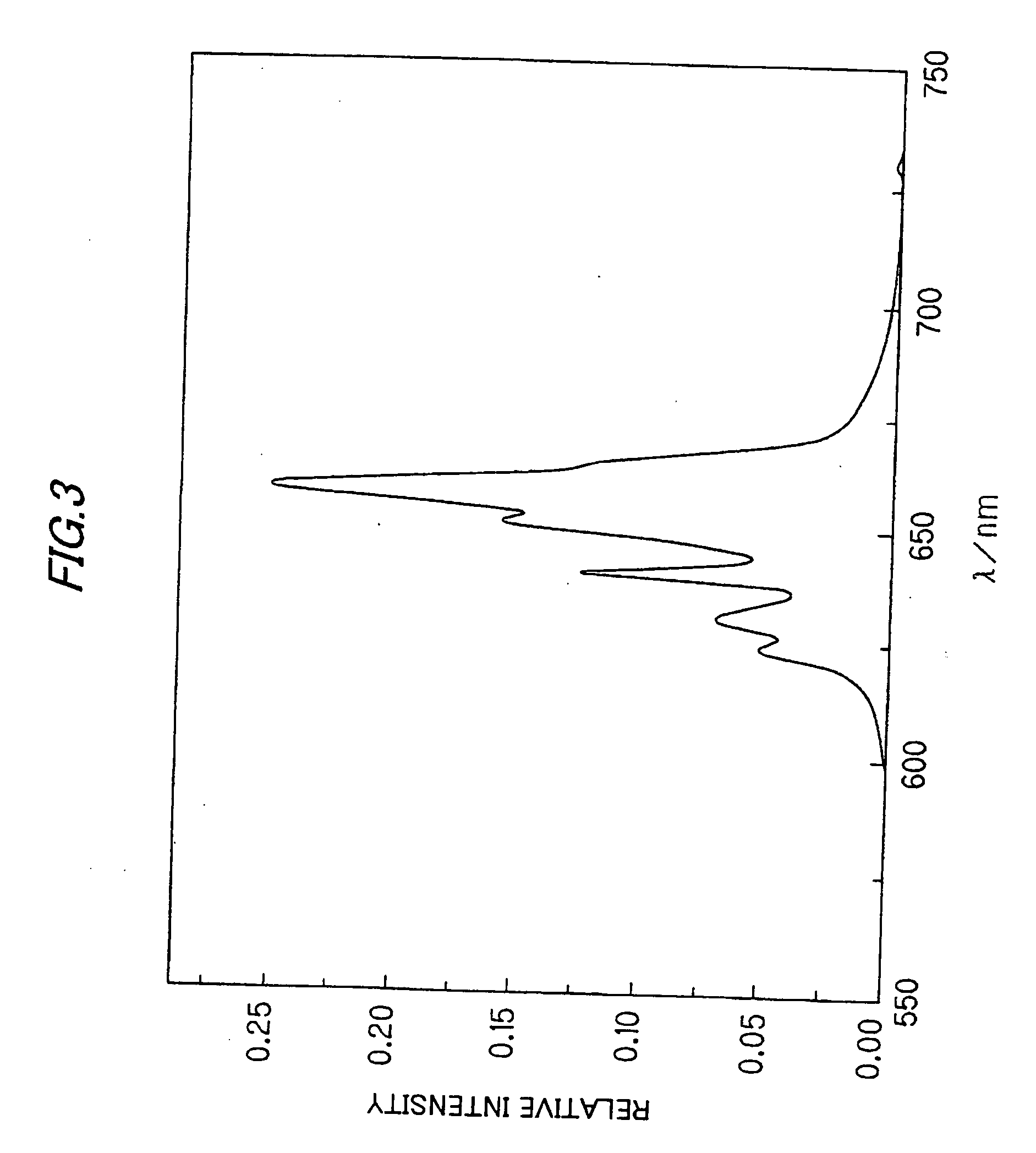

A phosphor for converting ultraviolet light or blue light emitted from a light emitting element into a visible white radiation having a high level of color rendering properties, containing a light emitting component prepared from a solid system of an alkaline earth metal antimonate and a system derived from the solid system and exhibiting intrinsic photoemission, such as a fluoroantimonate, a light emitting component prepared from a manganese(IV)-activated antimonate, a titanate, silicate-germanate, and an aluminate, a light emitting component prepared from a europium-activated silicate-germanate or from a system containing a sensitizer selected from a group consisting of europium (II) and manganese (II) as a secondary activator and having an orange color or a dark red color in the spectrum range over 600 nm, or a light emitting component composed of a mixture of eight or less light emitting components having different emission bands and brought to a state of continuous emission of about 380 to 780 nm exhibiting a color temperature of about 10,000 to 6,500 K and a color temperature of about 3,000 to 2,000 K by virtue of the superposition of the light emitting bands.

Owner:TOYODA GOSEI CO LTD +2

Scintillator plate for radiation and production method of the same

InactiveUS20070108393A1Improve emission efficiencyPhotometryFluorescence/phosphorescencePhosphorFluorescence

A scintillator plate for radiation comprising a substrate having thereon a phosphor layer comprising CsI and two or more activators ach having a melting point different from a melting point of CsI, wherein each content of the two or more activators is 0.01% or more based on CsI; and the scintillator plate is produced by forming the phosphor layer on the substrate via a vacum evaporation method using a source material comprising CsI and two or more activators.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

