Phosphors of rare earth and transition metal doped Ca1+xSr1-xGayIn2-ySzSe3-zF2, methods of manufacturing and applications

一种ca1.5sr0.5ga2s3f2、过渡金属元素的技术,应用在光子能降频转换应用领域,能够解决波长转换效率低、荧光粉吸收弱等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

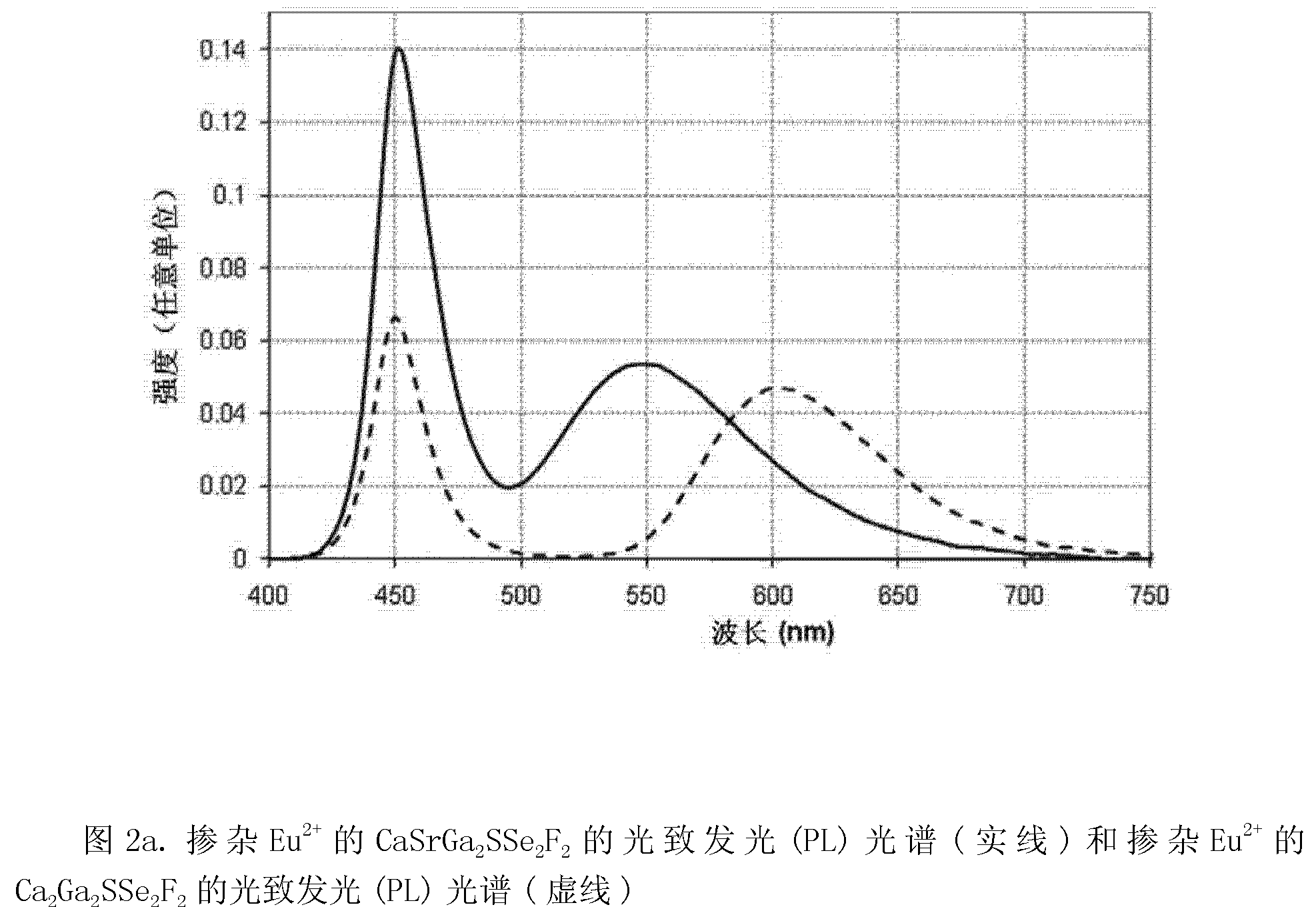

[0047] Doped with Eu 2+ CaSrGa 2 SSe 2 f 2 Through pre-synthesized SrSe, GaSe, GaS, CaF 2 , and EuCl 3 synthesized by reaction. Each compound (SrSe, GaSe, GaS, CaF 2 ) are 1 mole. EuCl 3 The weight is 4% of the total weight of other compounds. The mixture was reacted at a temperature of 1000° C. for 2 hours in an argon atmosphere. Obtains a yellow-green glowing ingot. The ingot was rolled to a fine powder and annealed at 850° C. for an additional 30 minutes in a hydrogen atmosphere to obtain a yellow-green luminescent free-flowing powder. The powder was chemically washed in an aqueous solution containing KOH (pH in the range of 9 to 10) and then dried with nitrogen. Figure 2a The photoluminescence spectrum of the phosphor is shown in (solid line). The powder X-ray diffraction pattern (XRD) of the phosphor is illustrated in FIG. 3 . The electro-to-optical conversion efficiency of the PC-LED fabricated using the dry powder and excited by a blue LED (451 nm) was meas...