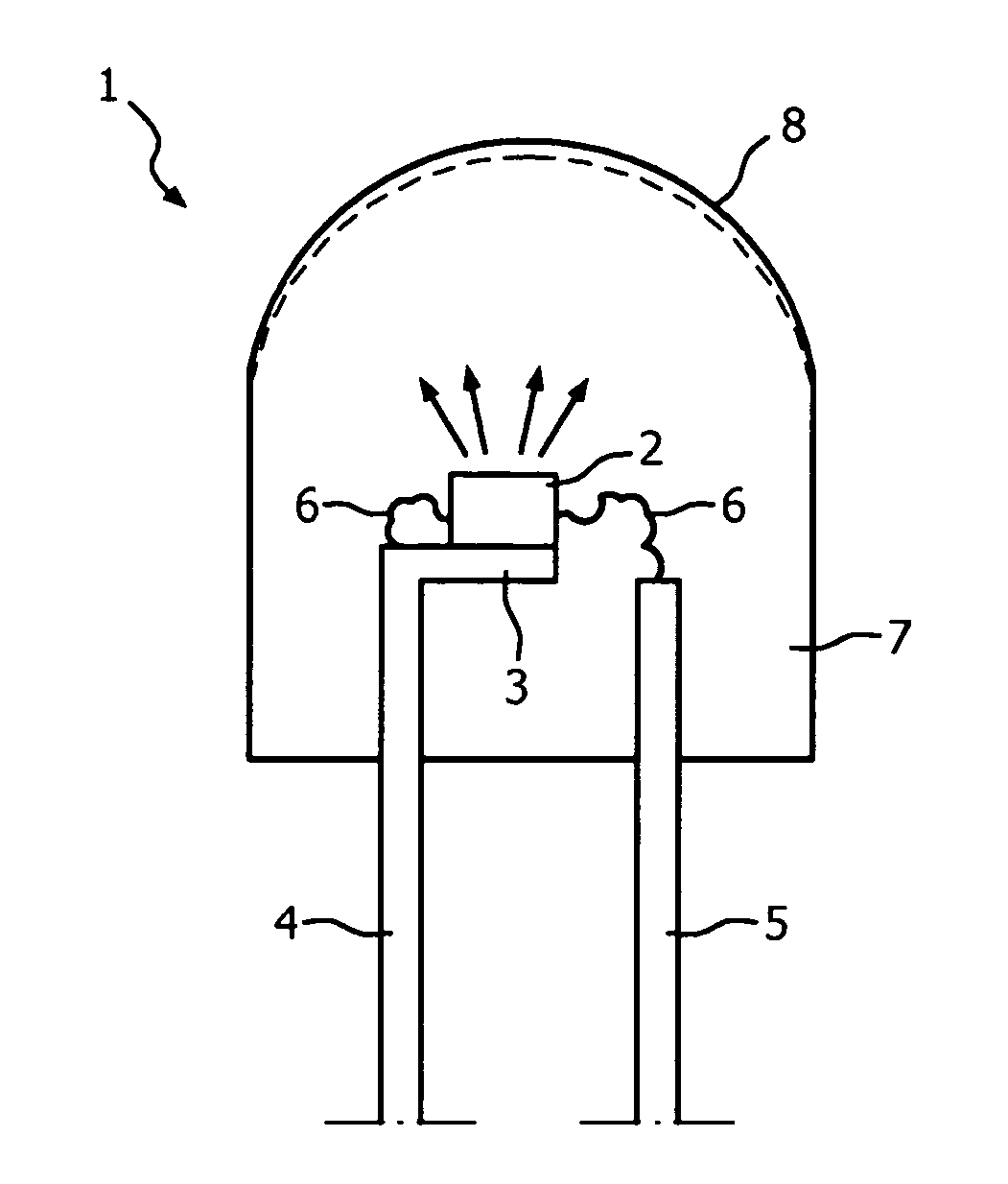

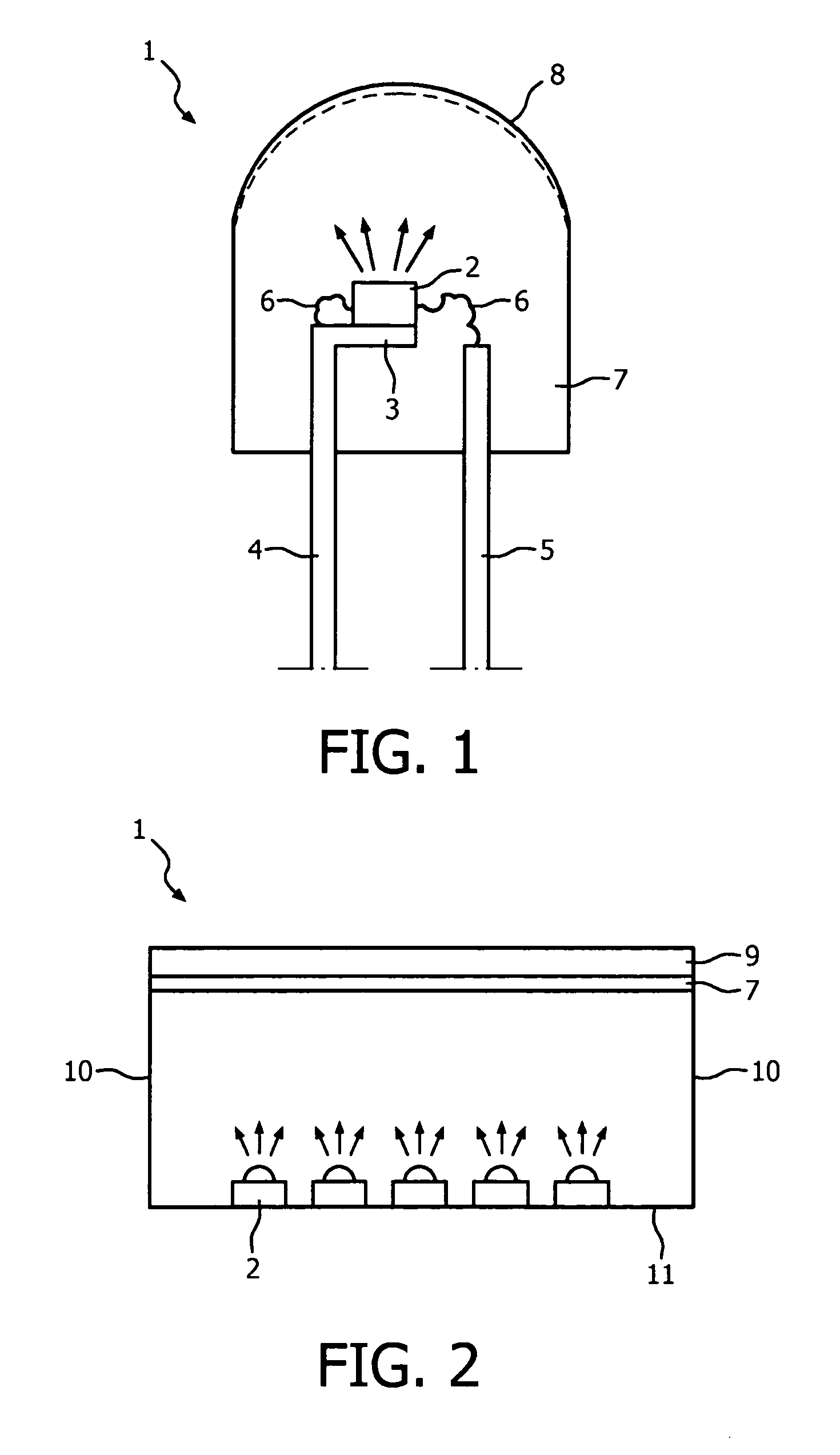

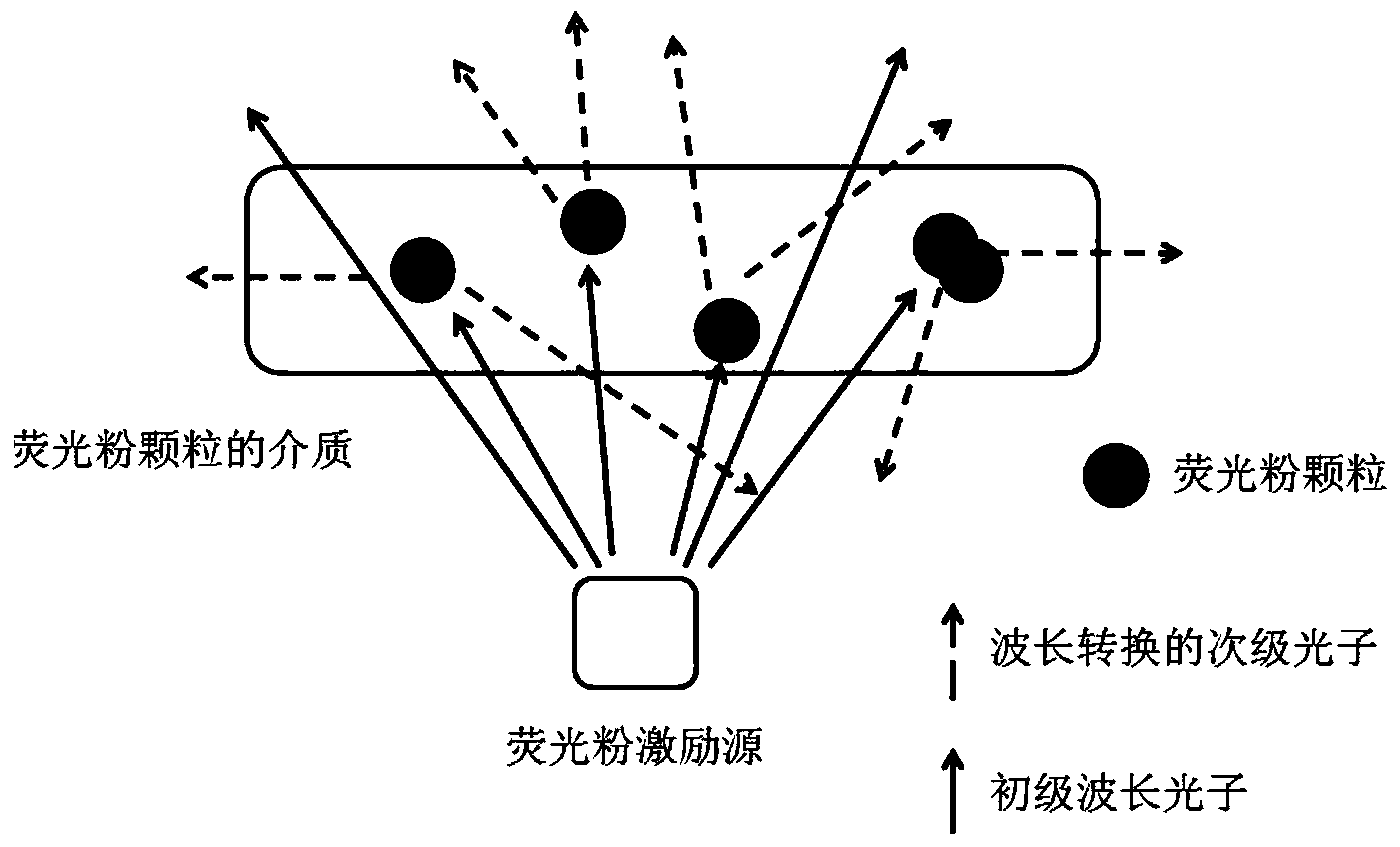

Lighting device with light source and wavelength converting element

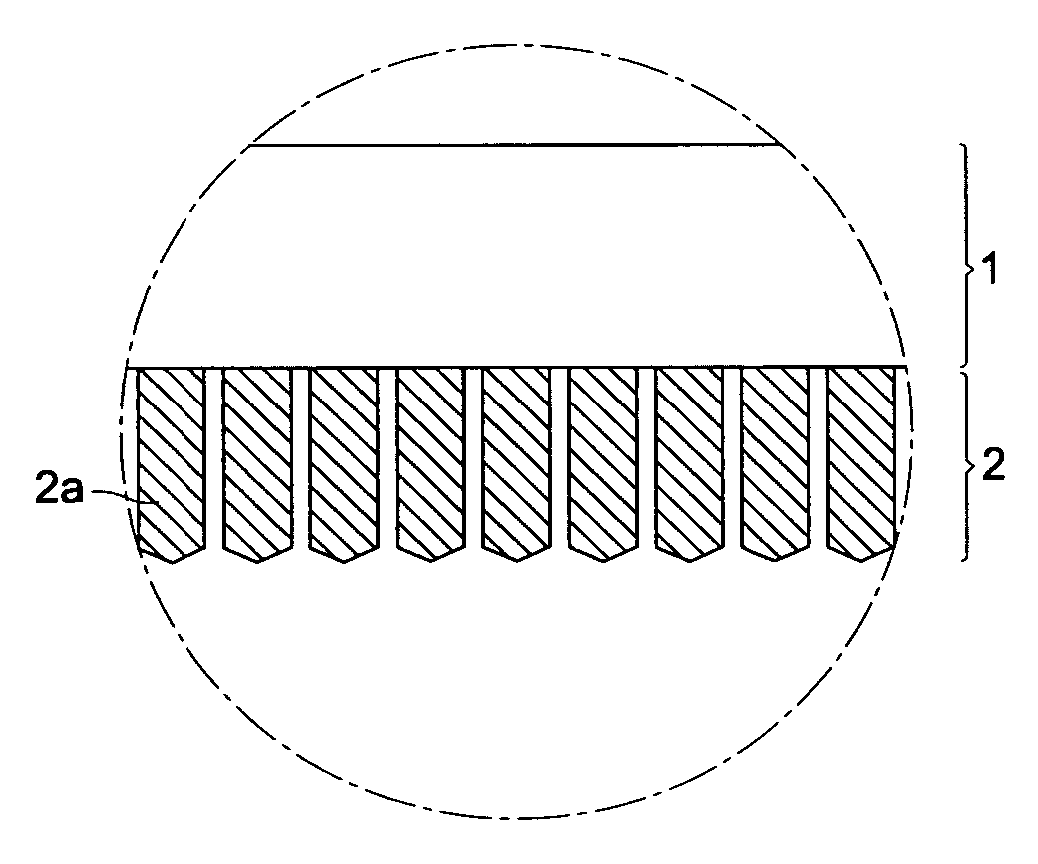

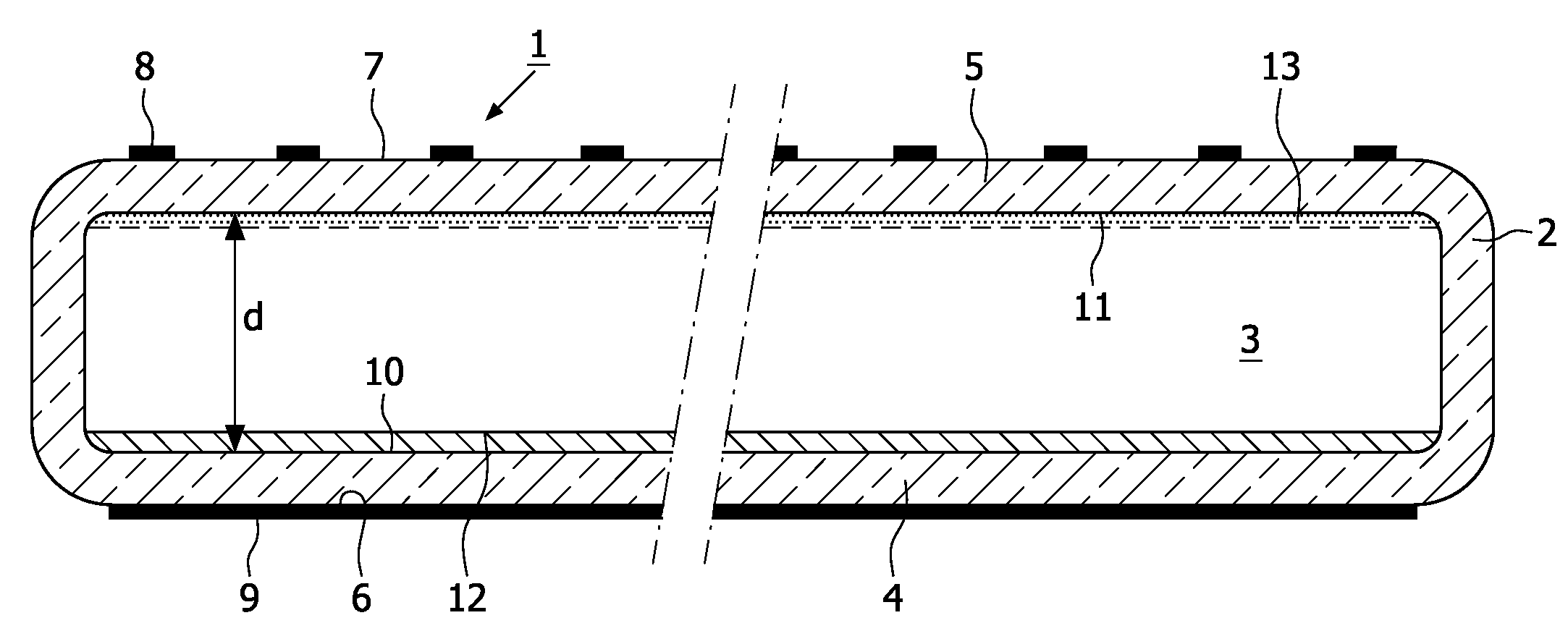

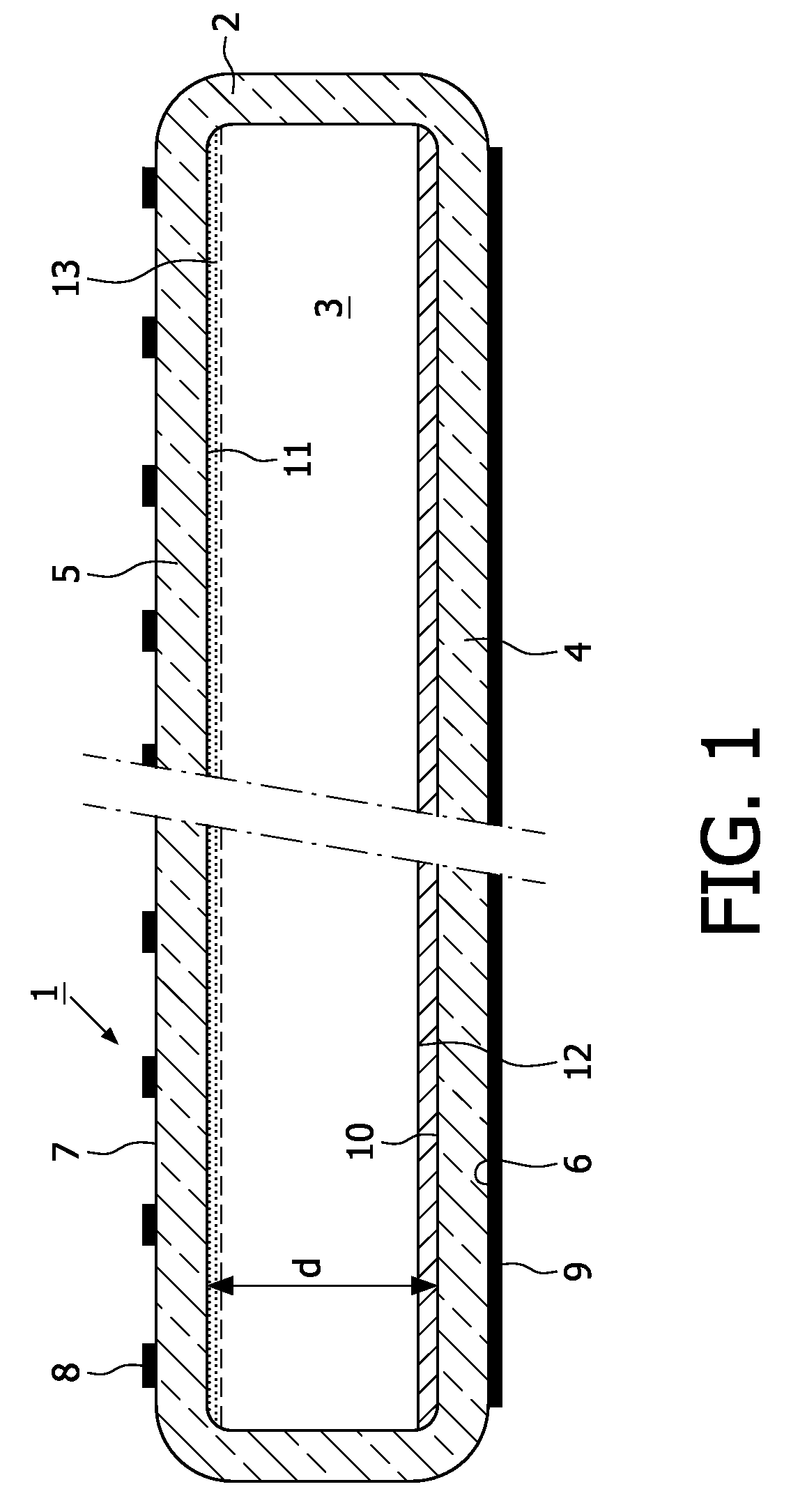

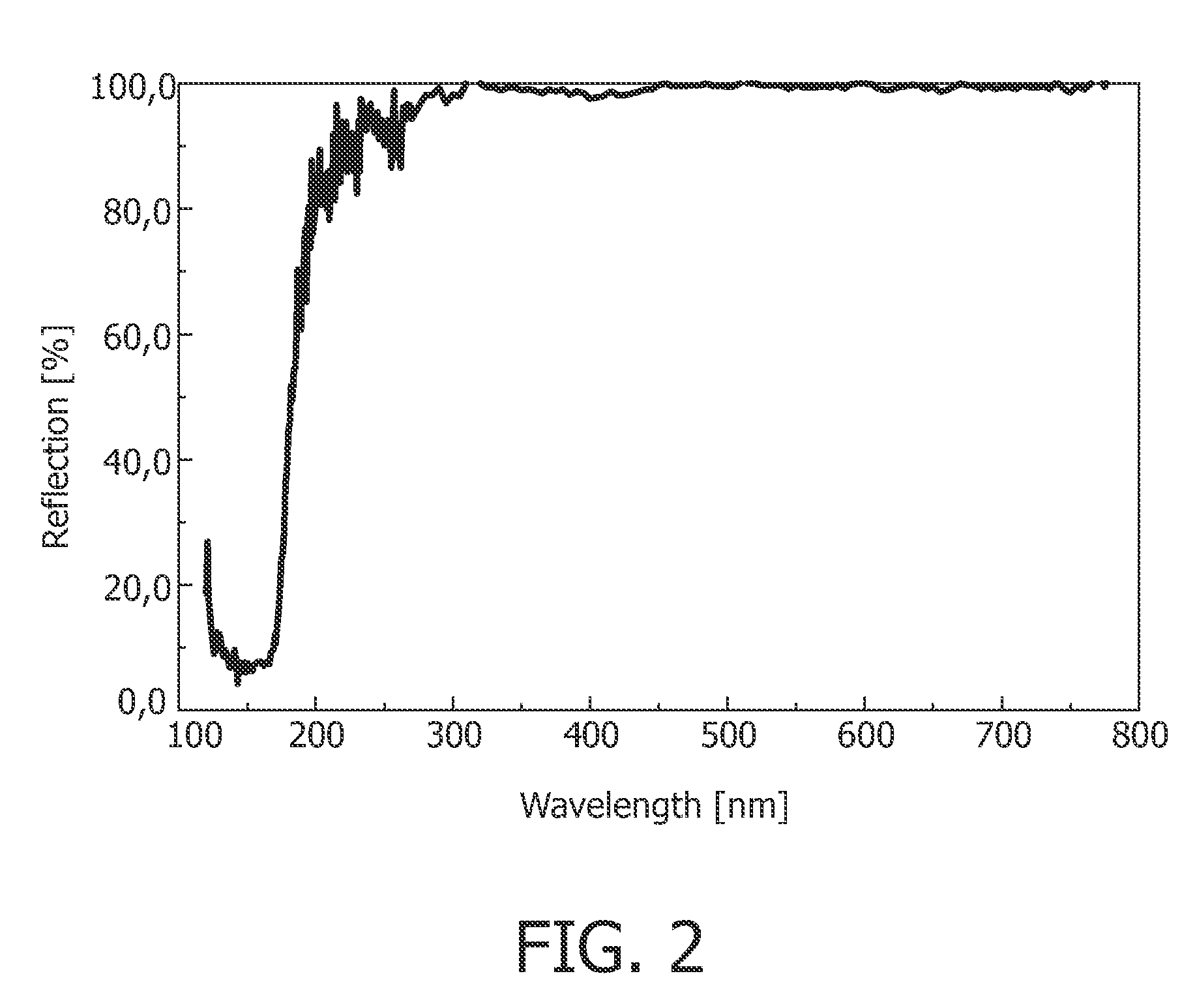

InactiveUS20120261704A1Reduce scatterSufficient conversion efficiencySolid-state devicesLight demodulationRefractive indexElectron

The invention relates to a lighting (1) device comprising a light source (2) and a wavelength converting element (7), which comprises a phosphor compounded with a polymer. The phosphor contains a metal-ion activator which is excitable via a partially forbidden electronic transition. The phosphor and the polymer being chosen such that the difference in their refractive index is smaller than 0.1. Due to this choice, scattering in the wavelength converting element (7) remains at minimum. Interesting wavelength converting elements (7) are obtained when using phosphors comprising specific Mn(IV)-activated fluoride compounds and specific fluorine-containing polymers.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

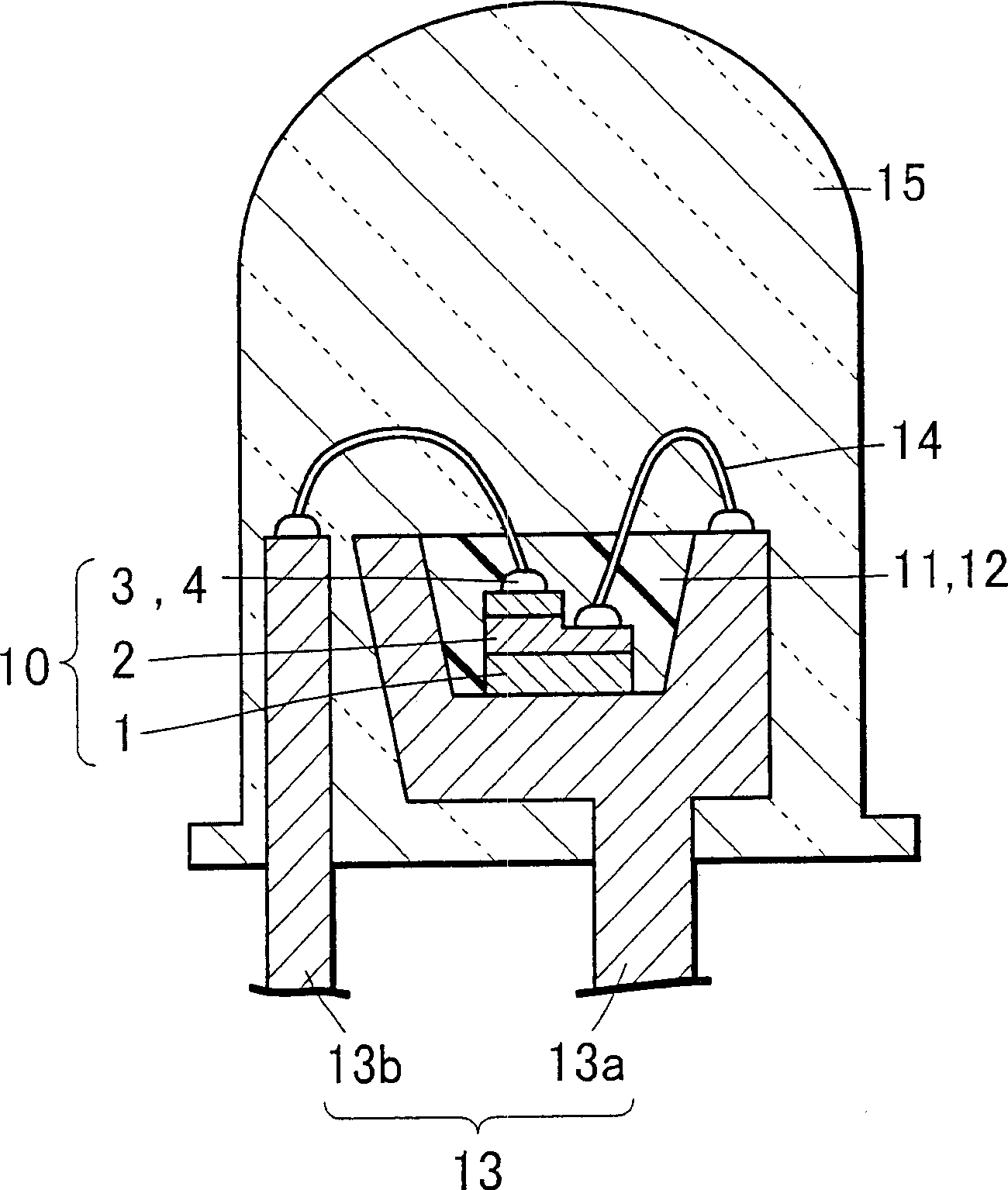

Phosphor, Method For Producing Same, And Light-Emitting Device Using Same

InactiveUS20080191607A1Short response timeReduce power consumptionDischarge tube luminescnet screensElectroluminescent light sourcesPhosphorLength wave

A Phosphor represented by the general formula Zn(1−x)AxS:E,D is characterized by having a Blue-Cu light-emitting function. In the above general formula, A represents at least one group 2A element selected from the group consisting of Be, Mg, Ca, Sr and Ba; E represents an activator containing Cu or Ag; D represents a coactivator containing at least one element selected from group 3B and group 7B elements; and x represents a mixed crystal ratio satisfying 0≦x<1. The activator is preferably contained at a molar concentration equal to or higher than that of the coactivator for obtaining emission of short wavelength. As the activator, Cu and Ag are respectively used by themselves, while Ag can be suitably used in combination with Au.

Owner:SUMITOMO ELECTRIC IND LTD

Warm-white light emtitting diode and its halide phosphor powder

InactiveUS20100044729A1Effective efficiencyEffective lightingDischarge tube luminescnet screensElectroluminescent light sourcesCeriumLight-emitting diode

The invention relates to a halide phosphor powder for warm-white light emitting diode, which is a kind of low-color-temperature phosphor powder of halide nitride based on garnet of rare earth oxides, uses cerium as activating agent and is characterized in that chloride (Cl−1) and nitrogen ion (N−3) are added to the composition of the phosphor powder and its stoichiometric relationship of the composition is (ΣLn+3)3Al2[(Al(O1-2pClpNp)4]3, wherein ΣLn is ΣLn=Y and / or Gd and / or Tb and / or Lu and / or Dy and / or Pr and / or Ce. In addition, the invention also discloses a use of a warm-white light emitting diode of the said phosphor powder with a weight ratio of 8 to 75%. The light emitting diode has a warm-red color temperature T≦3000 K when it has a power of 1 watt.

Owner:LO WEI HUNG

Discharge lamp comprising uv-phosphor

InactiveUS20090160341A1Long life-timeImprove lumen maintenanceSolid cathode detailsLuminescent compositionsPhosphorLanthanide

The invention is concerned with a discharge lamp provided with a gas discharge vessel comprising a gas filling with a discharge-maintaining composition, at least part of a wall of the discharge vessel being provided with a luminescent material comprising as a first UV-phosphor a lanthanide-activated lanthanum magnesium aluminate of formula Lai_xMgAlπOic>:Lnx, wherein the lanthanide Ln is selected from the group of Ce(III), Pr(III), Nd(III) and Gd(III), and 0.001<x<0.5, which discharge lamp is further provided with means for generating and maintaining a gas discharge. If it comprises gadolinium as an activator, such a lamp is especially useful for narrow-band UV-B phototherapy. The invention is also concerned with an UV-phosphor in the form of a lanthanide-activated lanthanum magnesium aluminate of formula Lai_xMgAlπOic>:Lnx, wherein the lanthanide Ln is selected from the group of Ce(III), Pr(III), Nd(III) and Gd(III), and 0.001<x<0.5.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

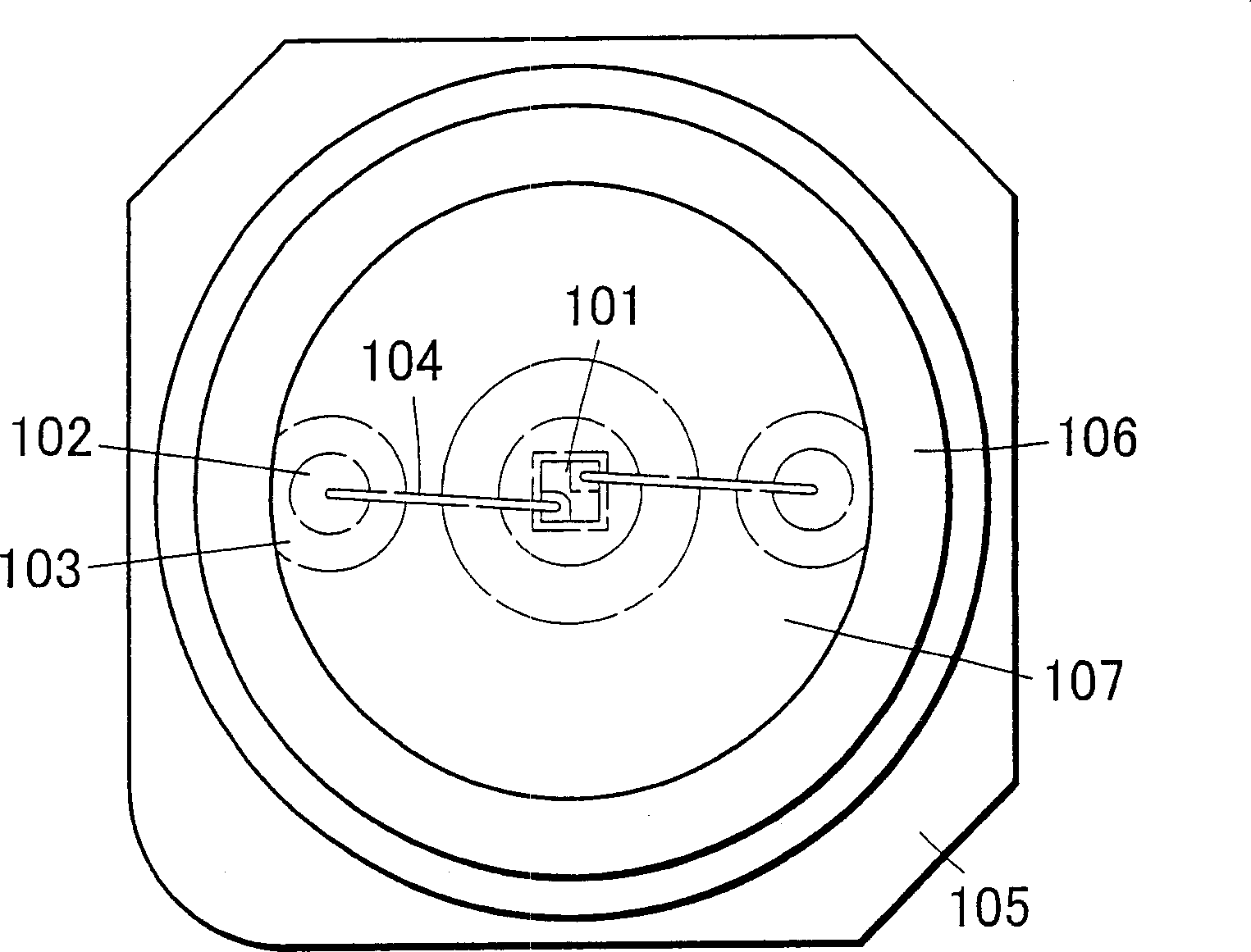

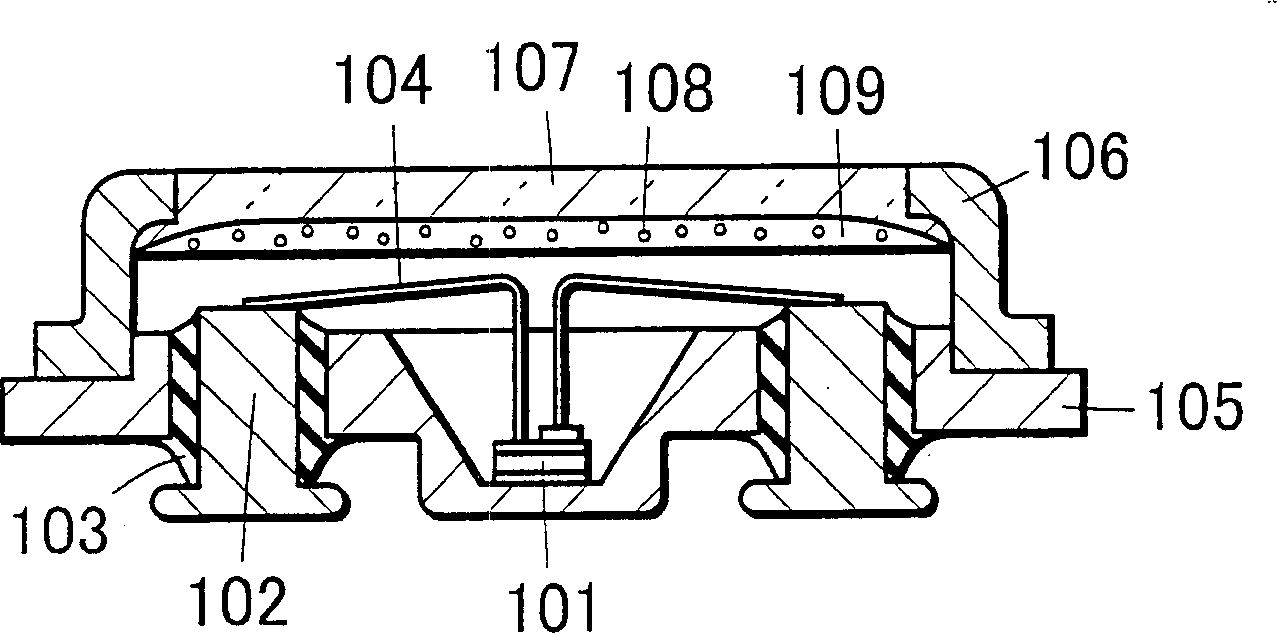

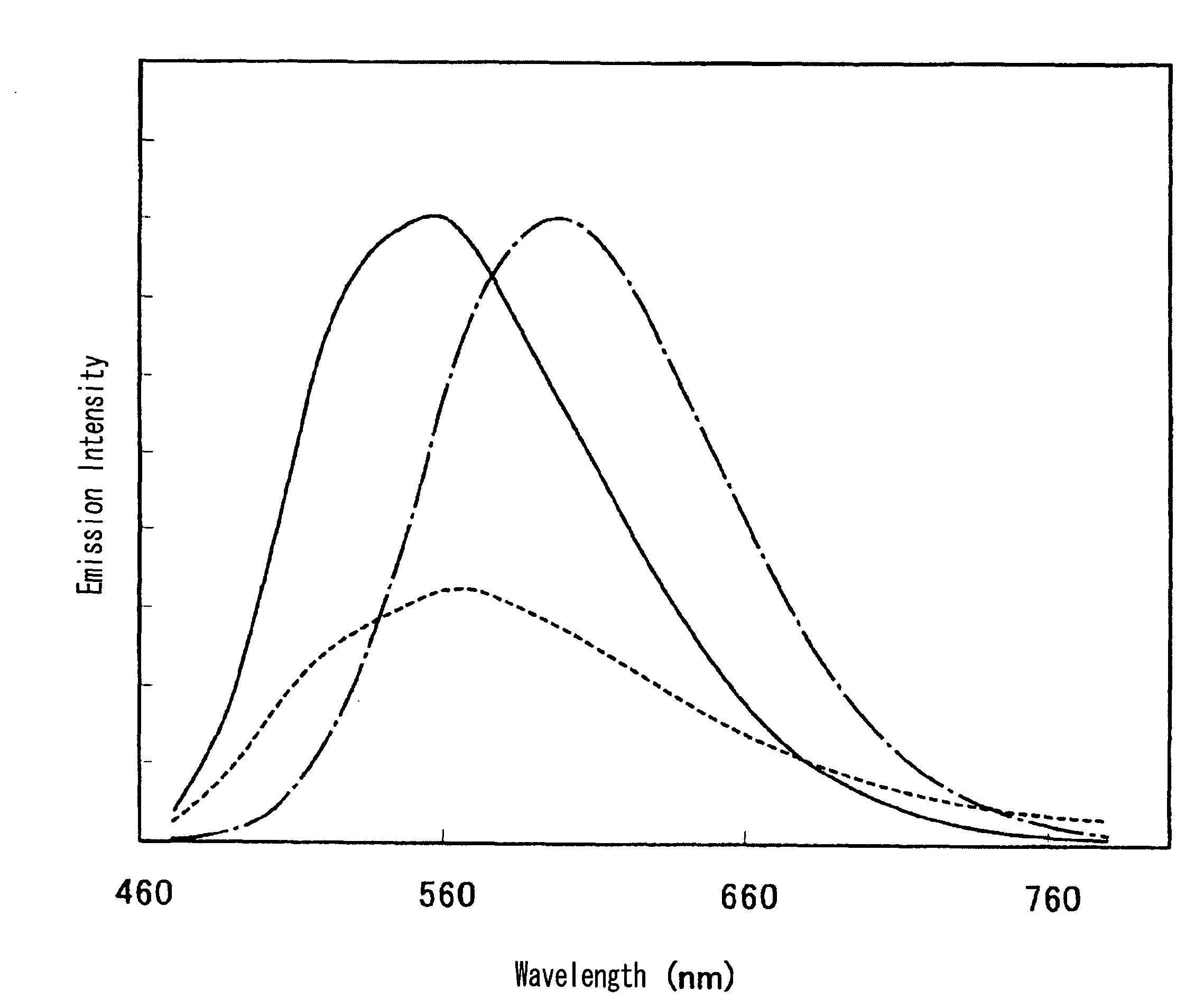

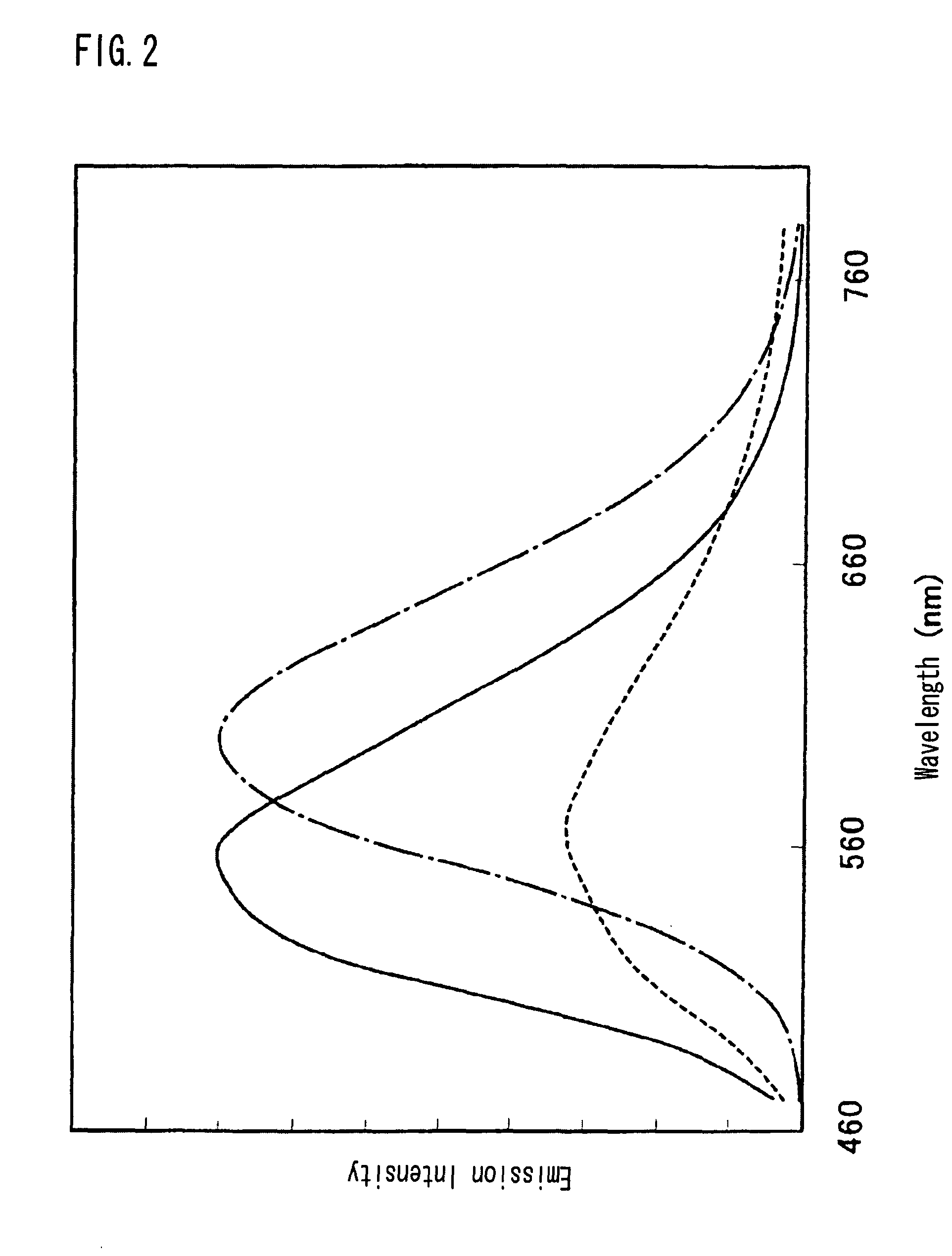

Phosphor and manufacturing method therefore, and light emission device using the phosphor

InactiveUS8062549B2Improve emission characteristicsBroad emission spectrumDischarge tube luminescnet screensElectroluminescent light sourcesFluorescenceUltraviolet

To provide a phosphor for manufacturing an one chip type LED illumination, etc, by combining a near ultraviolet / ultraviolet LED and a blue LED, and having an excellent emission efficiency including luminance. The phosphor is given as a general composition formula expressed by MmAaBbOoNn:Z, (where element M is one or more kinds of elements having bivalent valency, element A is one or more kinds of elements having tervalent valency, element B is one or more kinds of elements having tetravalent valency, O is oxygen, N is nitrogen, and element Z is one or more kinds of elements acting as an activator.), satisfying a=(1+x)×m, b=(4−x)×m, o=x×m, n=(7−x)×m, 0≦x≦1, wherein when excited by light in a wavelength range from 300 nm to 500 nm, the phosphor has an emission spectrum with a peak wavelength in a range from 500 nm to 620 nm.

Owner:MITSUBISHI CHEM CORP

Light emitting device having thio-selenide fluorescent phosphor

InactiveUS7109648B2Discharge tube luminescnet screensElectroluminescent light sourcesPhotophoreThio-

Provided herein are novel phosphors useful in the manufacture of white light emitting diodes. The phosphors provided by the invention are described by the formulae:MA2(SxSey)4:Band / orM2A4(SxSey)7:Bin which x, and y are each independently any value between 0 and 1, including 0 and 1 subject to the proviso that the sum of x and y is equal to any number in the range of between about 0.75 and about 1.25; M is at least one of Be, Mg, Ca, Sr, Ba, Zn; A is at least one of Al, Ga, In, Y, La, and Gd; and wherein the activator(s), B, comprises one or more element selected from the group consisting of: Eu, Ce, Cu, Ag, Al, Tb, Cl, Br, F, I, Mg, Pr, K, Na, and Mn, including mixtures comprising any two, any three, any four, any five, any six, any seven, or more of these elements in any proportion, and wherein the elements in these mixtures may each independently be present in any amount between 0.0001% and about 10% in mole percent based on the total molar weight of said composition.Standard techniques used in phosphor deposition for the manufacture of light emitting diodes which comprise phosphors may be employed to produce LED's having a white light output when the phosphors of the invention are utilized.

Owner:PHOSPHORTECH

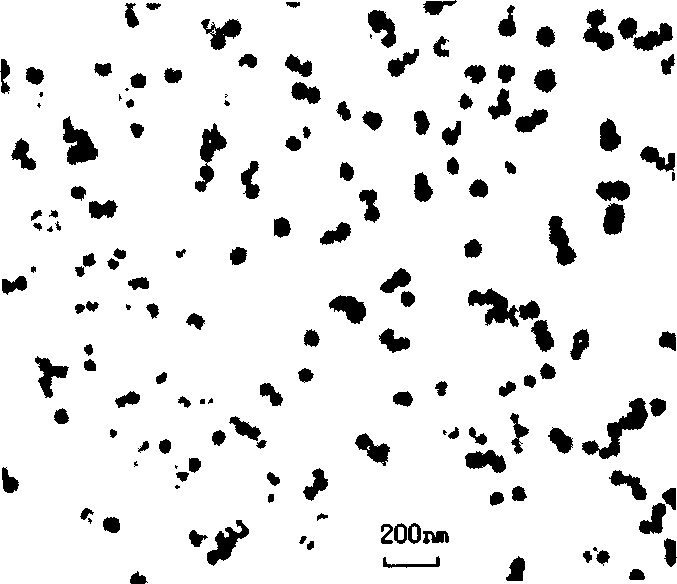

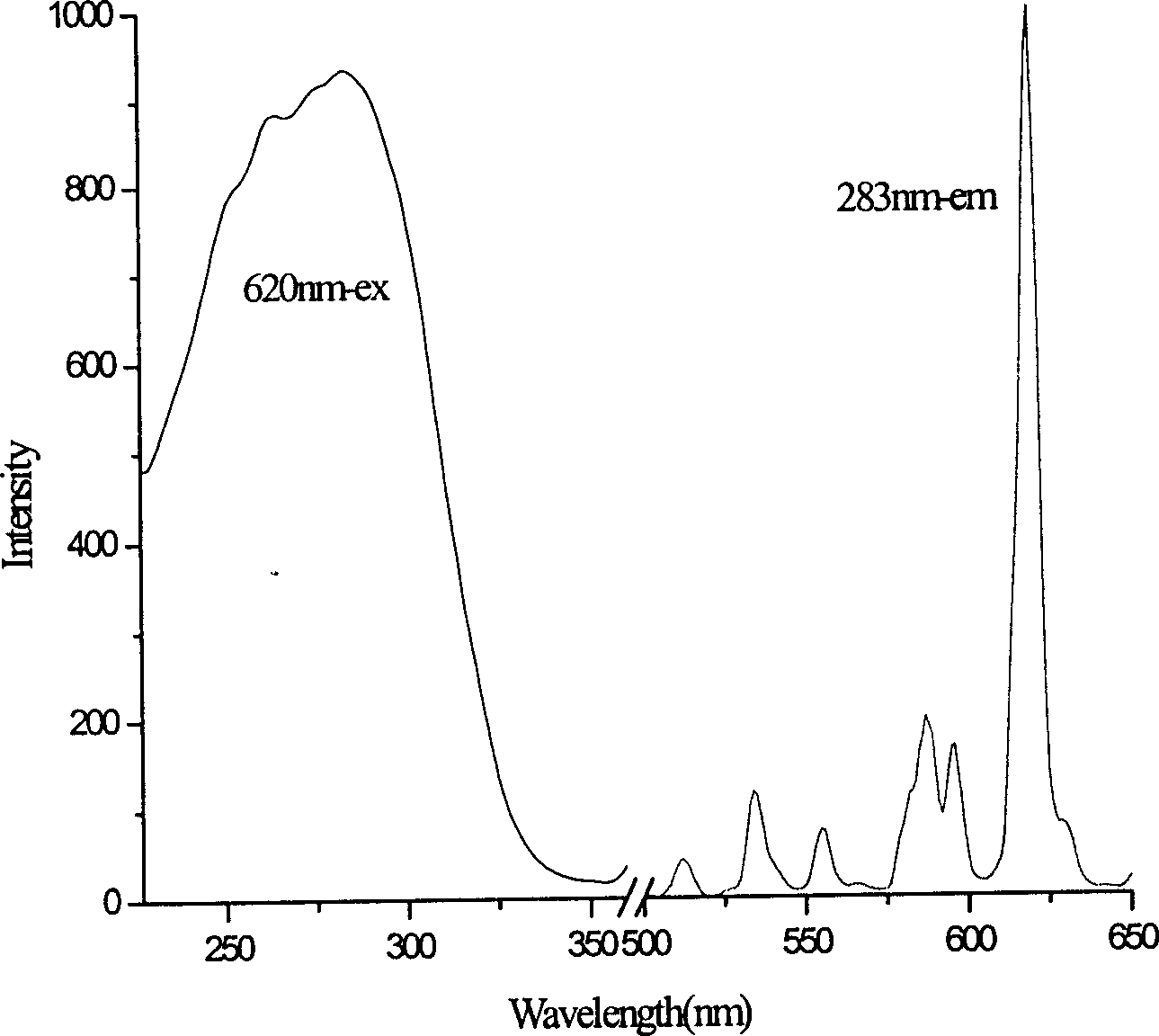

Rare earth nano silicate red phosphor and its preparation method

InactiveCN1702145AImprove light color purityFine particle sizeLuminescent compositionsLuminous intensityEngineering

The invention discloses a rare-earth nanometer metasilicate red fluorophor and the method for preparation. It contains the following setups: dissolving sensitizer activator substrate yttrium oxide in norbiline (or azotic acid), pressure-reduced distilling to eliminate water and excess acid, adding alcohol to prepare clear and transparent solution, and adding substrate silicon material to prepare transparent sol, pressure-reduced distilling to eliminate alcohol and acquiring powder solid, and adglutinating in 550-750 Deg. C by 2-4 hours to prepare the product. It prepares rare-earth nanometer red fluorescent powder in a low temperature (600 Deg. C) and a short time (3 hours), the average grain diameter being about 60-80 nm, the luminous intensity strong, chemical and optical property stable, the material easily obtained and cheap. Chemical expression formula of the rare-earth nanometer red fluorescent powder is as following: (YxSiy0z: Euj, Mn.

Owner:SHANGHAI NORMAL UNIVERSITY

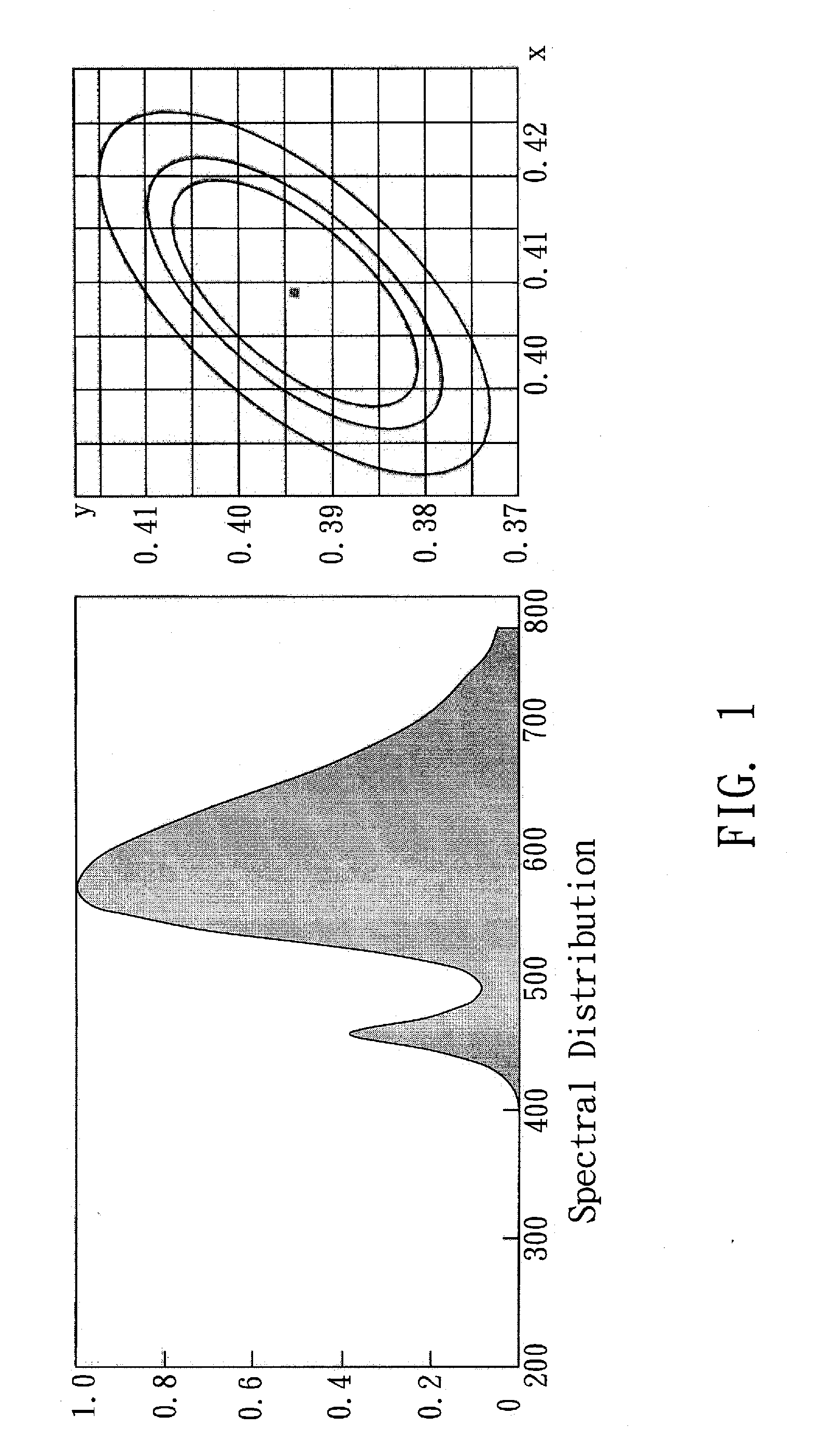

Phosphor and optical device using same

A phosphor for converting ultraviolet light or blue light emitted from a light emitting element into a visible white radiation having a high level of color rendering properties, containing a light emitting component prepared from a solid system of an alkaline earth metal antimonate and a system derived from the solid system and exhibiting intrinsic photoemission, such as a fluoroantimonate, a light emitting component prepared from a manganese(IV)-activated antimonate, a titanate, silicate-germanate, and an aluminate, a light emitting component prepared from a europium-activated silicate-germanate or from a system containing a sensitizer selected from a group consisting of europium (II) and manganese (II) as a secondary activator and having an orange color or a dark red color in the spectrum range over 600 nm, or a light emitting component composed of a mixture of eight or less light emitting components having different emission bands and brought to a state of continuous emission of about 380 to 780 nm exhibiting a color temperature of about 10,000 to 6,500 K and a color temperature of about 3,000 to 2,000 K by virtue of the superposition of the light emitting bands.

Owner:TOYODA GOSEI CO LTD +2

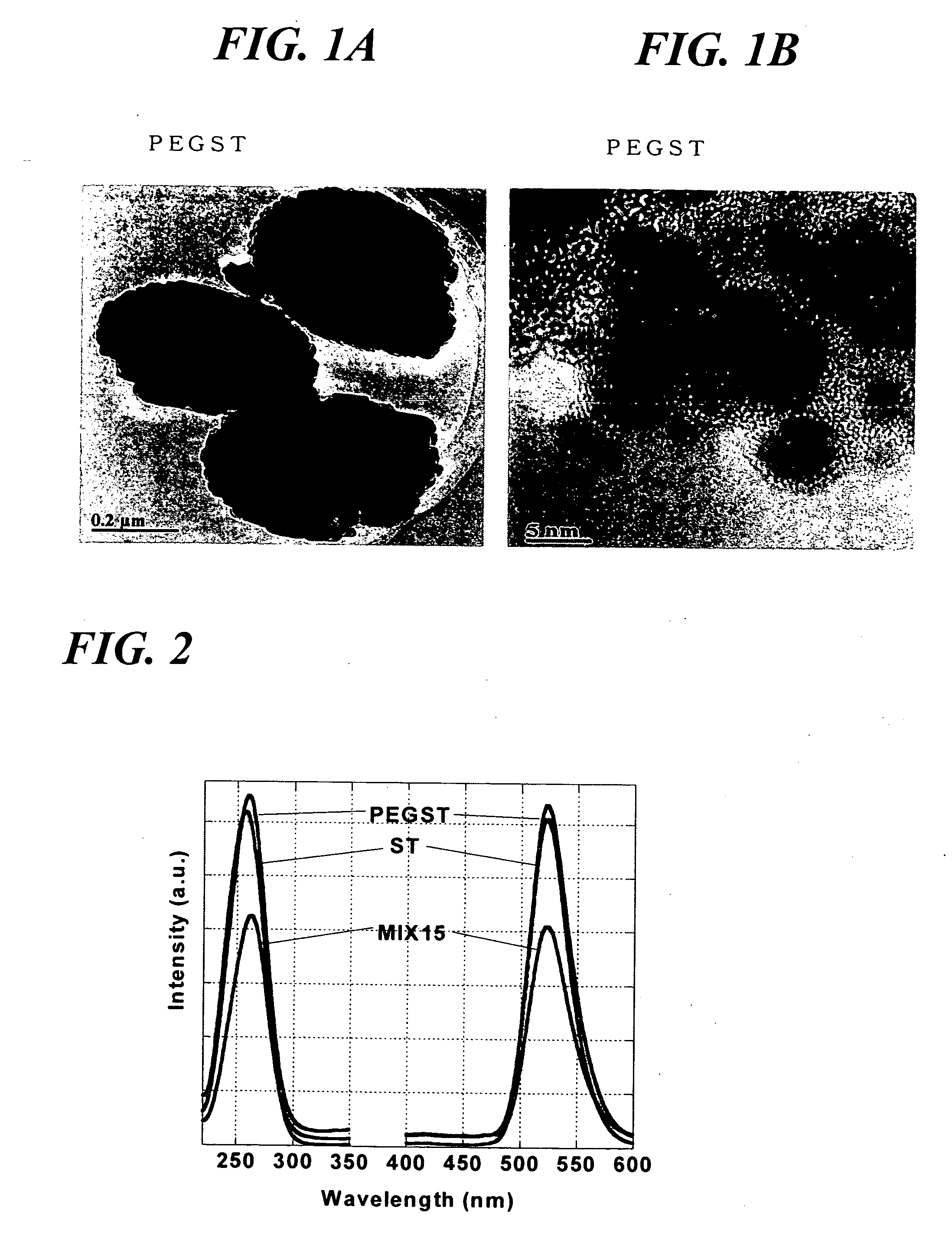

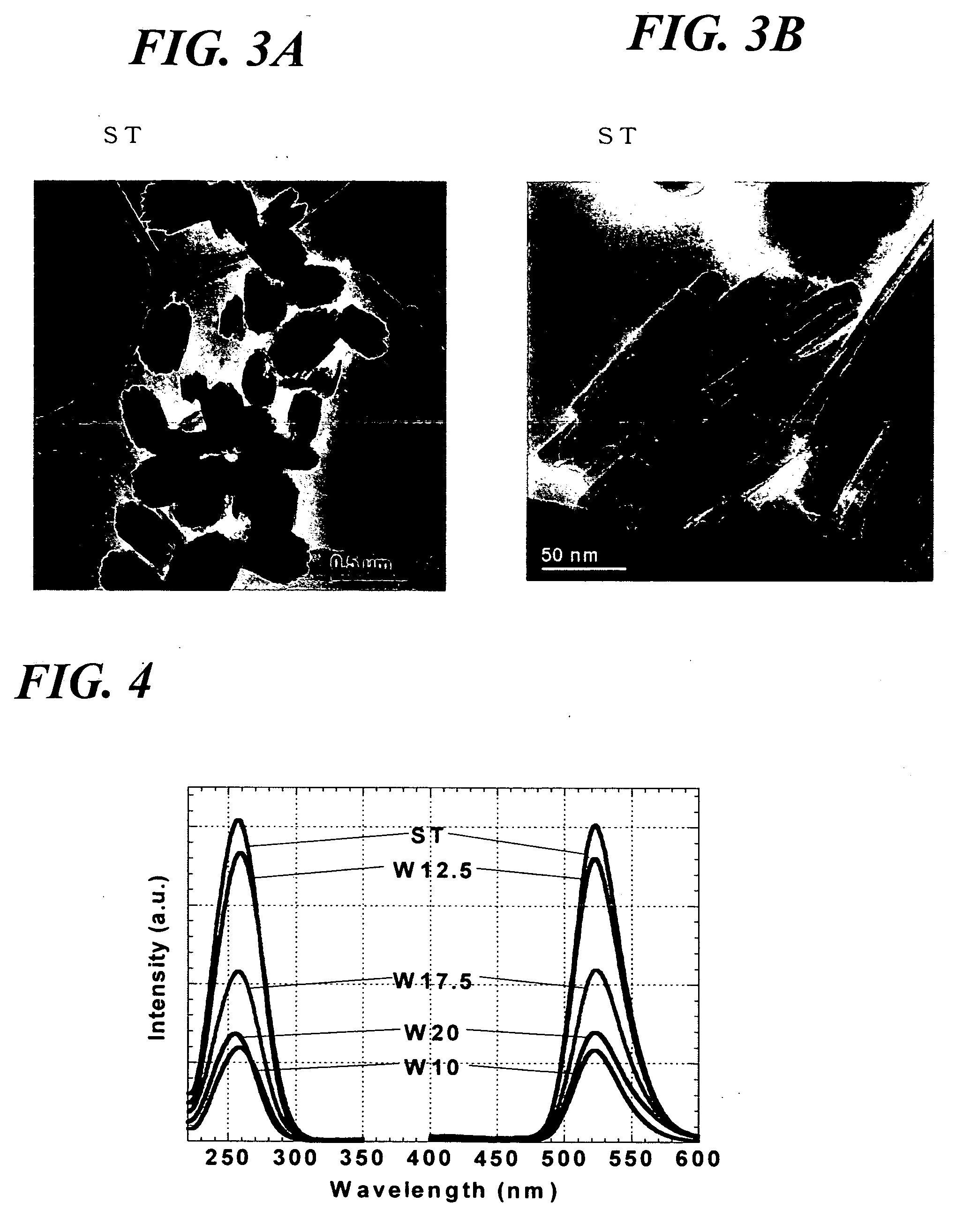

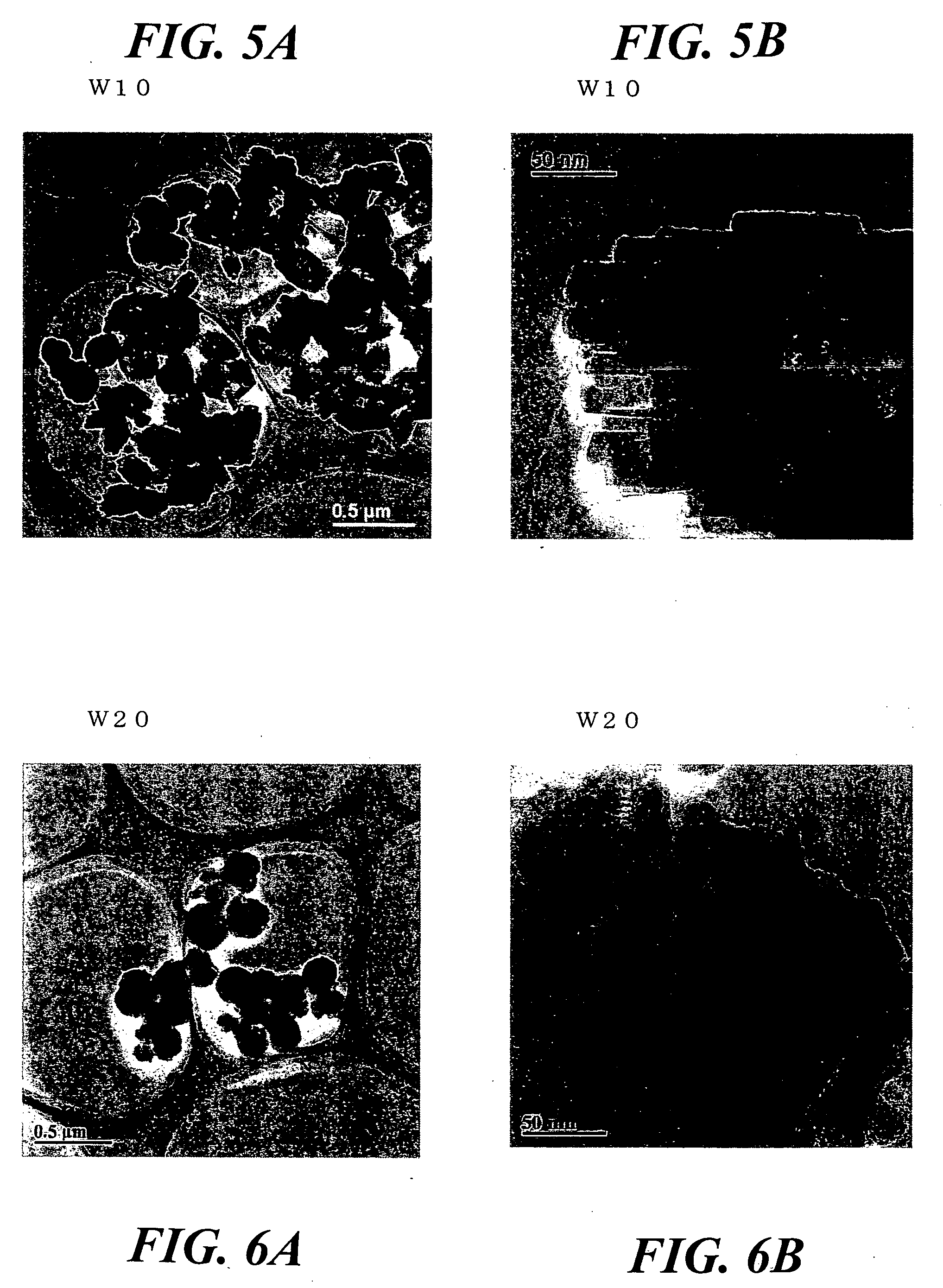

Phosphor and production process for the same

InactiveUS20060011890A1Suppressing anisotropic growth of crystalReduced luminous efficiencyNanotechSynthetic resin layered productsSimple Organic CompoundsPhosphor

The object of the present invention is to provide a phosphor which is excellent in transparency, light transmittance, luminescence efficiency and luminescent intensity and at the same time, processes for producing the phosphor. Preferred embodiments of the invention include a phosphor characterized in that phosphor particles represented by the general formula [(L)a(M)b(N)cOd:Y] are covered with an organic compound bearing at least one functional group at a terminal or side chain, wherein L is a metallic element such as Zn; M is a metallic element such as Al; N is Si or Ge; O is oxygen; Y is at least one activating agent such as Mn2+, Eu2+, Cu2+ or Yb2+; and a, b, c and d are each a value satisfying the relationships 0<a≦2, 0≦b≦2, 0≦c≦2 and 2a+3b+4c=2d.