Embodiment 2

[0049] To demonstrate the peak emission tunability of the inventive alloy composition according to the element ratio, doping Eu 2+ Ca 2 Ga 2 SSe 2 f 2 By pre-synthesized CaS, GaSe, CaF 2 and EuCl 3 The opposite reaction is synthesized. CaS and CaF 2 Each compound is 1 mole. GaSe is 2 moles. EuCl 3 The weight is 4% of the total weight of other compounds. The mixture was reacted at a temperature of 1000° C. for 2 hours in an argon atmosphere. Obtains a yellow-orange glowing ingot. The ingot was rolled into a fine powder and annealed at 850° C. for an additional 30 minutes in a hydrogen atmosphere to obtain a yellow-orange glowing free-flowing powder. The powder was chemically washed in an aqueous solution containing KOH (pH in the range of 9 to 10) and then dried with nitrogen. Figure 2a The photoluminescence spectrum of the phosphor is shown in (dashed line).

Embodiment 3

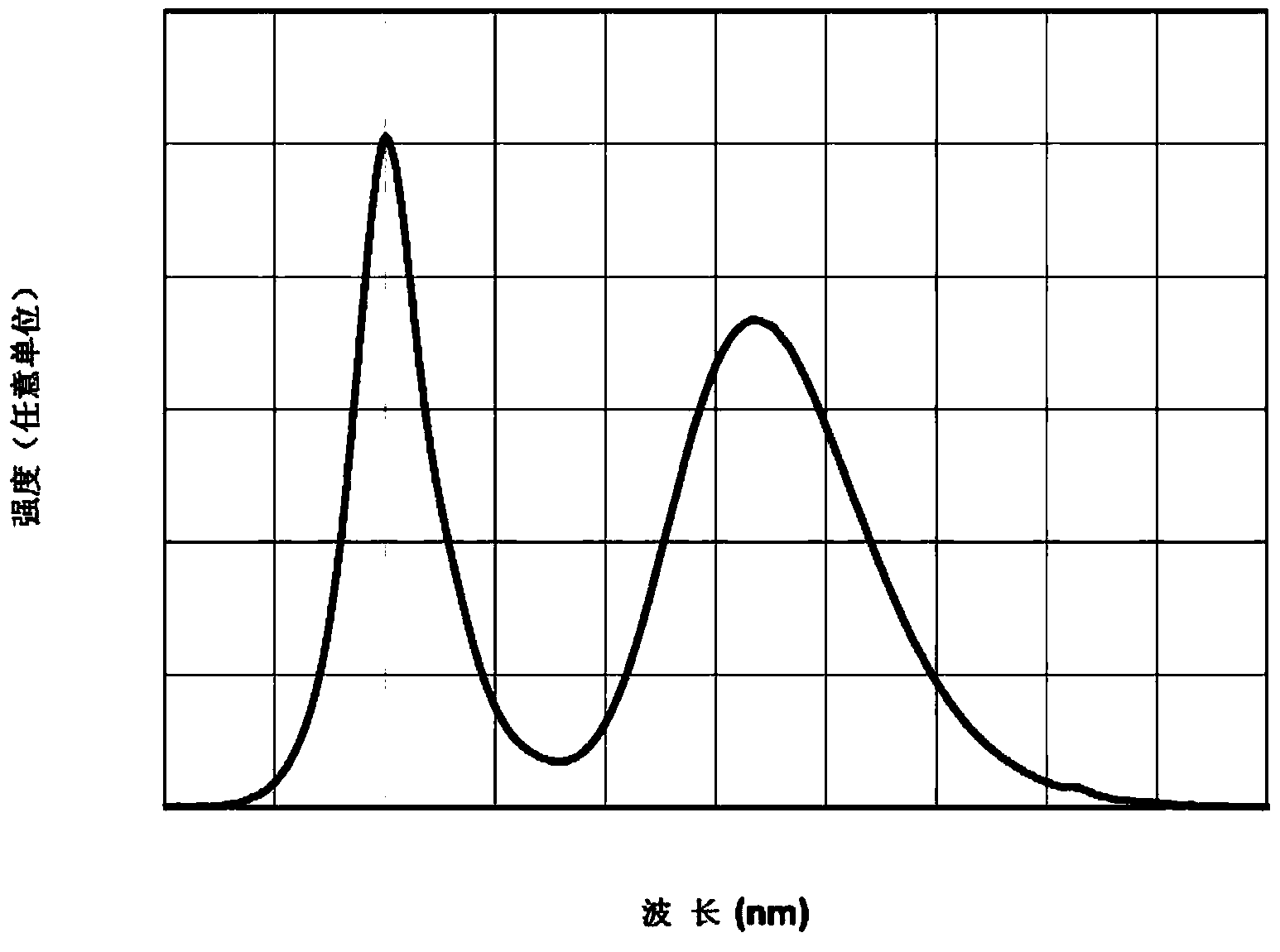

[0051] Doped with Eu 2+ CaSrGa 2 S 3 f 2 Via pre-synthesized SrS:Eu 2+ , GaS and CaF 2 The opposite reaction is synthesized. SrS:Eu 2+ and CaF 2 Each is 1 mole, and GaS is 8 moles (excess). Eu 2+ The weight of is 2% of the total weight of SrS in the synthesized compound. The mixture was reacted at a temperature of 900° C. for 48 hours and then at 1050° C. for 12 hours in an argon atmosphere. The reaction mixture was slowly cooled to 950°C at a rate of 2°C per hour and then cooled to room temperature at a rate of 50°C per hour by a rapid cooling cycle. Green-emitting crystals embedded in an excess of GaS were obtained. The crystals were extracted by washing the reaction mixture with KOH-containing aqueous solution (pH in the range of 10-11) for 12 hours. This extracted crystal was crushed into a fine powder and then annealed at 900 °C for 12 h in an argon atmosphere to obtain a green luminescent free-flowing powder. In Figure 2b it is shown that the photoluminescen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| surface pH | aaaaa | aaaaa |

| surface pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com