Owner:KEIO UNIV

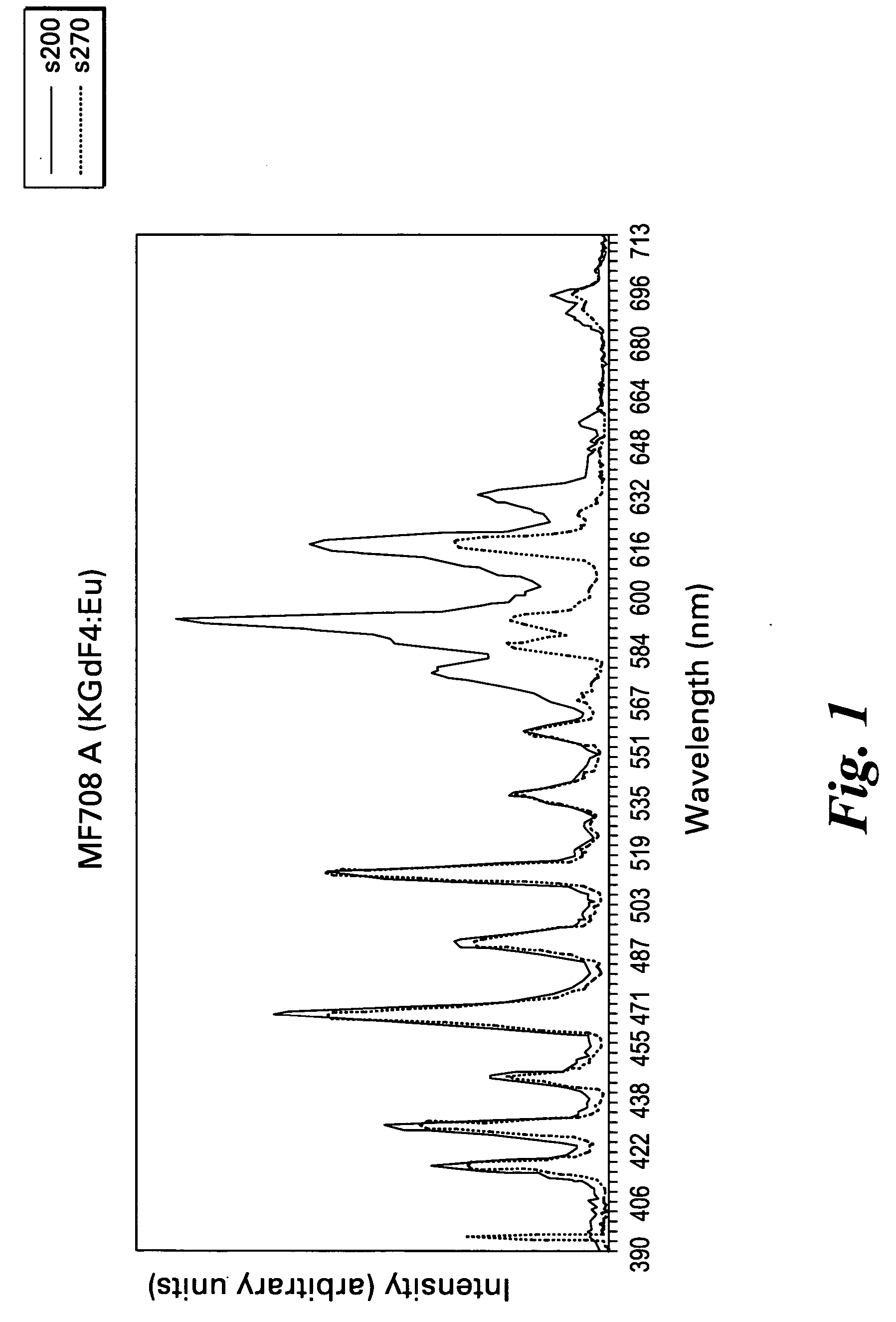

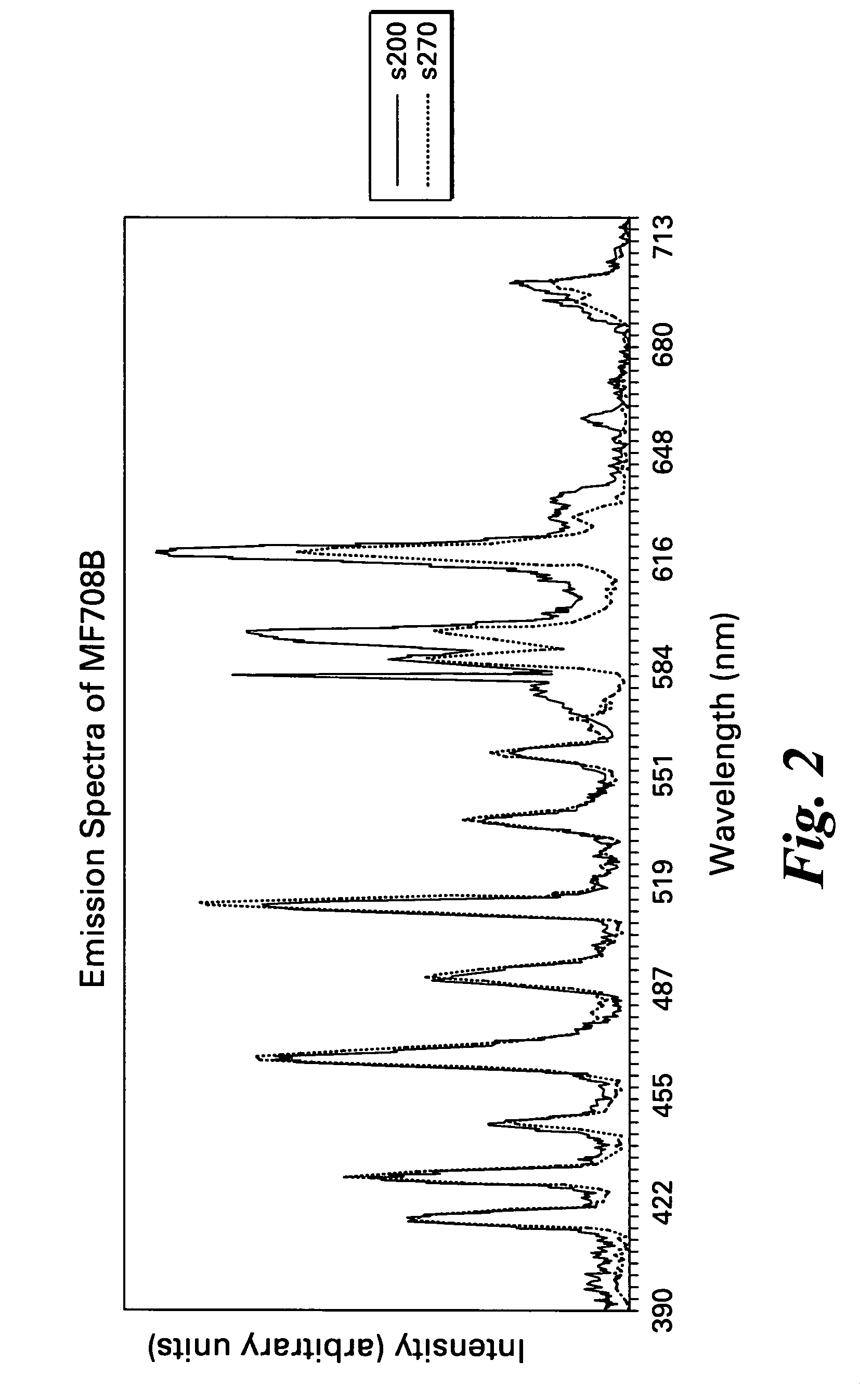

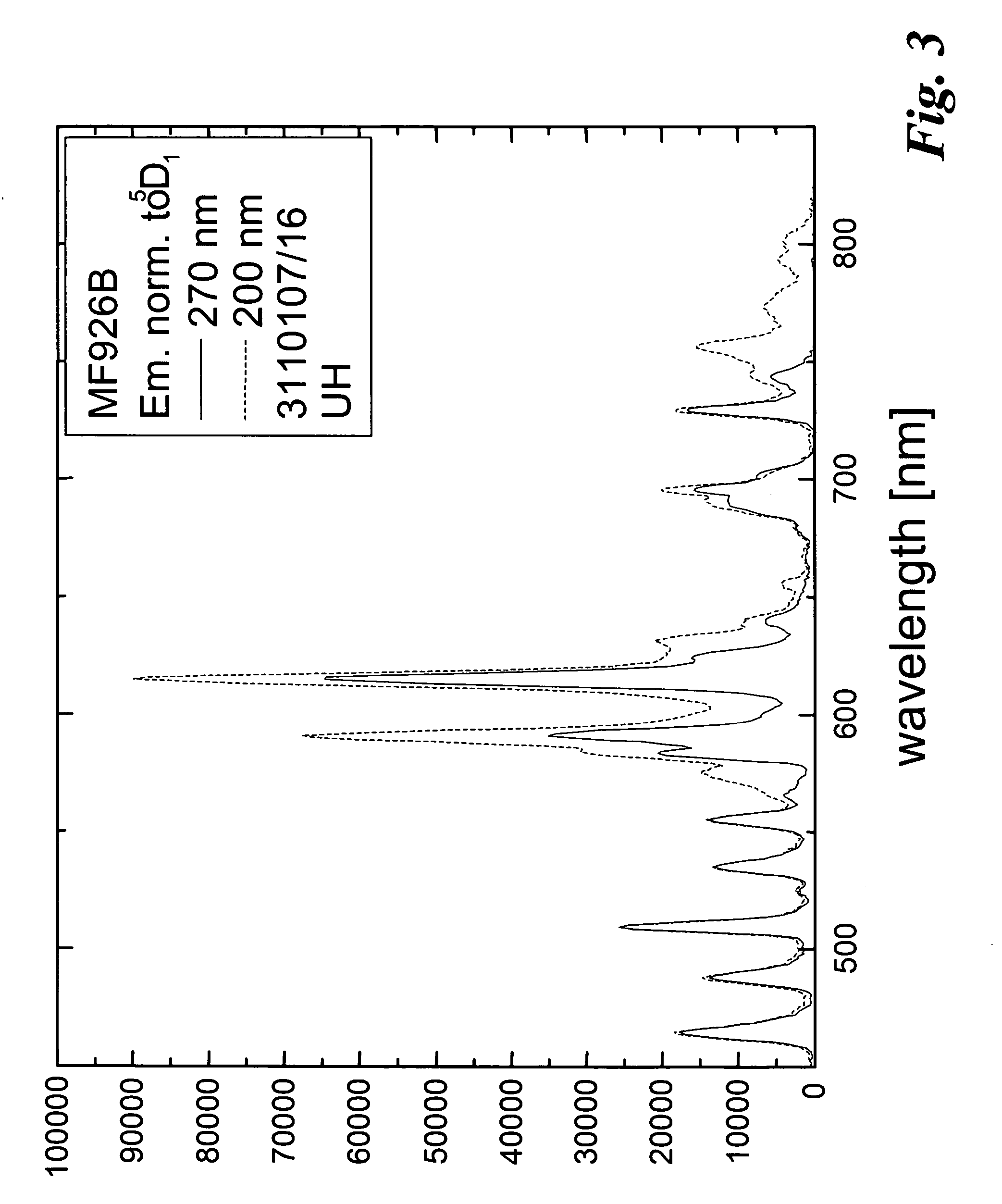

Quantum-splitting fluoride-based phosphors, method of producing, and radiation sources incorporating same

InactiveUS20060151747A1Easy to optimizeSufficient quantityDischarge tube luminescnet screensCathode ray tubes/electron beam tubesPhosphorRare earth

A quantum-splitting fluoride-based phosphor comprises gadolinium, at least a first alkali metal, and a rare-earth metal activator. The phosphor is made in a solid-state method without using HF gas. The phosphor can be used alone or in conjunction with other phosphors in light sources and displays wherein it can be excited by VUV radiation, and increases the efficiency of these devices

Owner:GENERAL ELECTRIC CO

Long persistence phosphorescence material in yellow light containing no rare earth activator, and preparation method

A yellow long persistence phosphorescent material not containing rare-earth activator is composed of y2-x-y TixMyO2S (0<x<0.15, 0 is less than or equal to y<0.15, M=Li, K, Ag, Au, Cd, Zn, Co, Ni, Cu, Mg, Ca, Sr and Ba) and it is especially for yellow long persistence phosphorescent material of Y2-xTiO2S (0<x<0.15). The preparing method includes applying solid phase reaction or wet chemical process to synthetize yellow long persistence phosphorescent meterial of T2-xTiO2S and Y2-x-yTixMyO2S by single-doping titanium or its coactivator in substrate lattice of Y2O2S.

Owner:ZHEJIANG UNIV

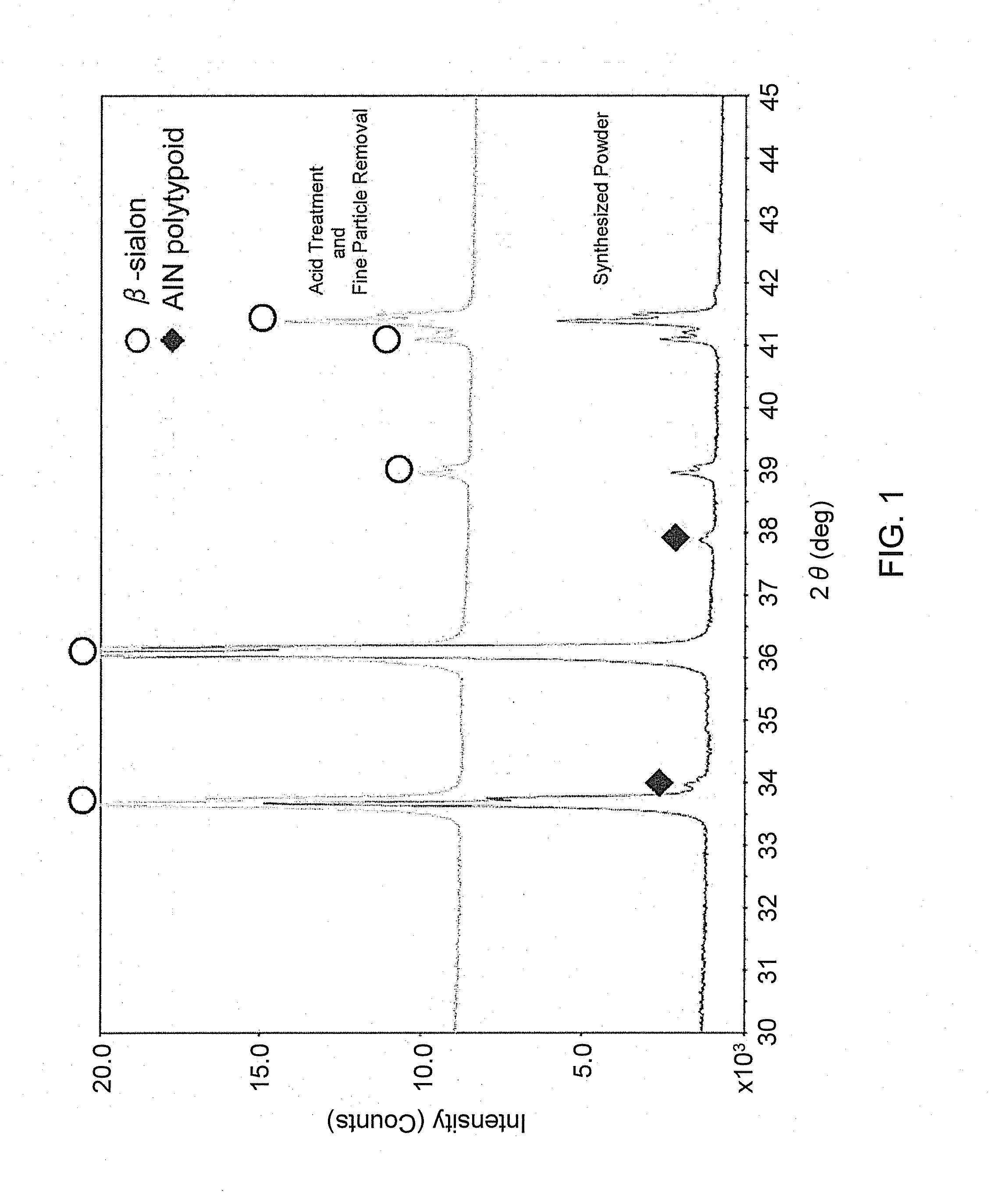

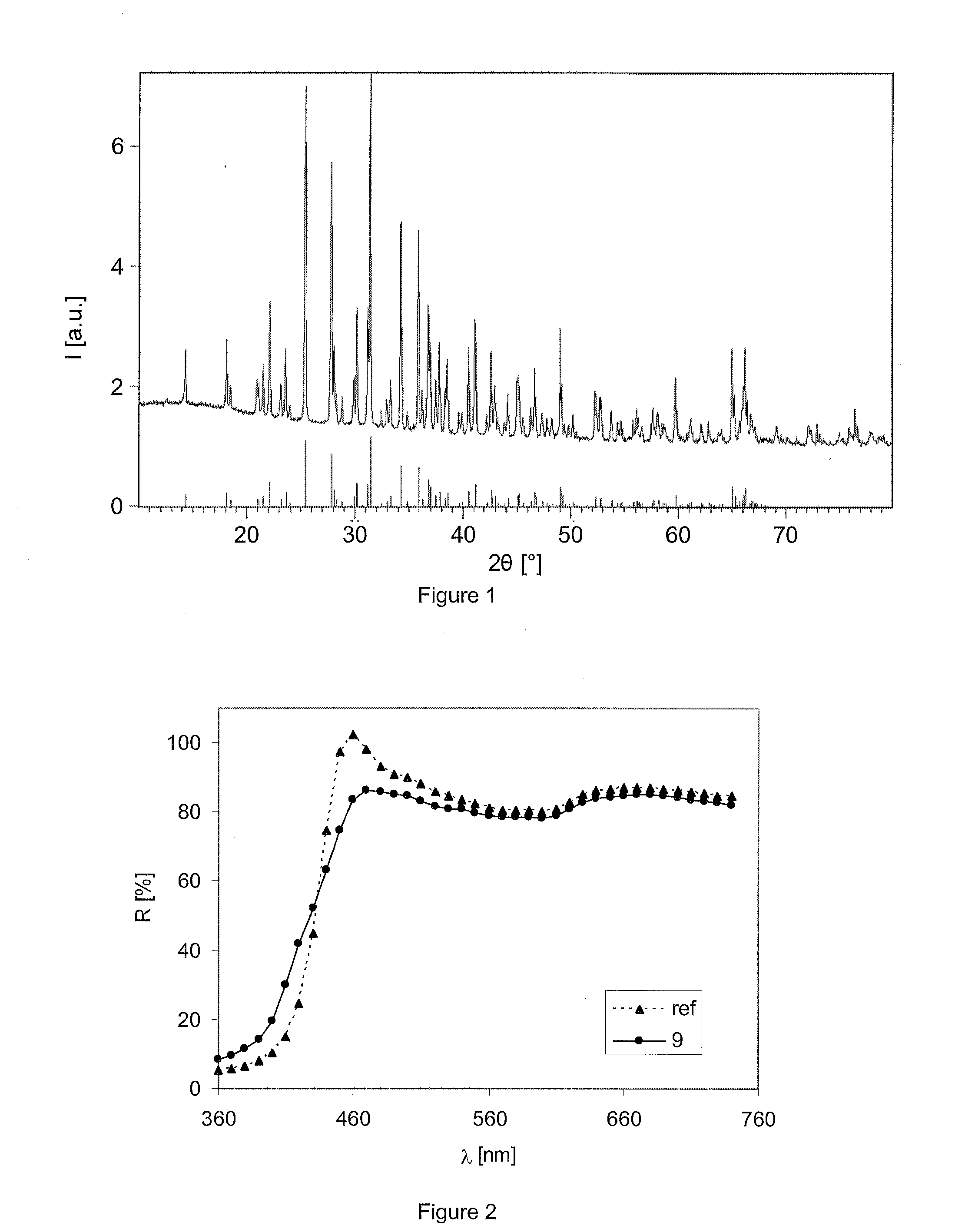

B-sialon phosphor, use thereof and method for producing same

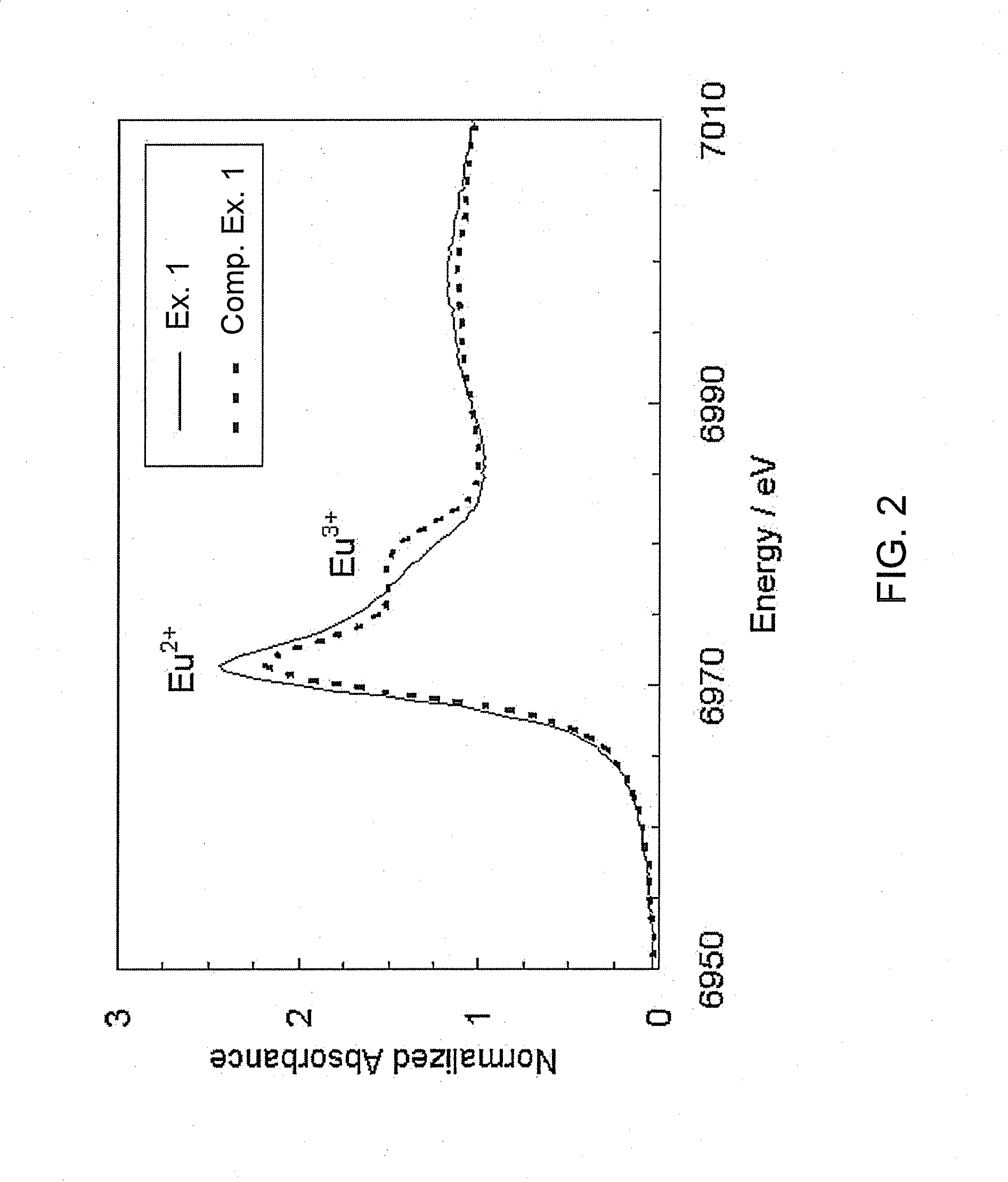

ActiveUS20110198656A1Emission efficiency be highSmall luminance changeLuminescent compositionsSemiconductor devicesChemistryCrystal

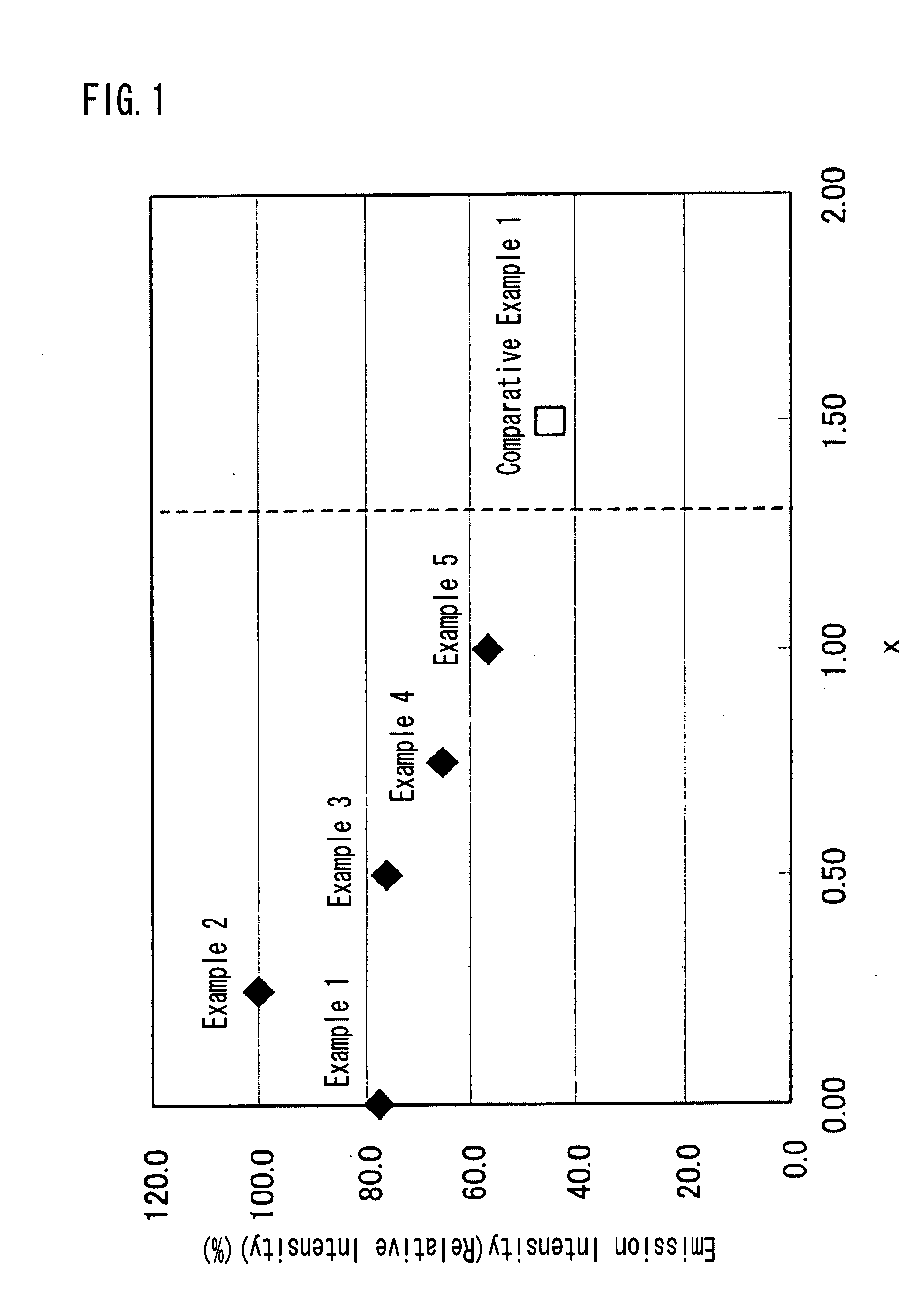

An Eu-activated β-sialon phosphor showing a high luminance, the use thereof and the method of producing the same. The β-sialon phosphor includes, as a matrix, a β-sialon crystal represented by a general formula: Si6-zAlzOzN8-z (0<z<4.2), wherein Eu, which serves as an activator, is solid-soluted in the β-sialon crystal, and the ratio of Eu2+ / (Eu2++Eu3+) is 0.8 or more. It is preferred that the amount of Eu in the solid solution is 0.1 to 1 mass % with respect to the mass of the β-sialon crystal.

Owner:DENKA CO LTD

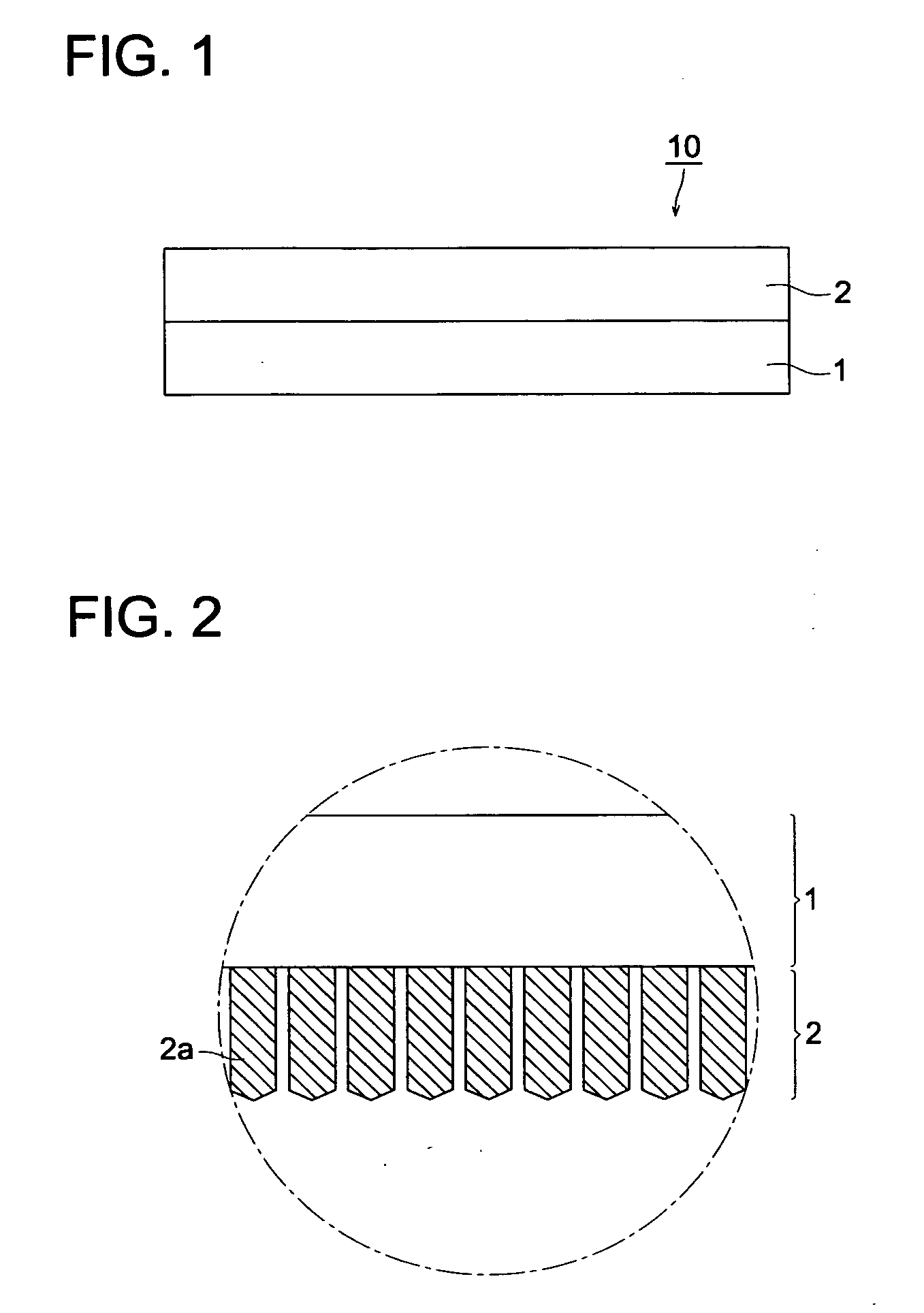

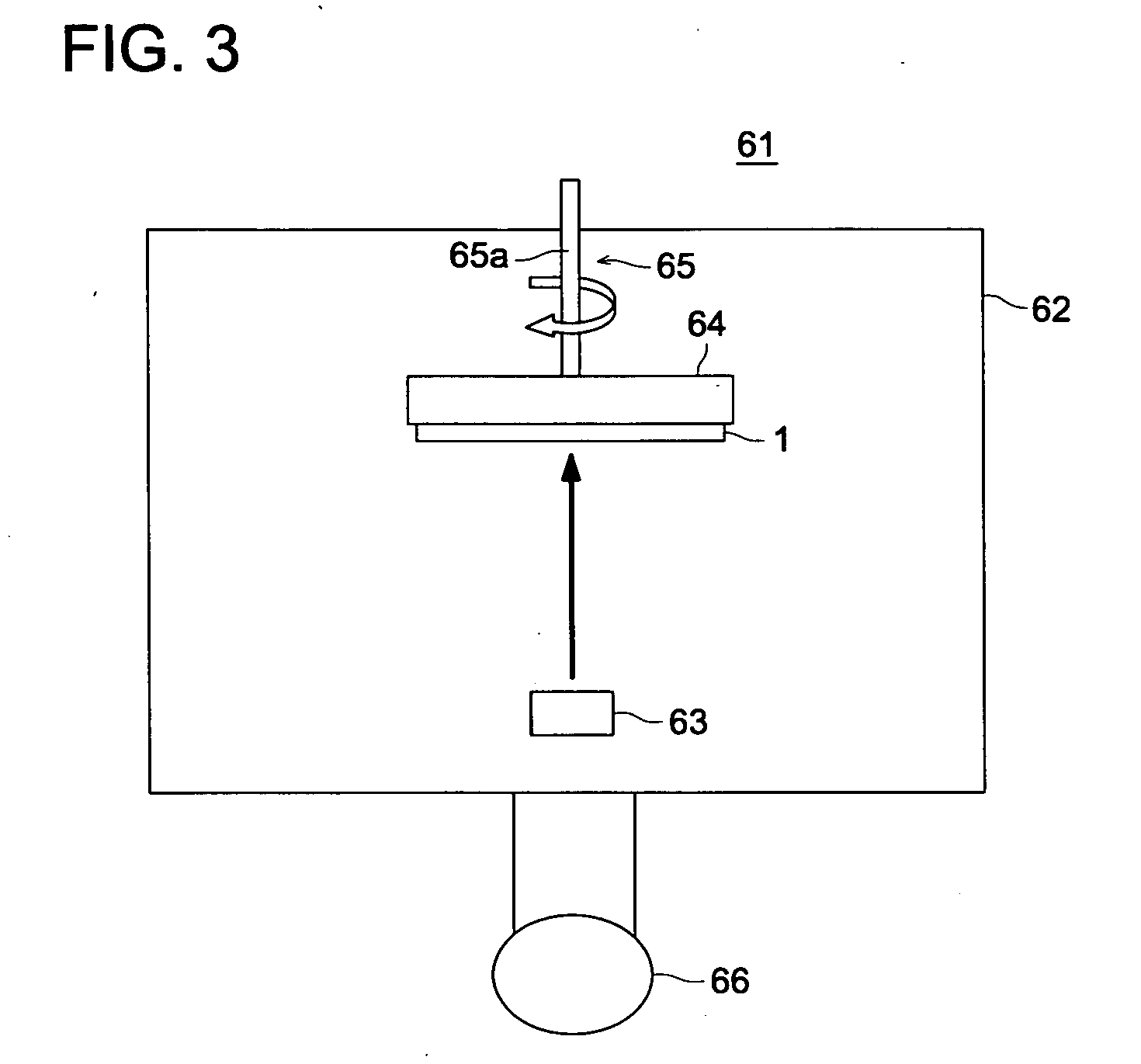

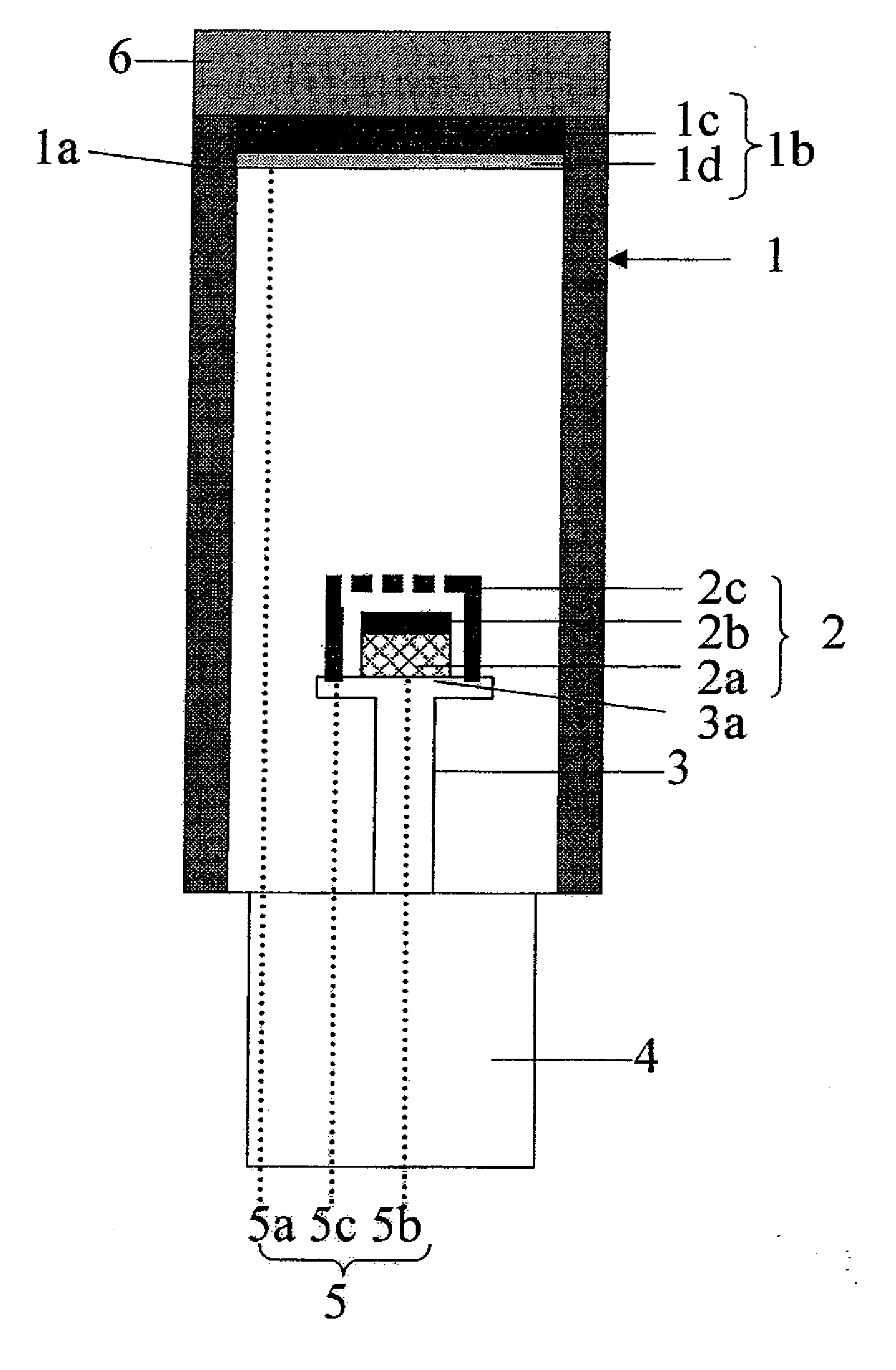

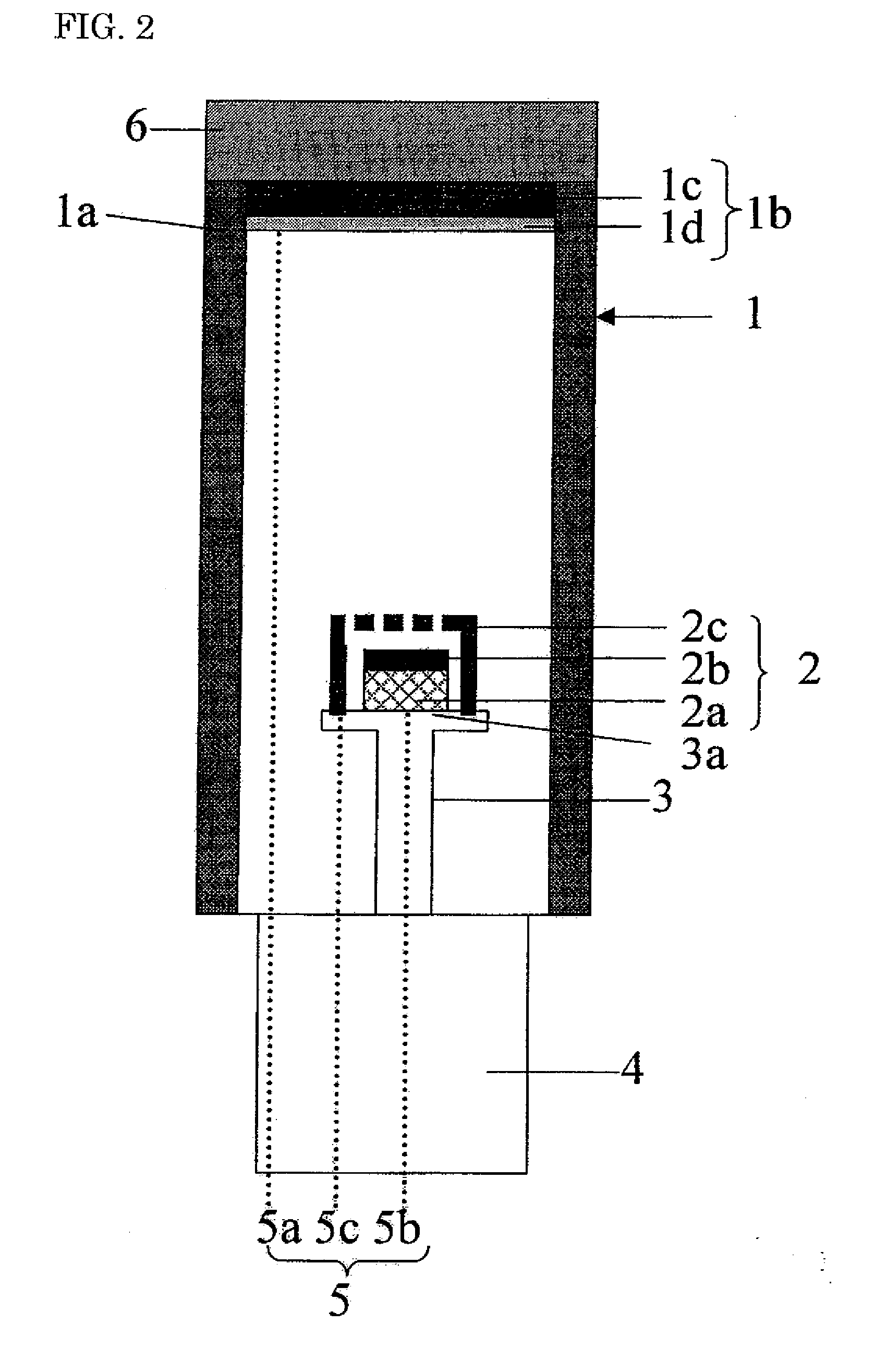

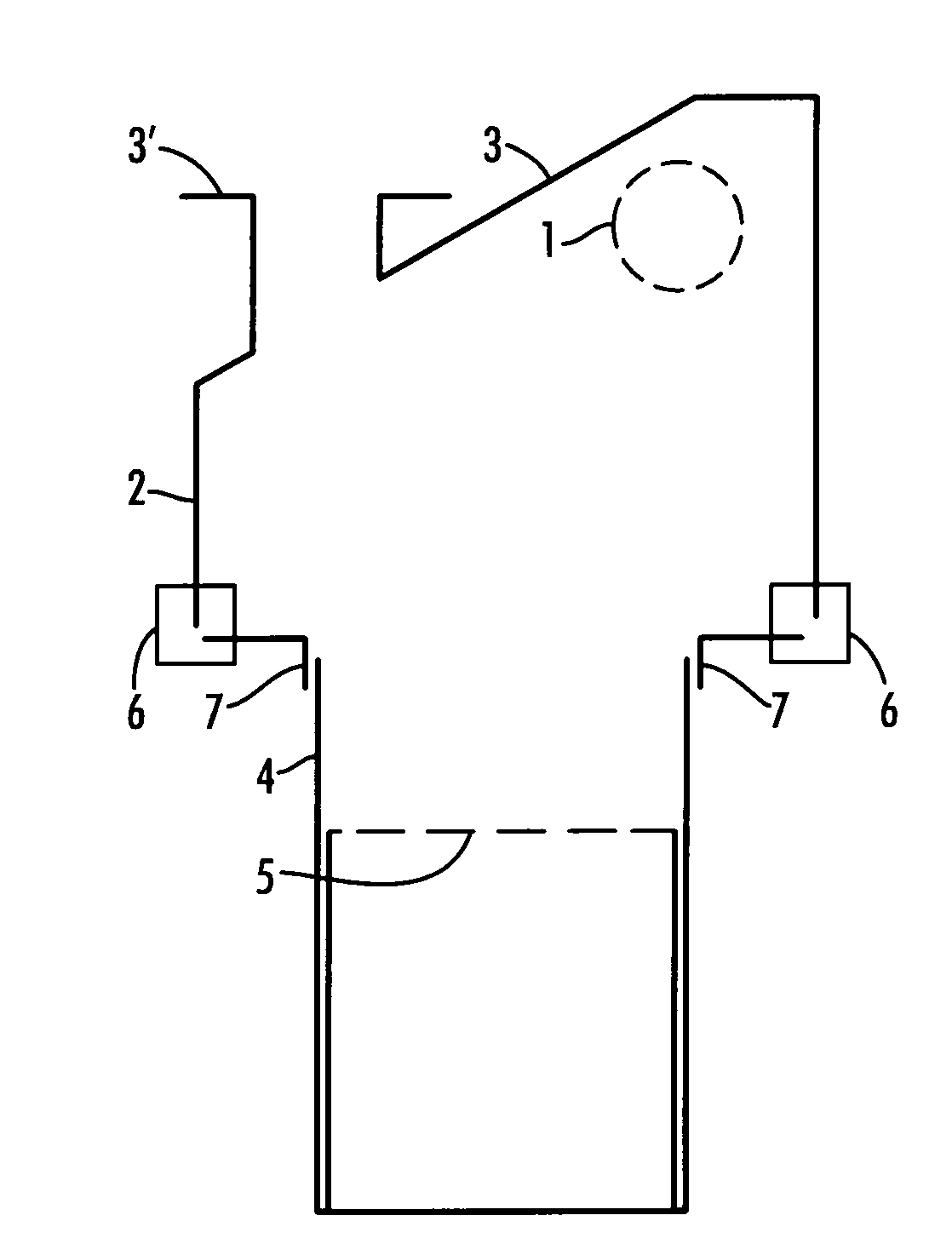

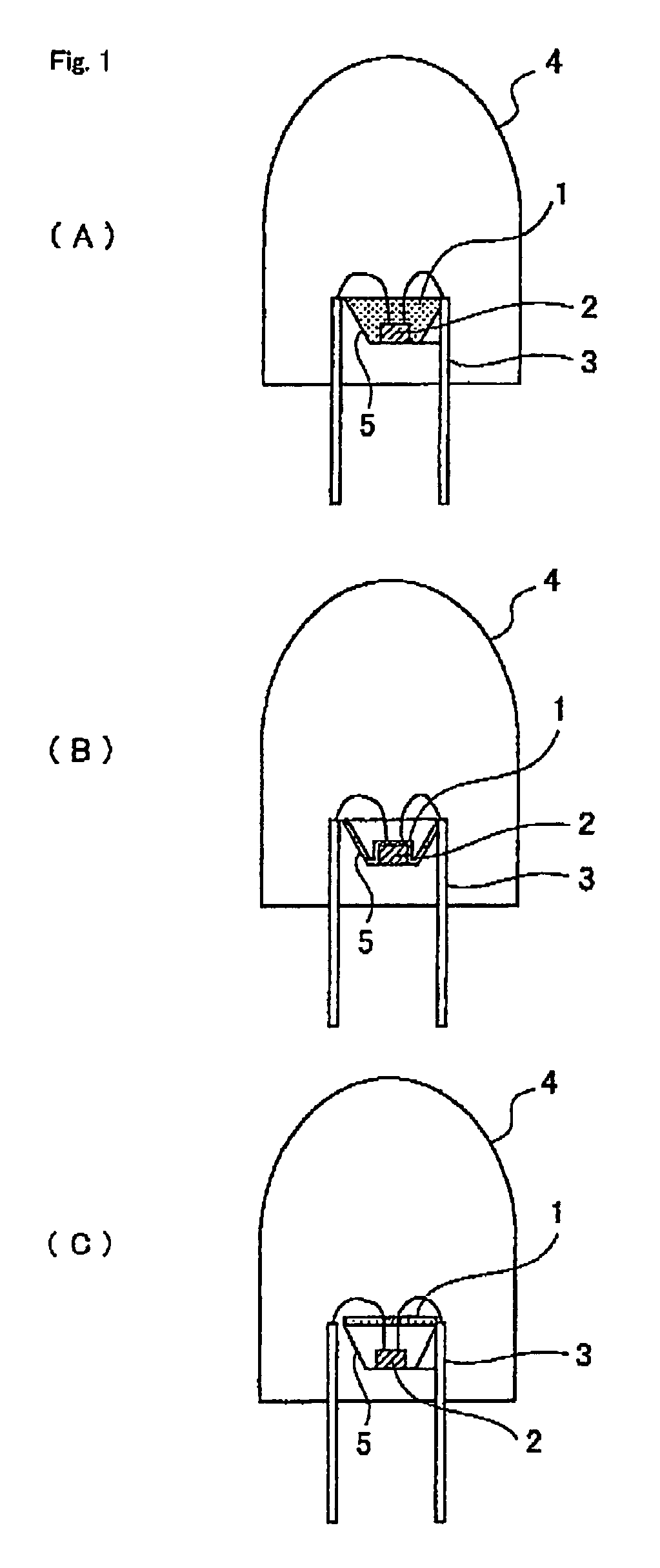

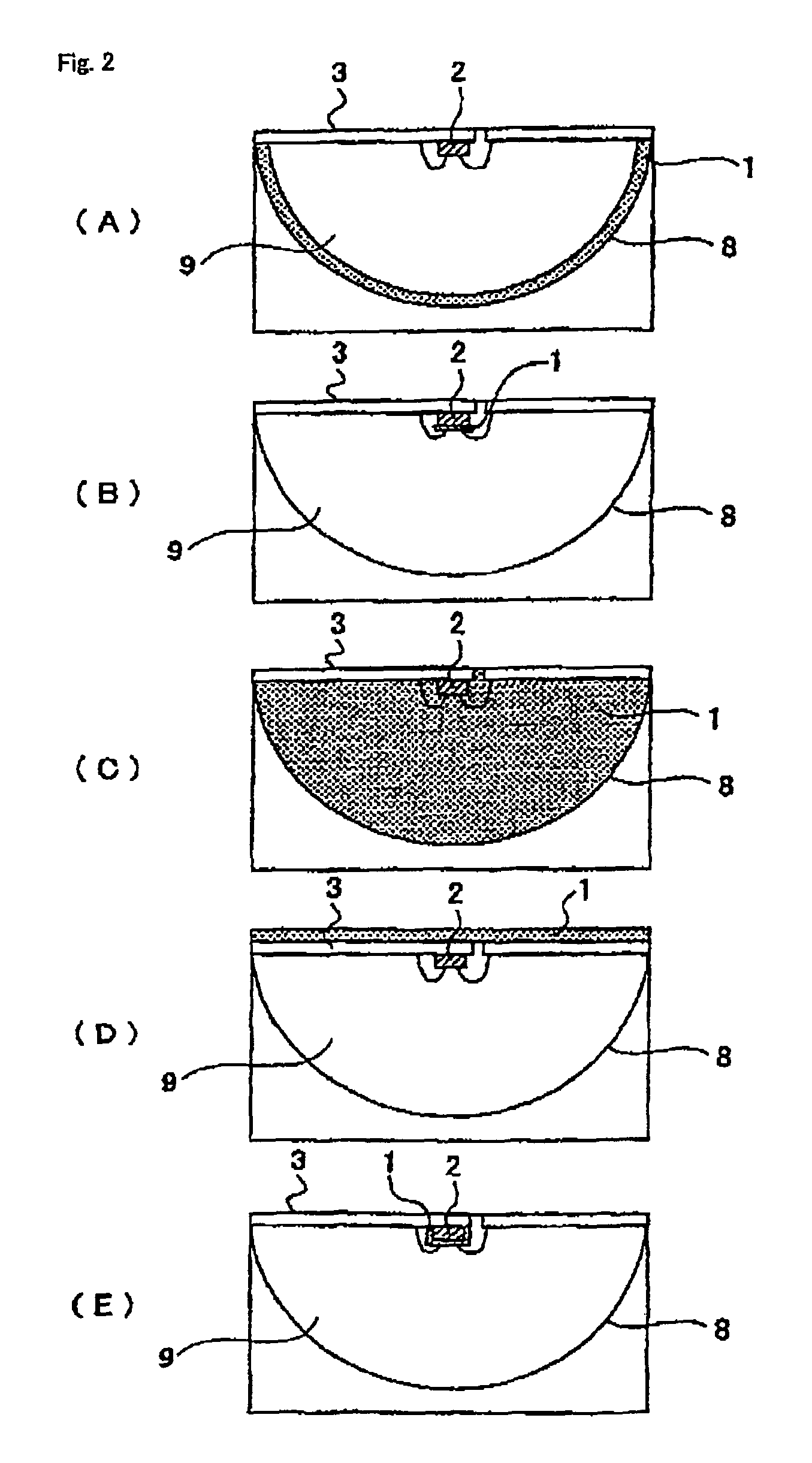

Method of forming a phosphor or scintillator material and vapor deposition apparatus used therefor

InactiveUS20090162535A1Apparent advantageVacuum evaporation coatingSputtering coatingGas phaseVapor cloud

In a method of preparing a storage phosphor or a scintillator layer on a support by vapor depositing from a crucible unit in a vapor deposition apparatus, while heating as phosphor or scintillator precursor raw materials a matrix component and an activator component or a precursor component thereof, said crucible unit comprises a bottom and surrounding side walls as a container for the said phosphor or scintillator precursor raw materials present in said crucible, said crucible is provided with an internal lid with perforations (5) and said crucible unit further comprises a chimney as part of the said crucible unit and a slit allowing molten, liquefied phosphor or scintillator precursor raw materials to escape in vaporized form under reduced pressure from said crucible unit in order to become deposited as a phosphor or scintillator layer onto said support; and at least one heating means (1) in the chimney (2) is positioned under a heat shield with a slit (3) and a slot outlet (3′), covering thereby said crucible unit and making part of said chimney (2), so that said heating means (1) cannot be observed when looking into the vaporization unit through said slot outlet (3′) from any point in the plane of the said support present as a vapor deposition target in the said vapor deposition apparatus and, while vaporizing said phosphor or scintillator precursor raw materials, a vapor cloud escapes from said slot outlet (3′) in the direction of the said support so that the ratio of the longest radius of the said vapor cloud versus the radius perpendicular thereto, when projected onto the phosphor or scintillator plate or panel from whatever an intersection through the said vapor cloud between slot outlet (3′) and support is at least 1.3, said intersection being taken parallel with the said support.

Owner:T2PHARMA GMBH

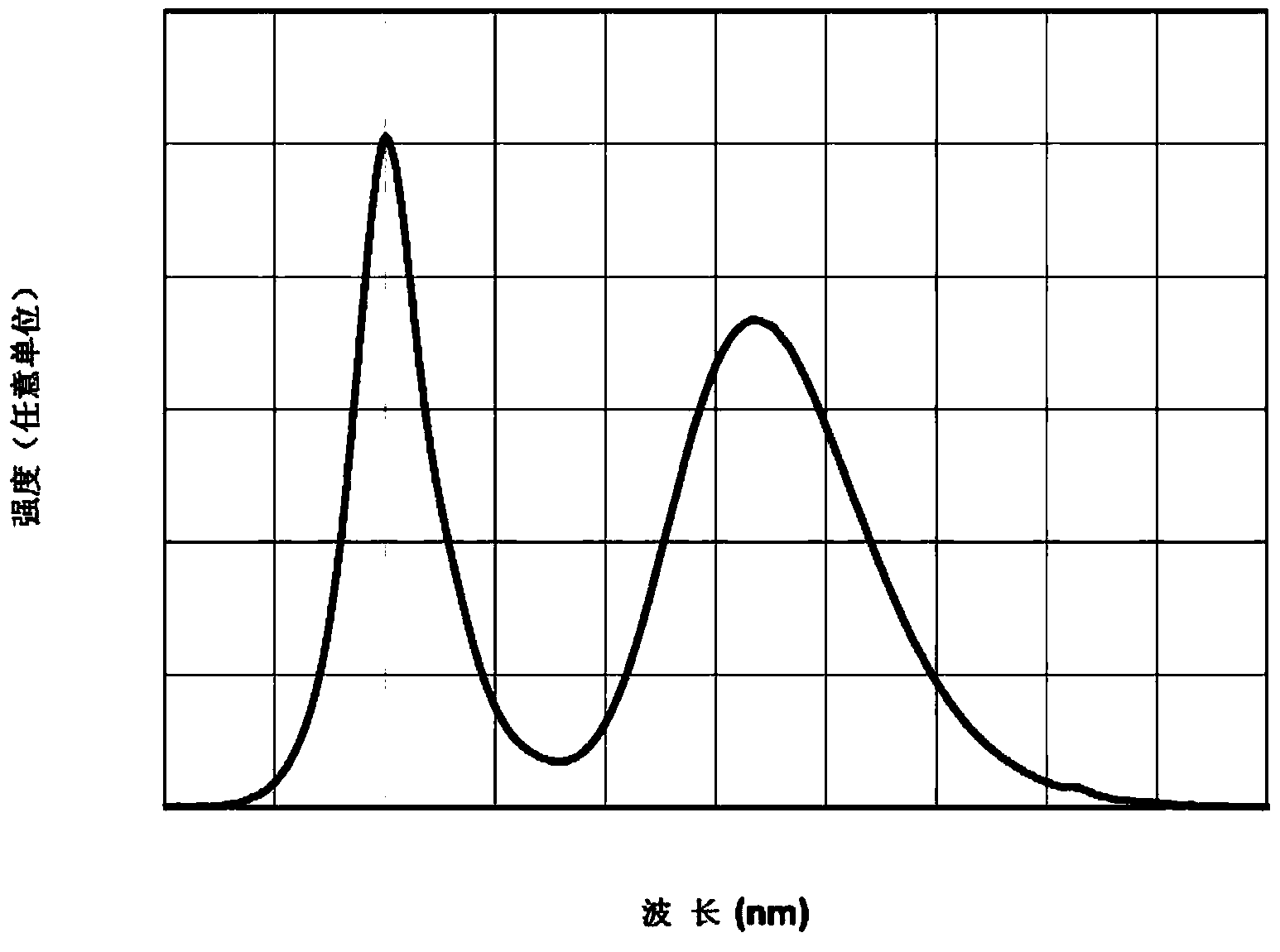

Light emitting devices with mixed phosphors

InactiveUS20060082288A1Using phosphorDischarge tube luminescnet screensElectroluminescent light sourcesPhosphorActivator (phosphor)

The invention provides compositions, which are mixtures of phosphors. The compositions comprise a first component described by the formula: M1SxSey:B1 and a second component that comprises a material described by the formula M2Am(SpSeq)n:B2, in which: M1 and M2 may be any metal species and B1 and B2 may be any activator, typically a metal species, with the remaining variables representing effective numerical values necessary for conferring electrical neutrality to the compositions. A phosphor mixture according to the invention is produced by first preparing individual components, and then physically mixing the components, as in a mortar or ball mill.

Owner:PHOSPHORTECH

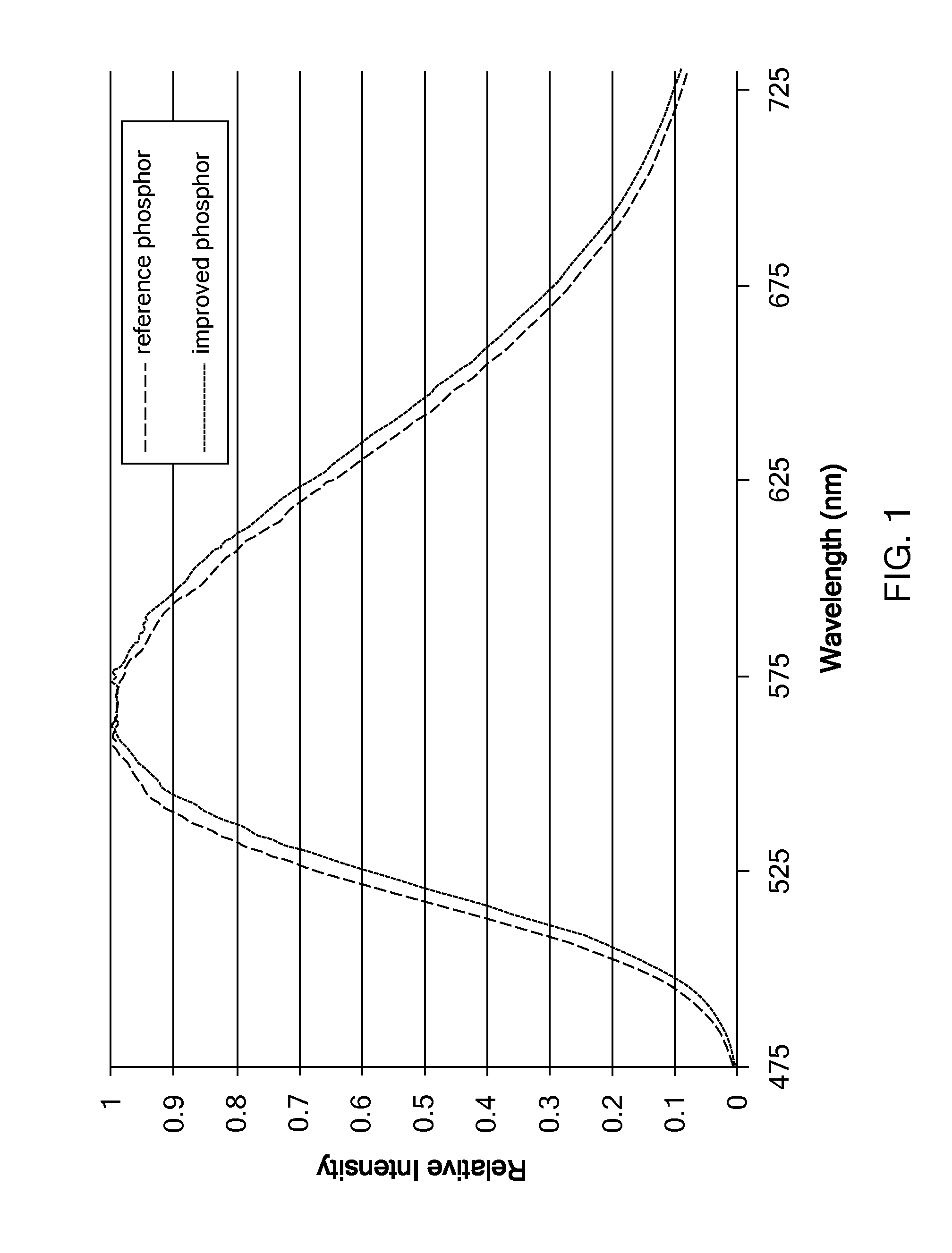

Yellow phosphor having an increased activator concentration and a method of making a yellow phosphor

ActiveUS20140167600A1Discharge tube luminescnet screensElectroluminescent light sourcesCrystallographyPhosphor

A yellow phosphor having an increased activator concentration includes a host lattice comprising yttrium aluminum garnet (YAG) and an activator comprising cerium in the host lattice, where the cerium is present at a concentration of at least about 5 wt. % Ce. A method of making a yellow phosphor includes forming a reaction mixture comprising: a first precursor comprising cerium and oxygen; a second precursor comprising cerium and fluorine; a third precursor comprising yttrium; and a fourth precursor comprising aluminum. The reaction mixture is heated in a reducing environment at a temperature sufficient to form a yellow phosphor including a host lattice comprising yttrium aluminum garnet and an activator comprising cerium (Ce) incorporated in the host lattice.

Owner:CREELED INC

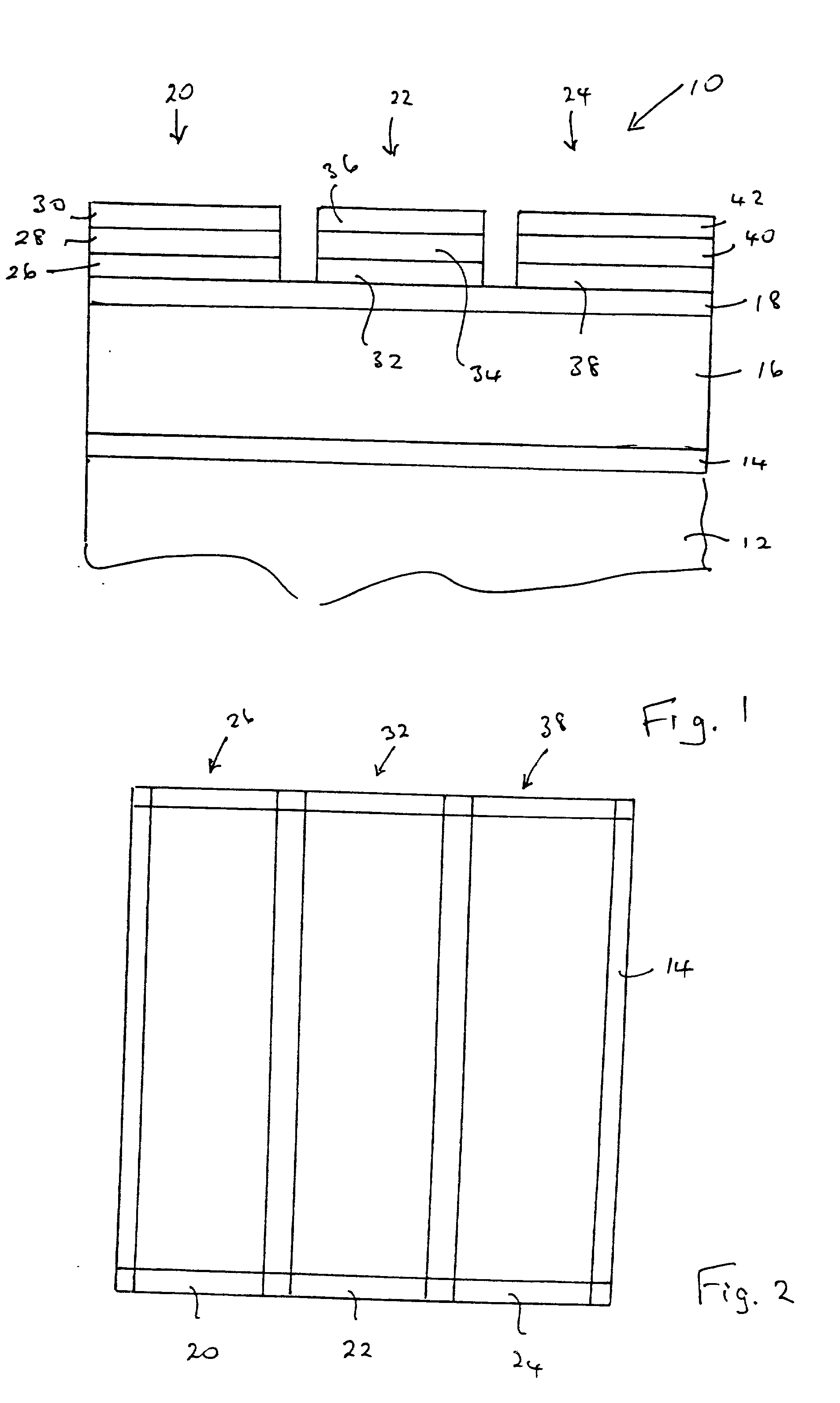

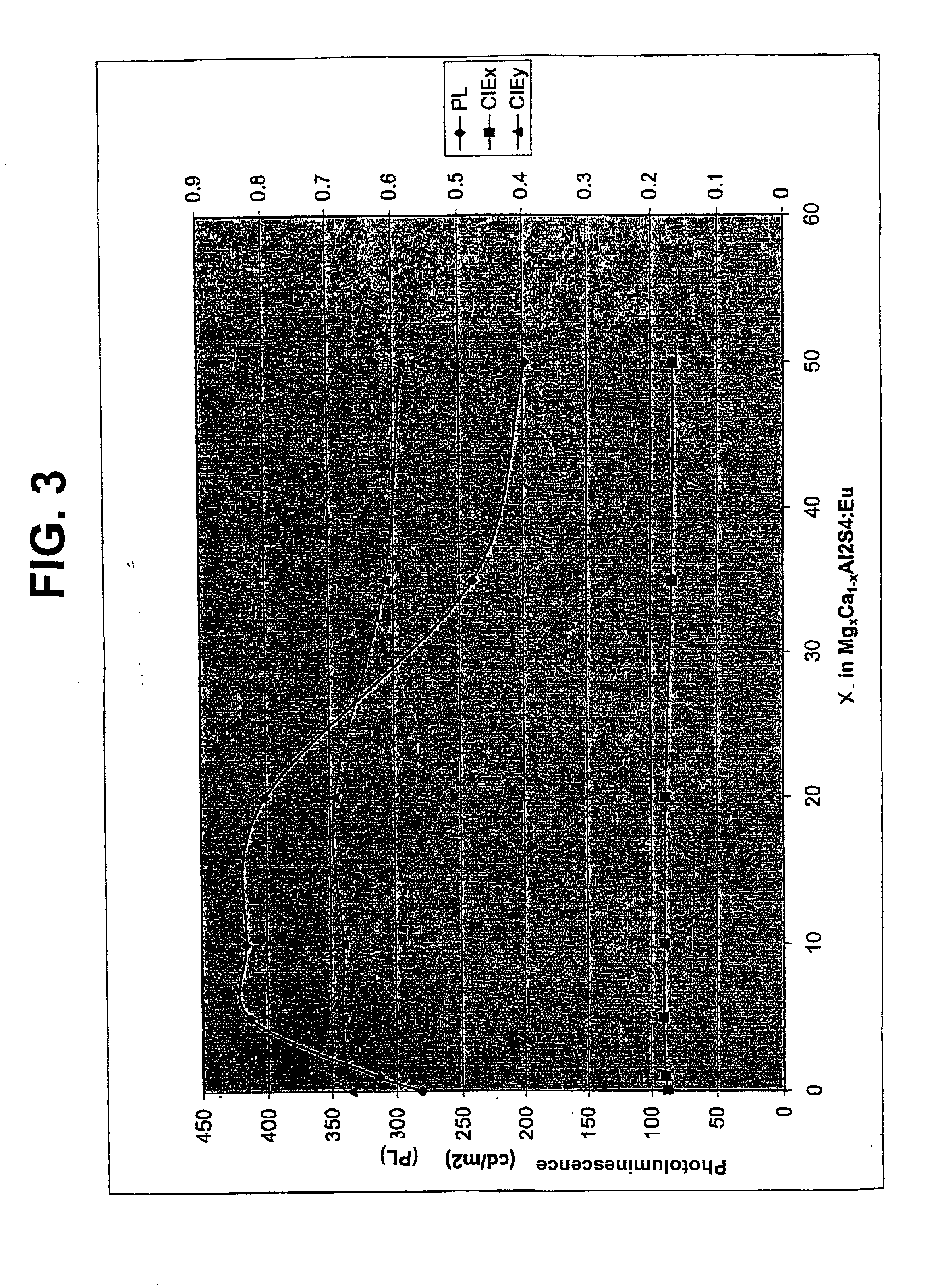

Magnesium calcium thioaluminate phosphor

InactiveUS20020192498A1Photomechanical apparatusSemiconductor/solid-state device manufacturingThio-Photoresist

A thin film phosphor for an electroluminescent device, and the electroluminescent device. The phosphor comprises a compound of the formula MgxCa1-xAl2S4:M, where the value of x is in the range 0<x<0.3 and M is a rare earth activator. Preferably, the value of x is in the range 0.05<x<0.20. A thin film phosphor for an electroluminescent device, the phosphor comprising magnesium calcium thioaluminate activated with a rare earth metal, the calcium thioaluminate containing an amount of magnesium to effect a lowering of the temperature of deposition of the phosphor on a substrate. A method for the preparation of the phosphor on a substrate, said method comprising the steps of: (i) depositing a mixtures of sulphides of magnesium, calcium, aluminum and rare earth metal on a substrate, and (ii) annealing the mixture of sulphides on the substrate so as to form the phosphor. The mixture of sulphides may be deposited on the substrate at a temperature of not greater than 200° C. Preferably, prior to step (i), a photoresist pattern is deposited on said substrate e.g. using photolithography.

Owner:IFIRE IP CORP

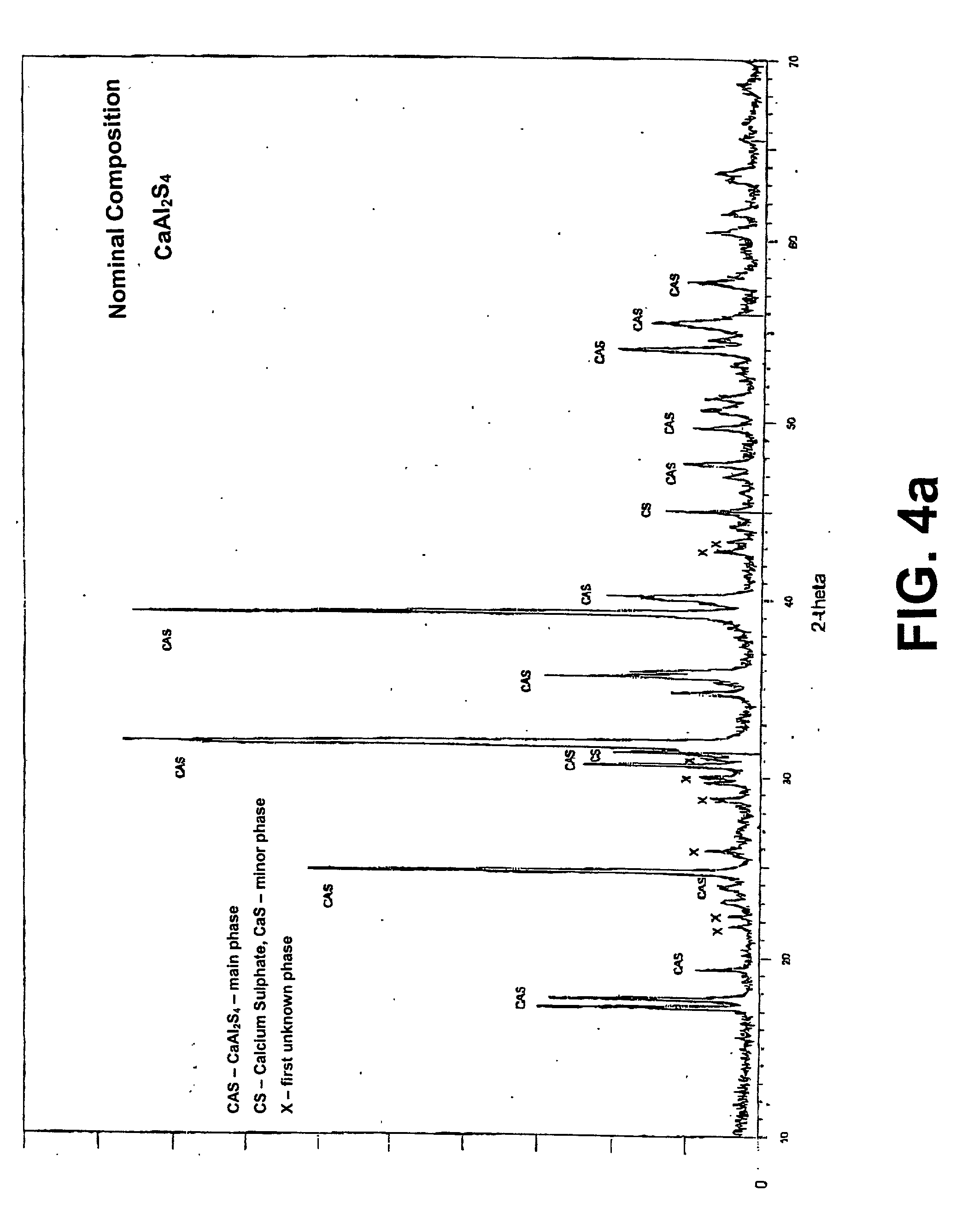

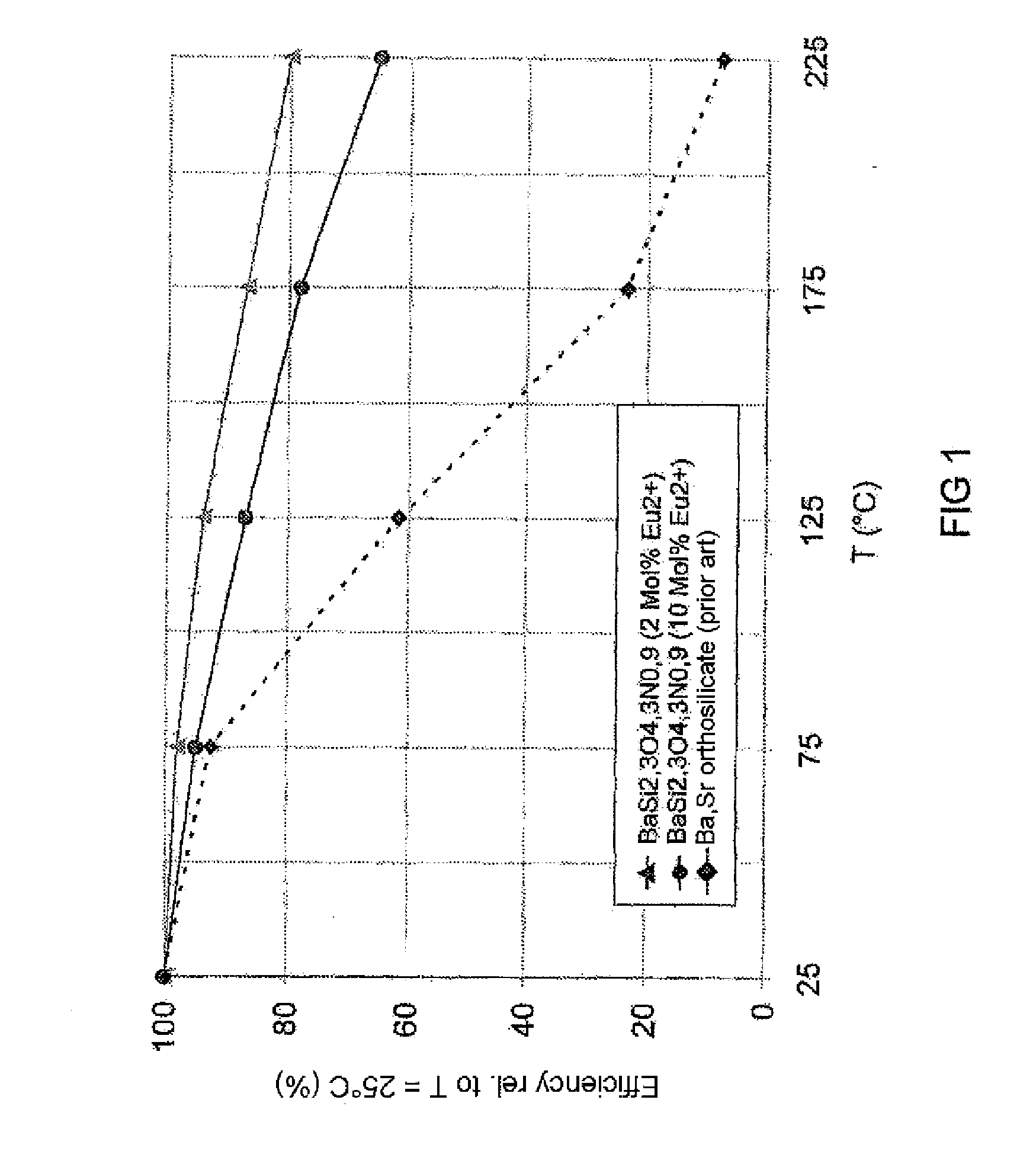

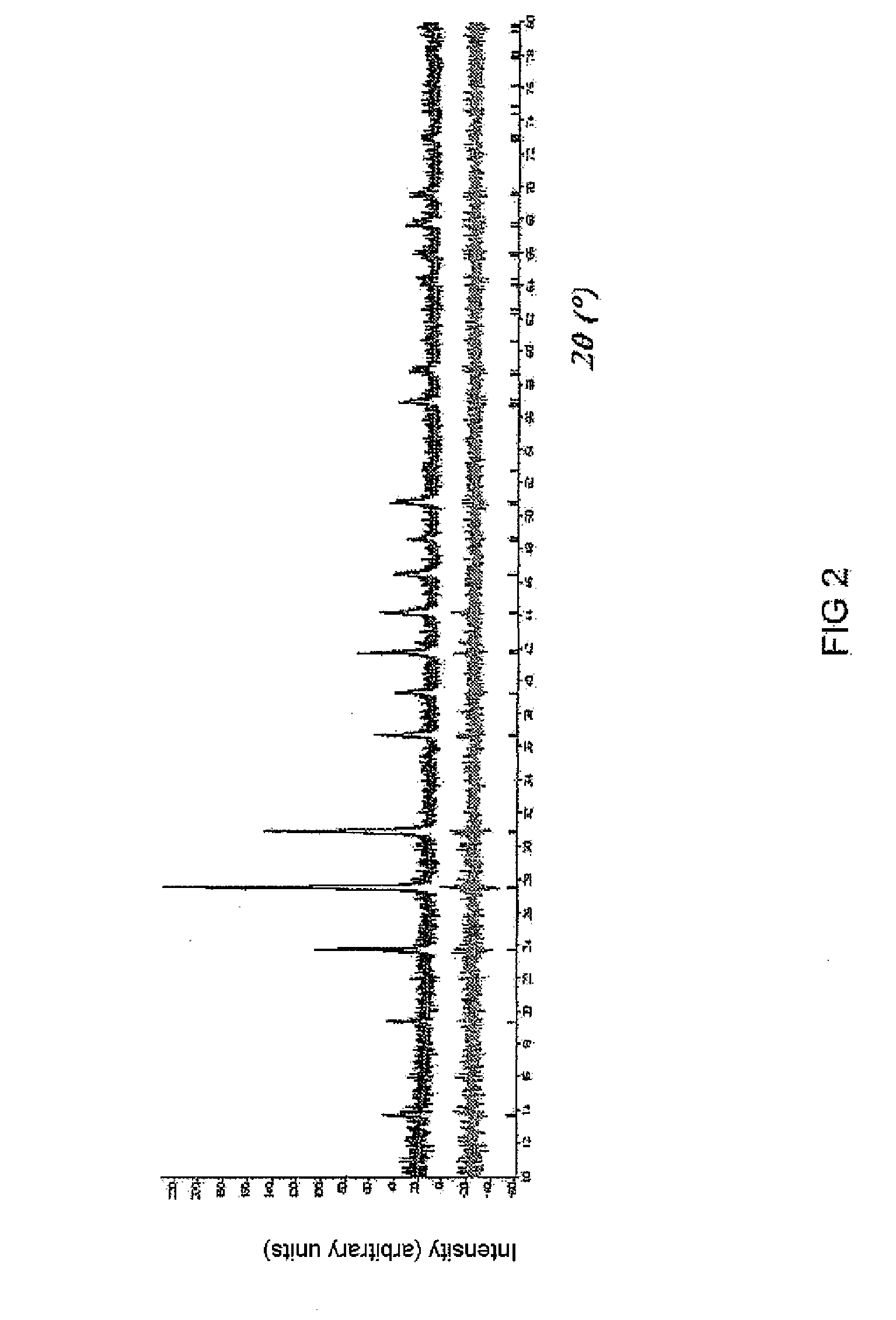

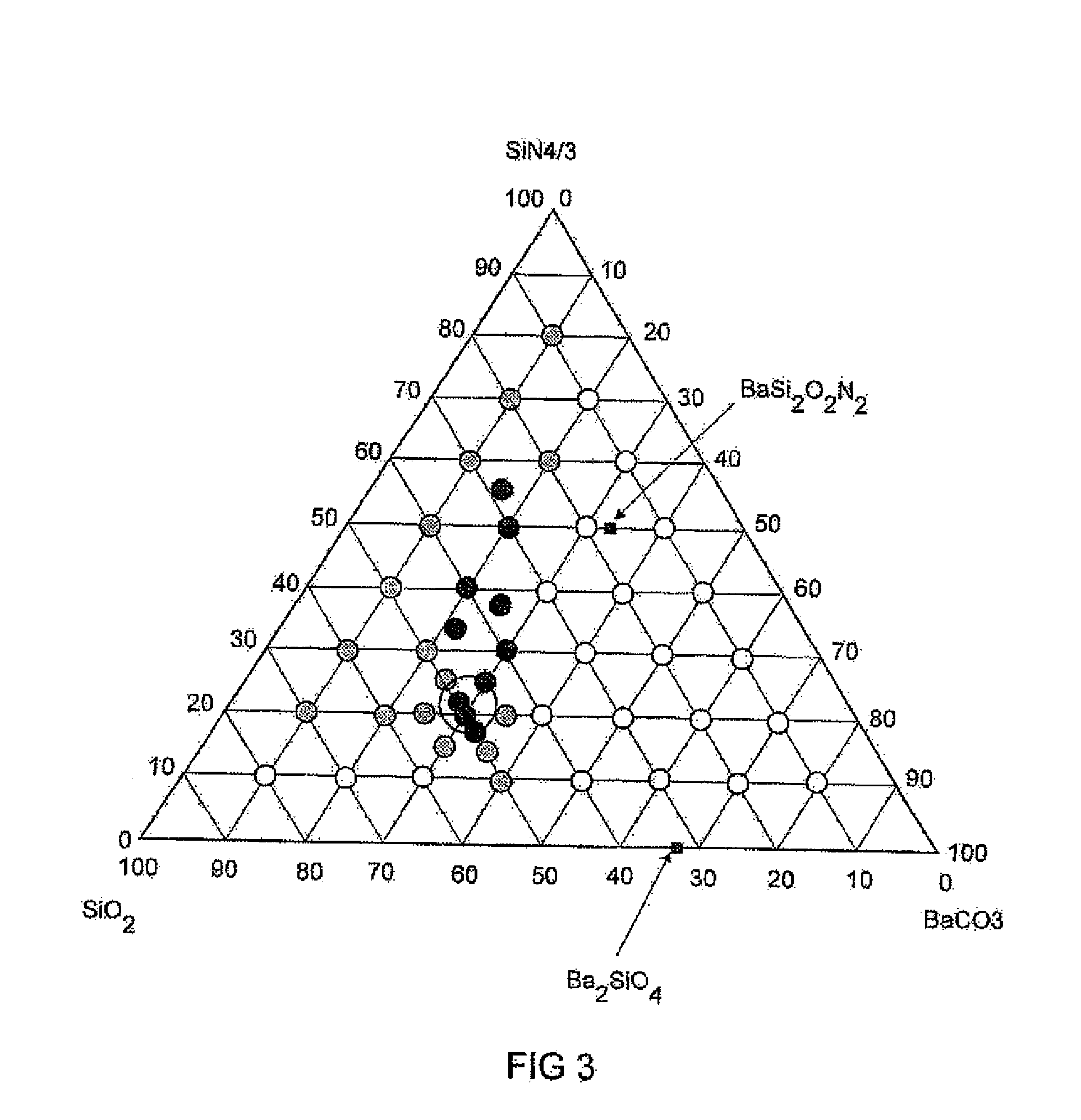

Temperature-Stable Oxynitride Phosphor and Light Source Comprising a Corresponding Phosphor Material

ActiveUS20110186778A1Improve thermal stabilityGood chemical stabilityDischarge tube luminescnet screensSolid-state devicesPhosphorOxygen content

A thermally stable phosphor made of the M-Si—O—N system, having a cation M and an activator D, M being represented by Ba or Sr alone or as a mixture and optionally also being combined with at least one other element from the group Ca, Mg, Zn, Cu. The phosphor is activated with Eu or Ce or Tb alone or as a mixture, optionally in codoping with Mn or Yb. The activator D partially replaces the cation M. The phosphor is produced from the charge stoichiometry MO—SiO2—SiN4 / 3 with an increased oxygen content relative to the known phosphor MSi2O2N2:D, where MO is an oxidic compound.

Owner:OSRAM OLED

Phosphor, manufacturing method of phosphor sheet and phosphor, and light emitting device using the phosphor

ActiveUS8303847B2Excellent emission efficiency and emission intensity/luminanceBroad emission spectrumDischarge tube luminescnet screensCathode ray tubes/electron beam tubesFluorescenceUltraviolet

Owner:NICHIA CORP +1

Novel Long Decay Phosphors

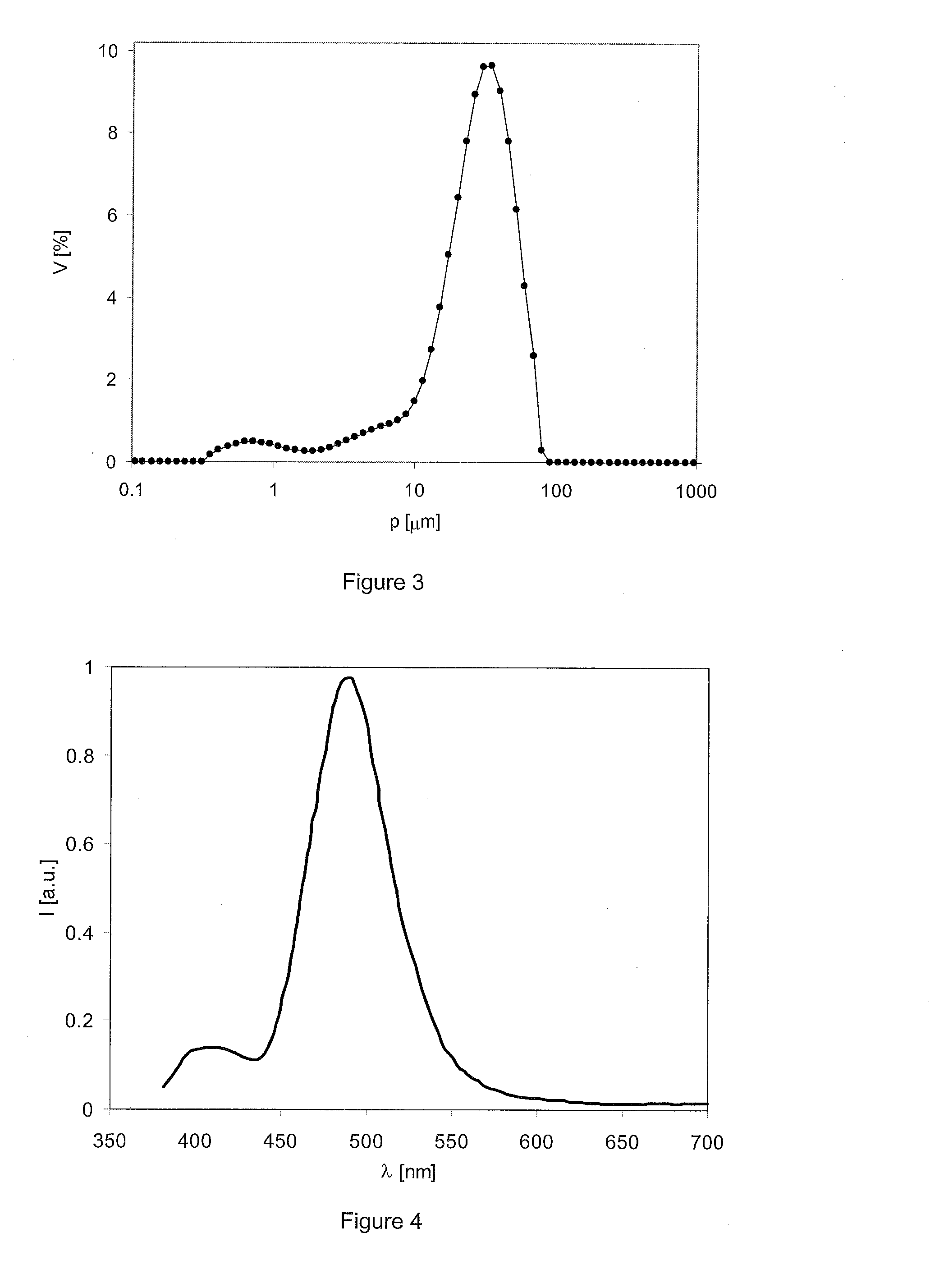

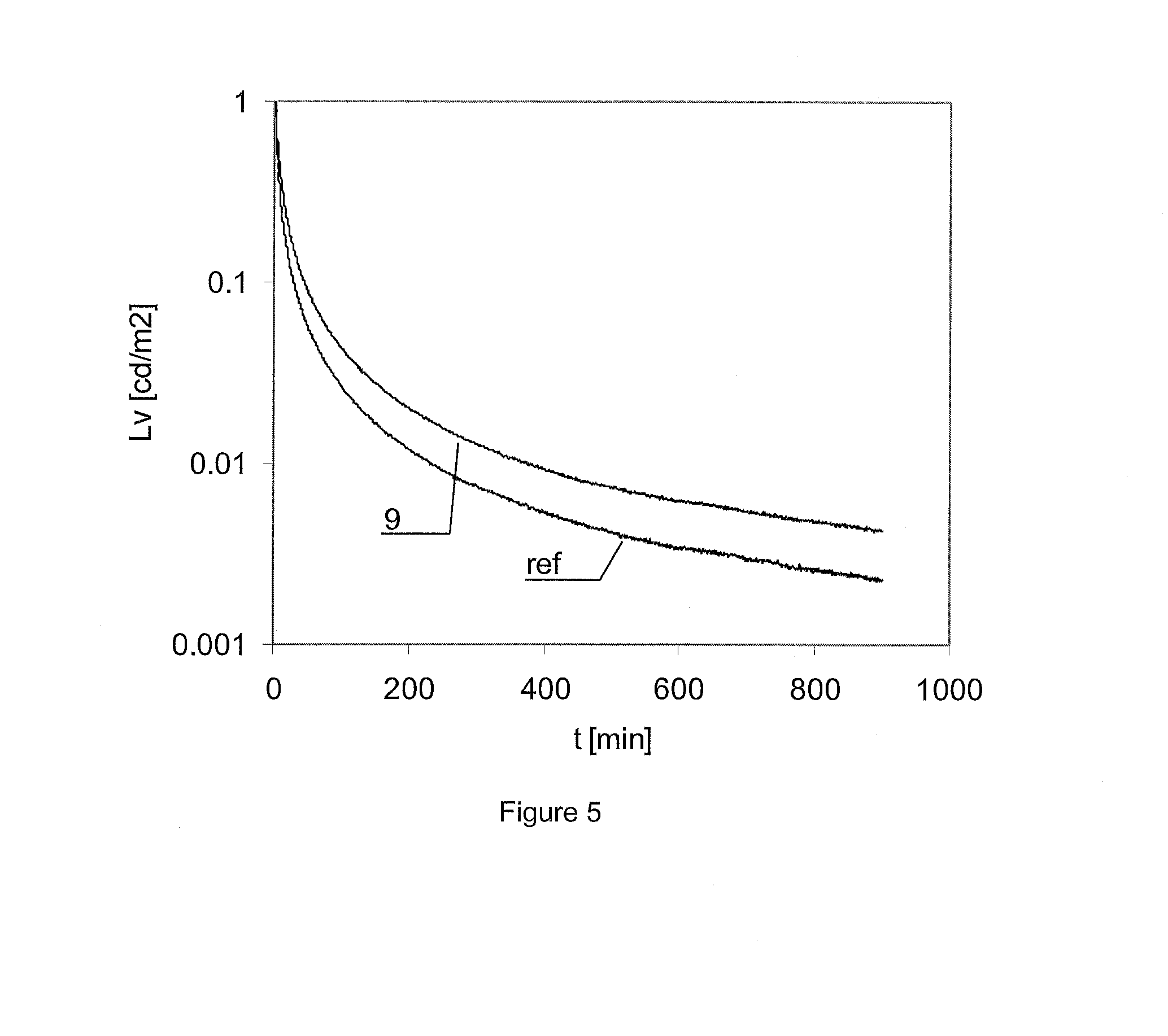

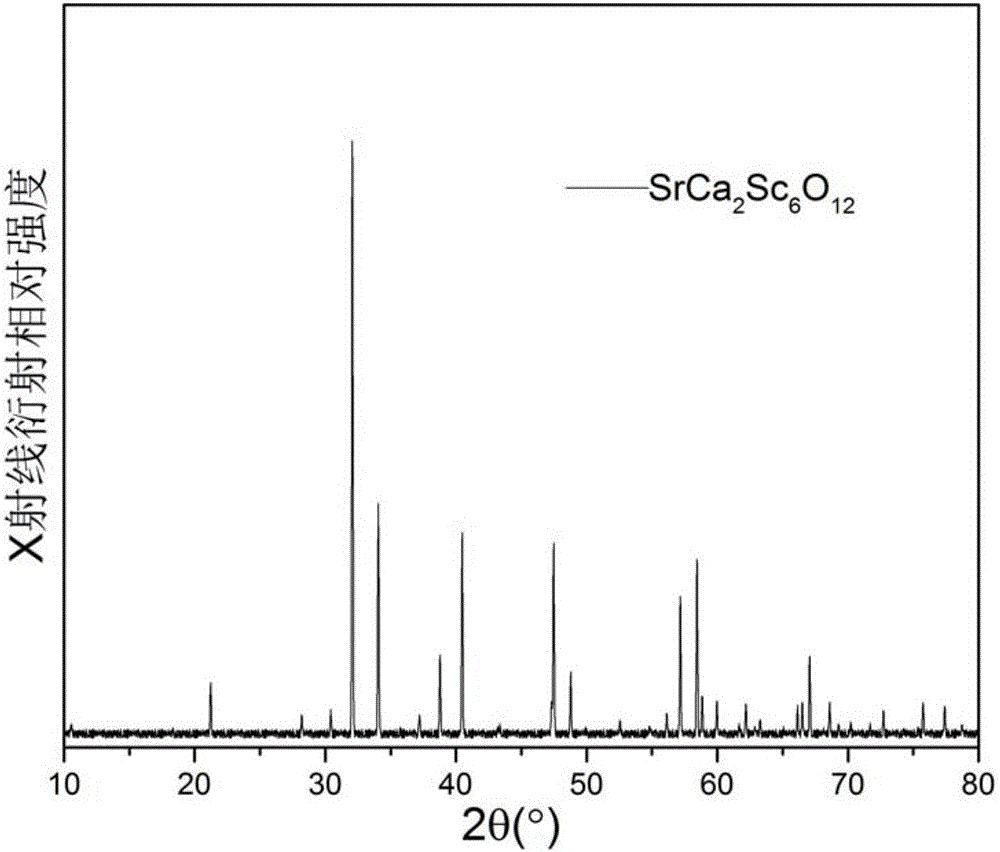

The present invention relates to long decay phosphors comprising rare earth activated strontium aluminates and methods for producing them. The phosphors comprise a matrix of the formula Sr4Al14O25 comprising europium as an activator and a further rare earth element as a co-activator, wherein the molar ratio of Al / Sr in the starting materials is in the range of 3.1 to less than 3.5 and the ratio of Eu / Sr is in the range of 0.0015 to 0.01. The process for the preparation of a phosphor comprises the steps of milling the starting materials for the synthesis of the phosphor, the starting materials comprising a boron compound selected from boric acid, boric oxide or a borate salt in an amount such that the B / Sr molar ratio is between 0.1 and to 0.3, treating the milled composition with heat, grinding the block material which is obtained through the heat treatment, ball-milling the crushed material, sieving the material, and washing the material with an aqueous solution.

Owner:ROLEX SA

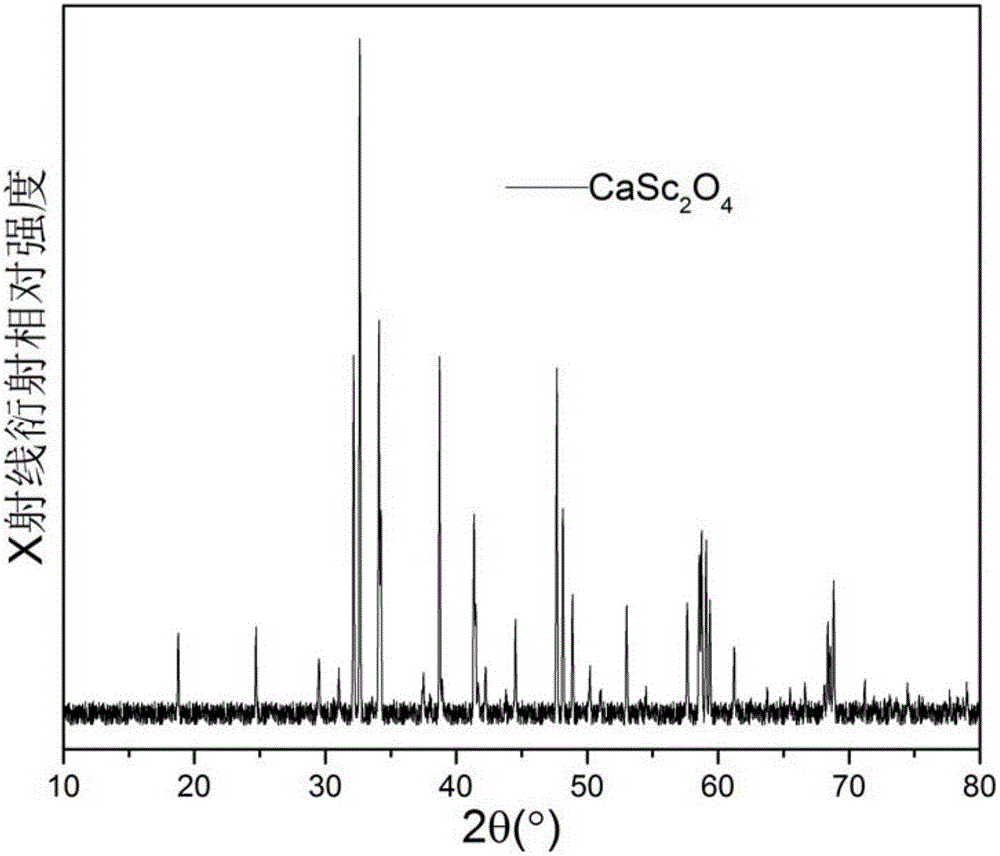

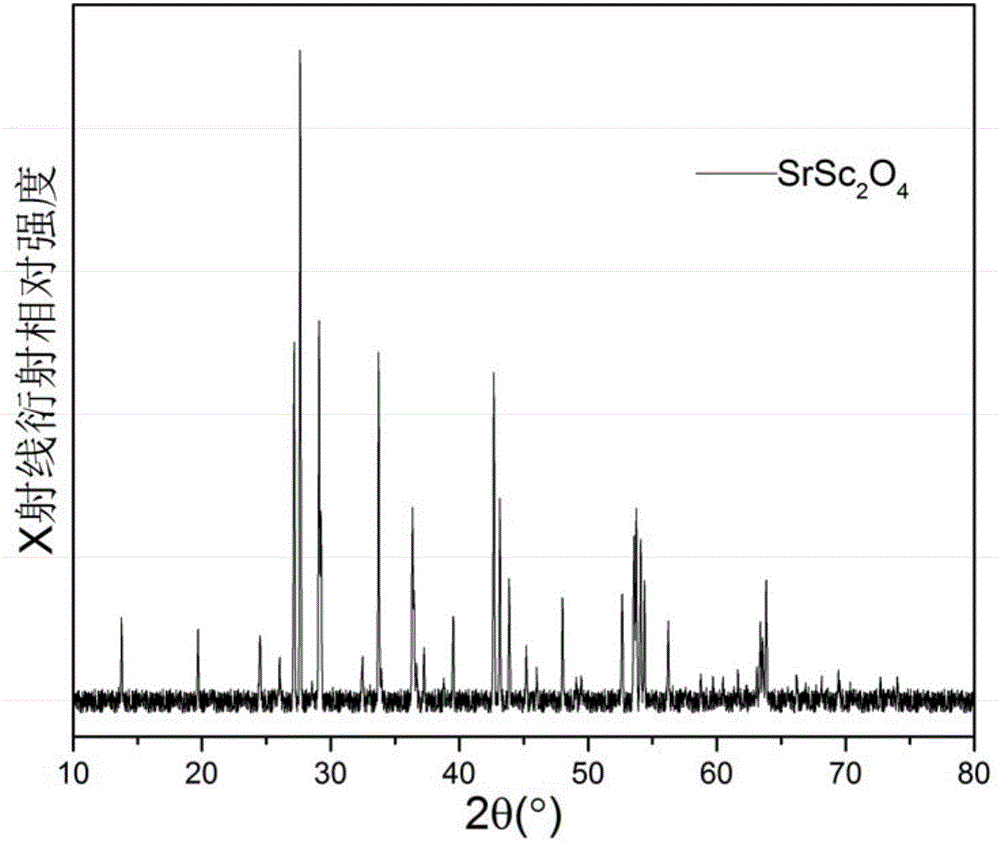

Scandate green phosphor and preparation method thereof

InactiveCN105820817AHigh color renderingGood colorLuminescent compositionsSemiconductor devicesChemical compositionPhosphor

The invention discloses scandate green phosphor and a preparation method thereof, and belongs to the technical field of light emitting materials. The chemical formula of the scandate green phosphor is Sr1-2xCexDxXa2Sx6O12; in the formula, x is greater than 0 and less than 0.5; D is at least one of Li, Na and the like. The preparation method of the scandate green phosphor comprises the following steps: mixing an Sr precursor, a Ce precursor, a D precursor, a Ca precursor and an Sc precursor, and performing high-temperature solid-phase reaction, thereby obtaining the scandate green phosphor of which the chemical formula is Sr1-2xCexDxXa2Sx6O12. The scandate green phosphor has completely novel chemical composition, Ce<3+> is taken as an activator, and the phosphor can be activated by ultraviolet light and violet-blue light to emit green light, so that the ultraviolet light can be converted into green light through the fluorescent material, then the fluorescent material can be used in a yellow fluorescent powder converted white light LED, and the color rendering property of the LED can be improved.

Owner:XIAMEN UNIV

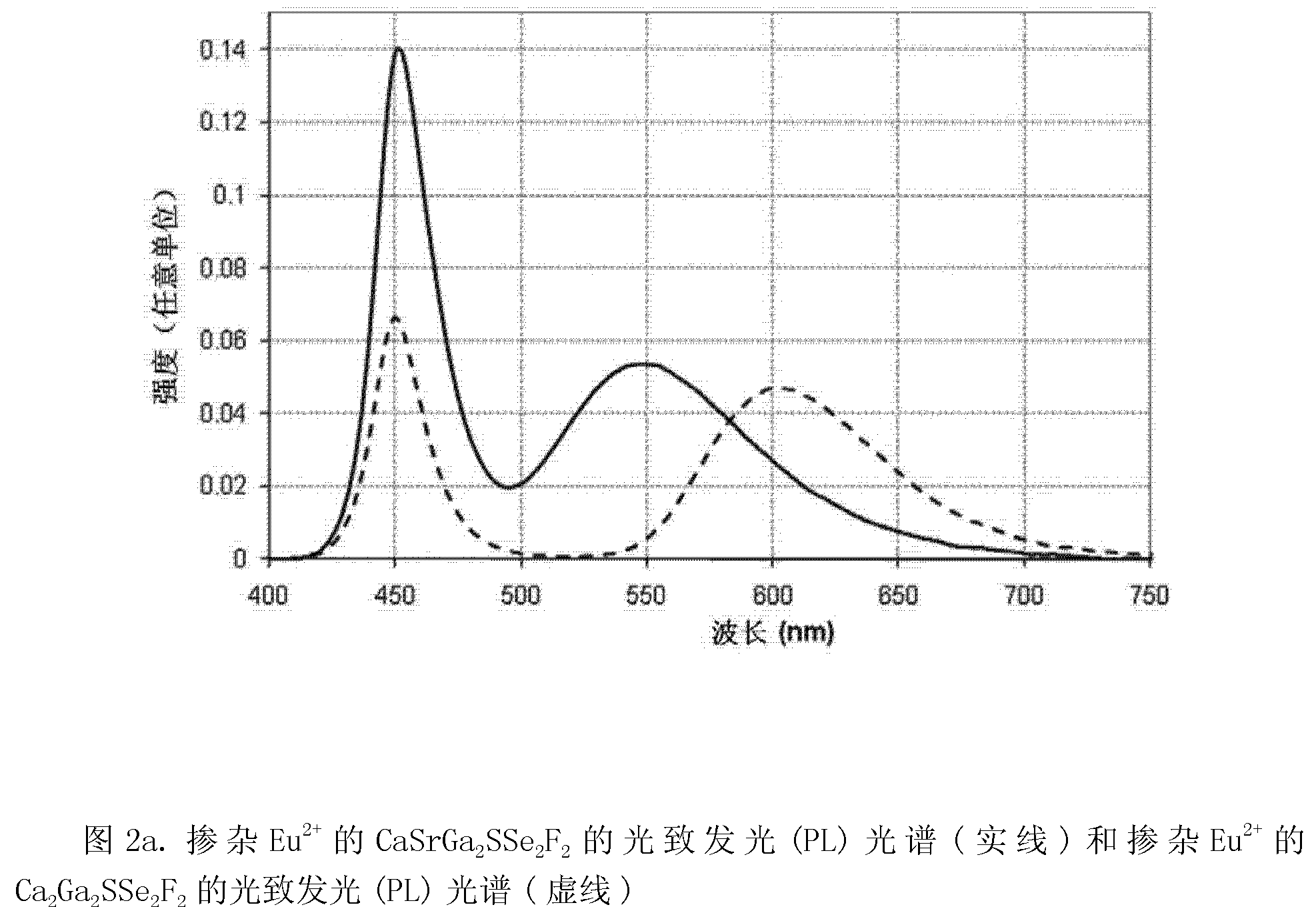

Phosphors of rare earth and transition metal doped Ca1+xSr1-xGayIn2-ySzSe3-zF2, methods of manufacturing and applications

InactiveCN104334683AEasy to understandElectrical apparatusElectroluminescent light sourcesMischmetalActive agent

Energy down conversion phosphors represented by the chemical formula Ca1+xSr1−xGayIn2−ySzSe3−zF2 where (0≰x≰1, 0≰y≰2, 0≰z≰3) doped with rare earth and / or transition metal elements is disclosed. Dopant impurities may be one or more species such as Eu, Ce, Mn, Ru, and / or mixtures thereof present as activators. The molar fractions x, y and z, the dopant species and the dopant concentration may be varied to tune the peak emission wavelength and / or the width of the emission peak.

Owner:AUTERRA INC

Phosphor and plasma display panel using the same

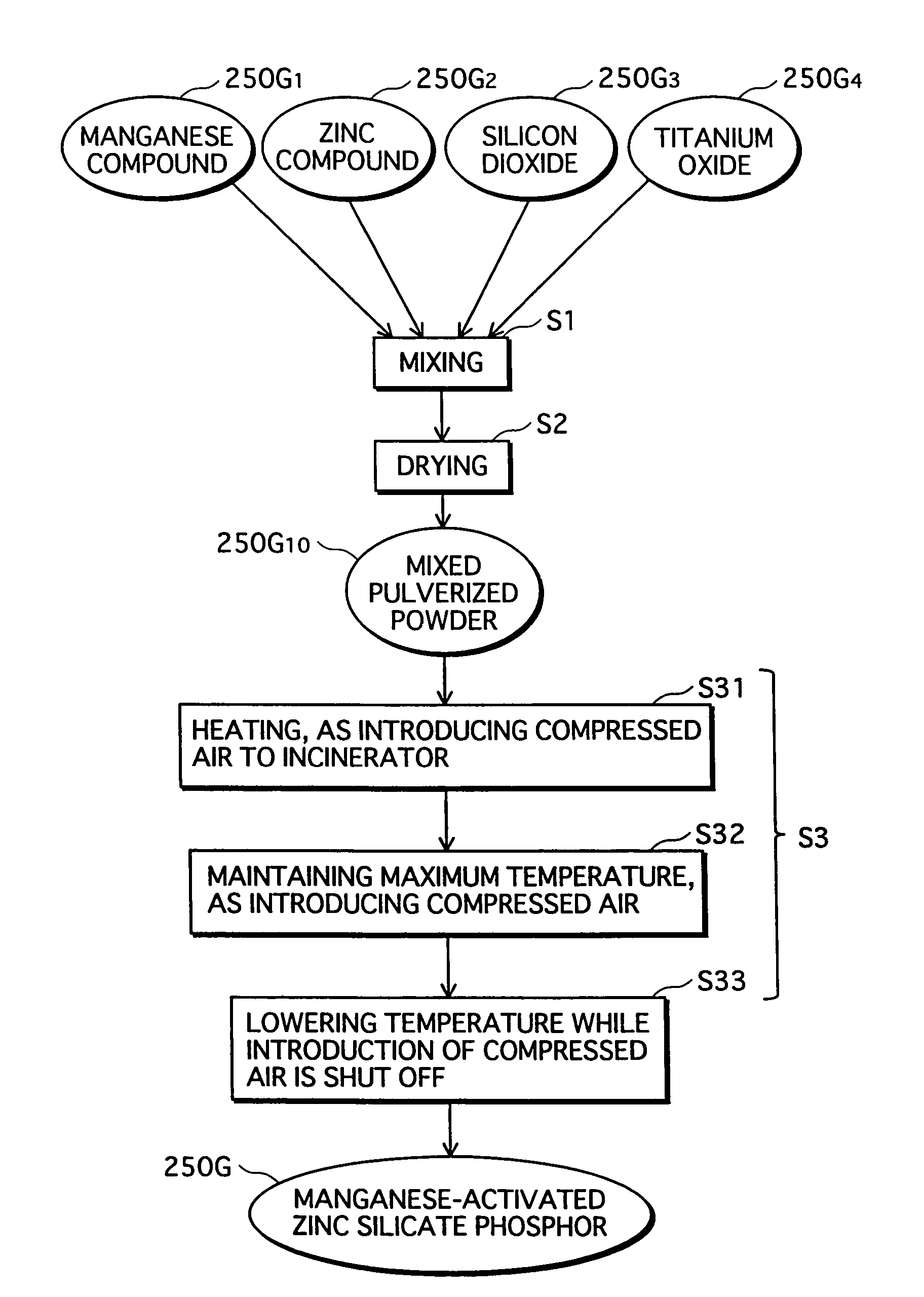

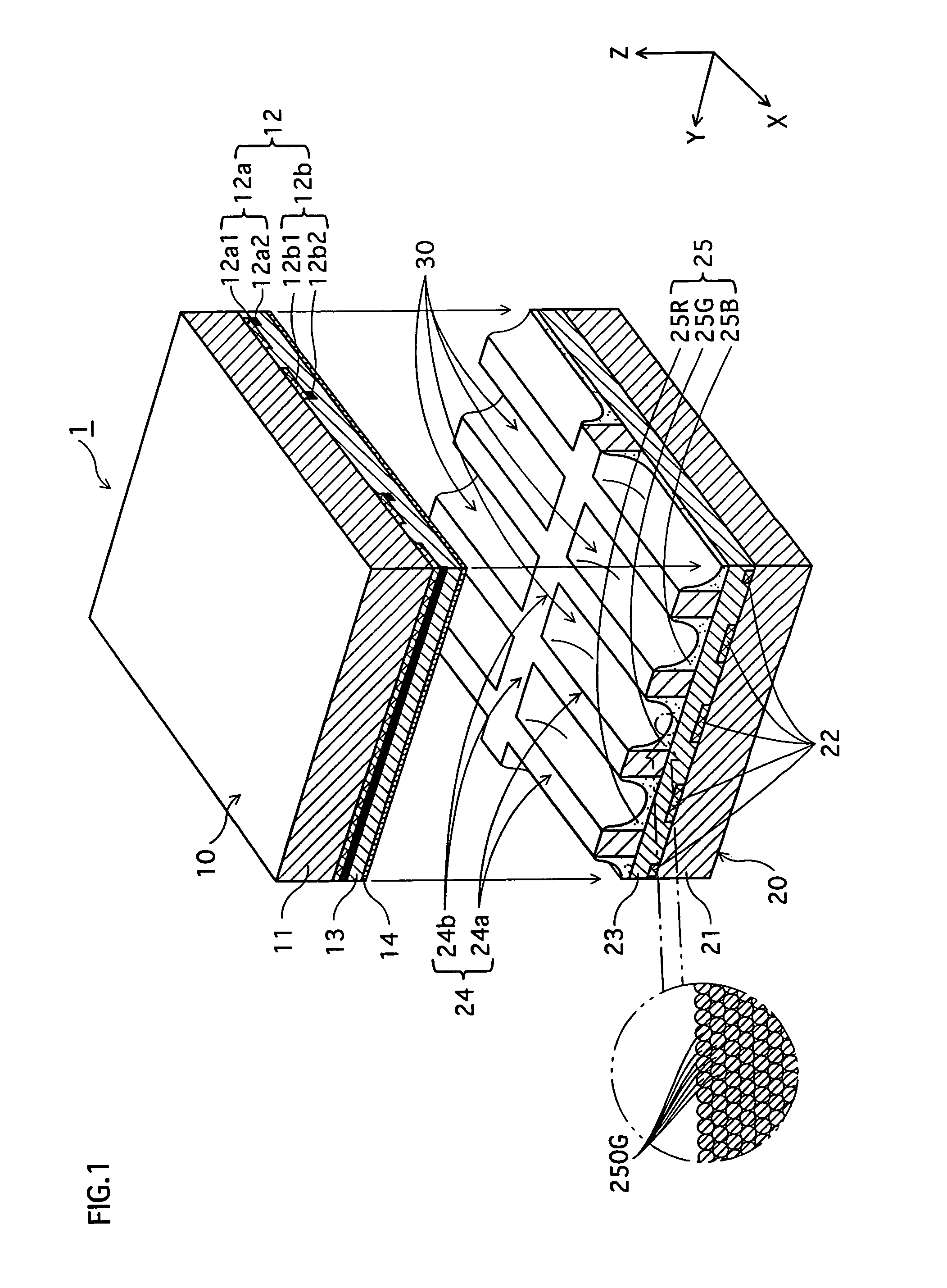

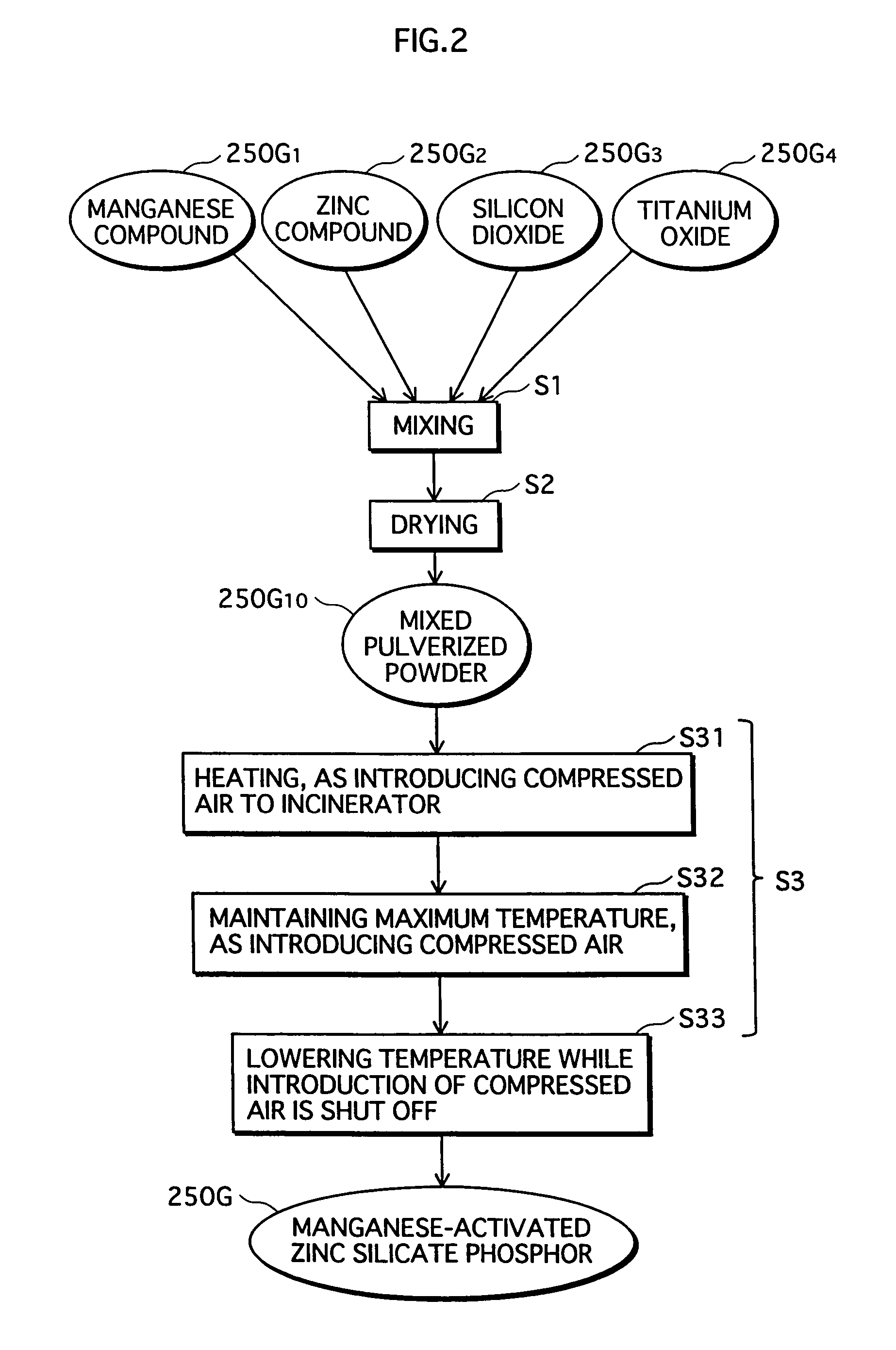

InactiveUS7465413B2Improve luminous brightnessImprove the immunityDischarge tube luminescnet screensLamp detailsPhosphorManganese

A phosphor of the present invention is characterized by: having a phosphor main portion containing zinc silicate as a base material and manganese as an activator; and having at least one element from among titanium (Ti), zirconium (Zr), and hafnium (Hf), or having at least one element from among molybdenum (Mo) and tungsten (W), added to the phosphor main portion. The phosphor with such a composition is capable of precisely controlling the composition of a surface region (i.e. the surface including the vicinity) of each phosphor particle and improving the crystallinity, which leads to a high luminous efficiency and a reduction in time-lapse degradation.

Owner:PANASONIC CORP

Phosphor, Method for Manufacturing Same, and Particle Dispersed El Device Using Same

InactiveUS20080057343A1Increase light intensityImprove conductivityMaterial nanotechnologyElectrical apparatusElectrical conductorPhosphor

An EL phosphor contains a conductor phase including carbon nanotubes, carbon nanohorns, or another carbon component. The phosphor includes a sulfide that has Ag— or Cu-activated ZnS as a main component thereof. The phosphor includes material expressed by the general formula Zn(1−x)AxS:Ag / Cu, D (where A is at least one type of group 2A element selected from the group consisting of Be, Mg, Ca, Sr, and Ba; D is a coactivator and is at least one element selected from the group consisting of group 3B or group 7B elements; and 0≦x<1), or an amorphous oxynitride phosphor comprising B—N—O, Si—O—N, Al—O—N, Ga—O—N, Al—Ga—O—N, In—Ga—O—N, or In—Al—O—N, which are activated by Eu2+, Gd3+, Yb2+, or another earth metal ion.

Owner:SUMITOMO ELECTRIC IND LTD

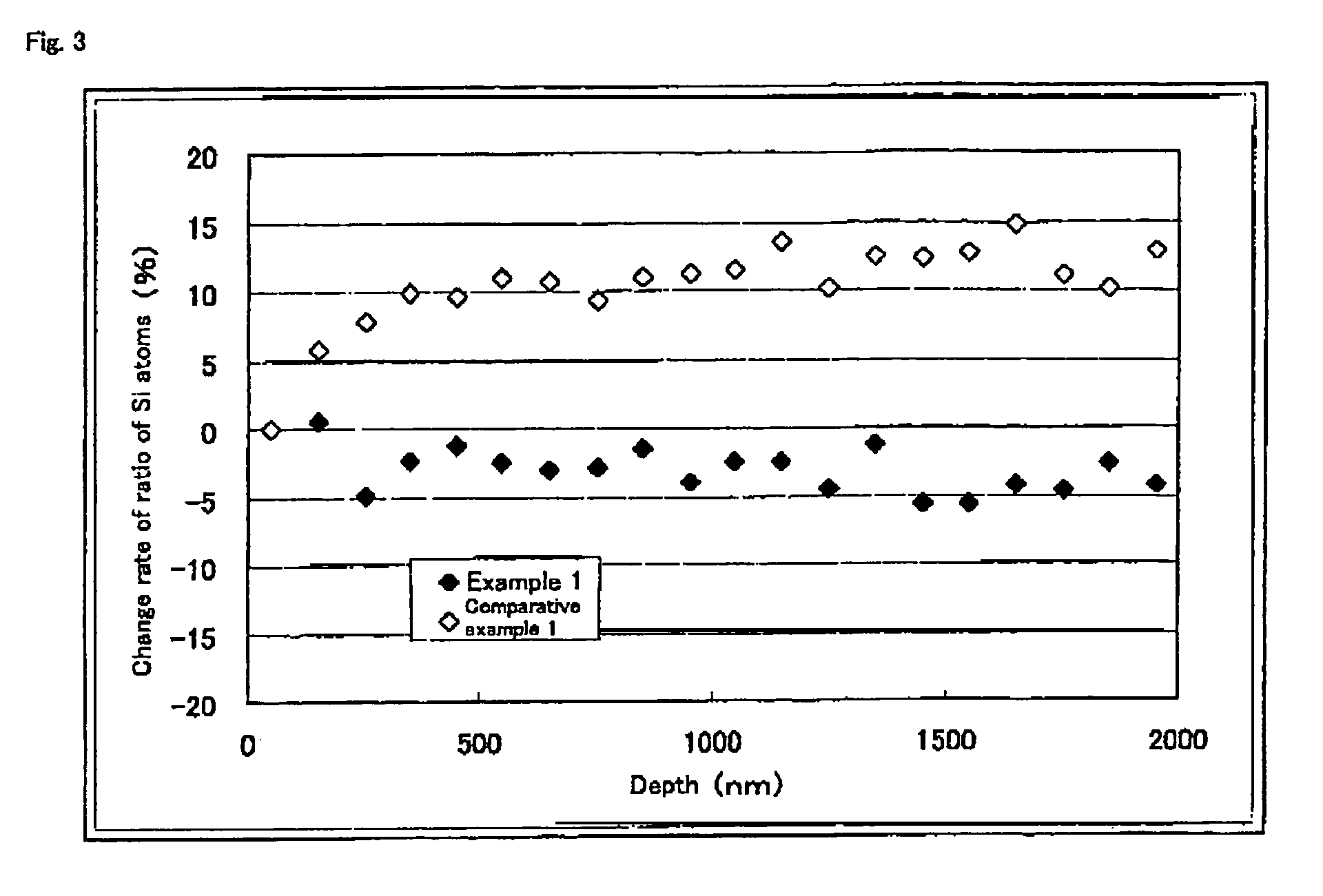

Homogeneous incorporation of activator element in a storage phosphor

ActiveUS20050132951A1Apparent advantageEasy to manufacturePolycrystalline material growthX-ray/infra-red processesCrystallographyDopant

A method has been disclosed for manufacturing a storage phosphor for use in a photostimulable phosphor screen or panel comprising a support and a storage phosphor layer, wherein a dopant or activator is incorporated more homogeneously in amorphous and in crystalline phosphors as well, starting with a mixing step of said matrix component and activator component in stoechiometric ratios in order to provide a desired phosphor composition; and more particularly in order to prepare a CsBr:Eu2+phosphor having an optimized sensitivity with respect to its particle size.

Owner:AGFA NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com