Rare earth nano silicate red phosphor and its preparation method

A nano-silicate, red fluorescence technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of decreased luminous intensity, large particles and complex processes, and achieve improved luminous intensity, stable optical performance, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

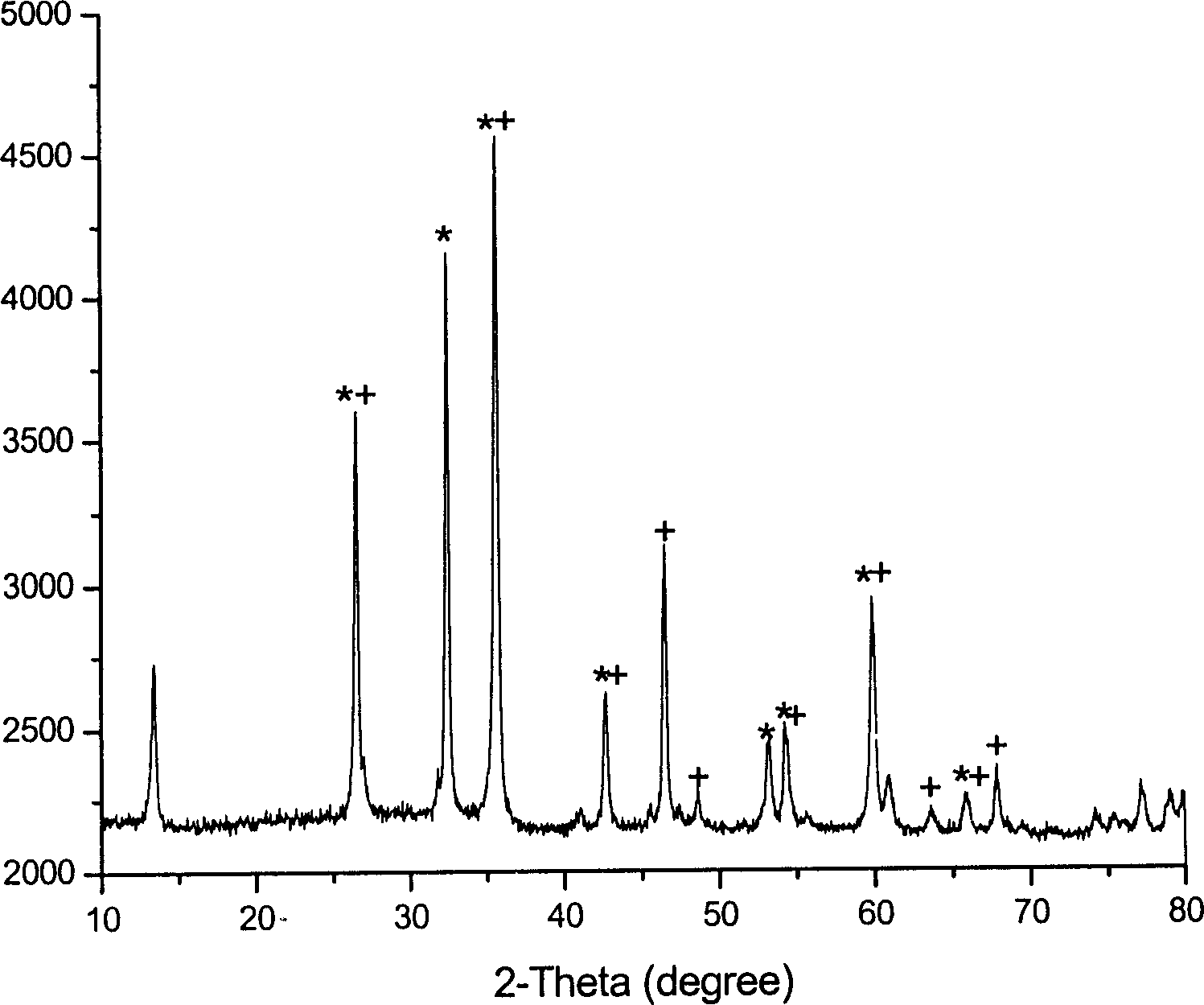

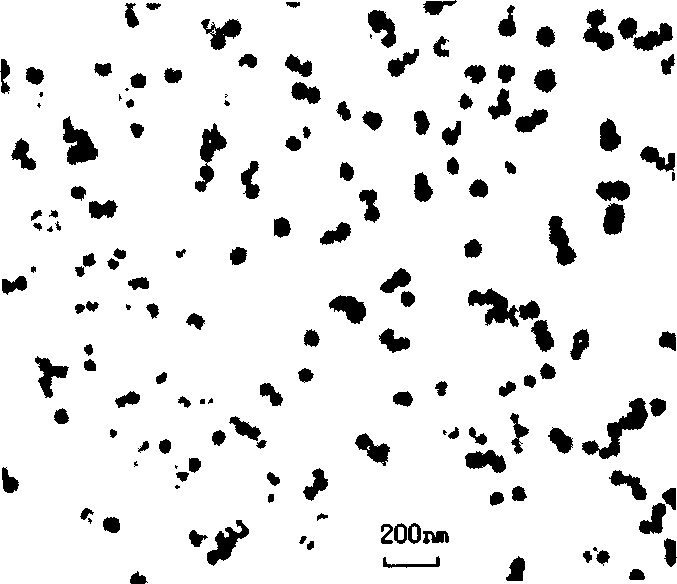

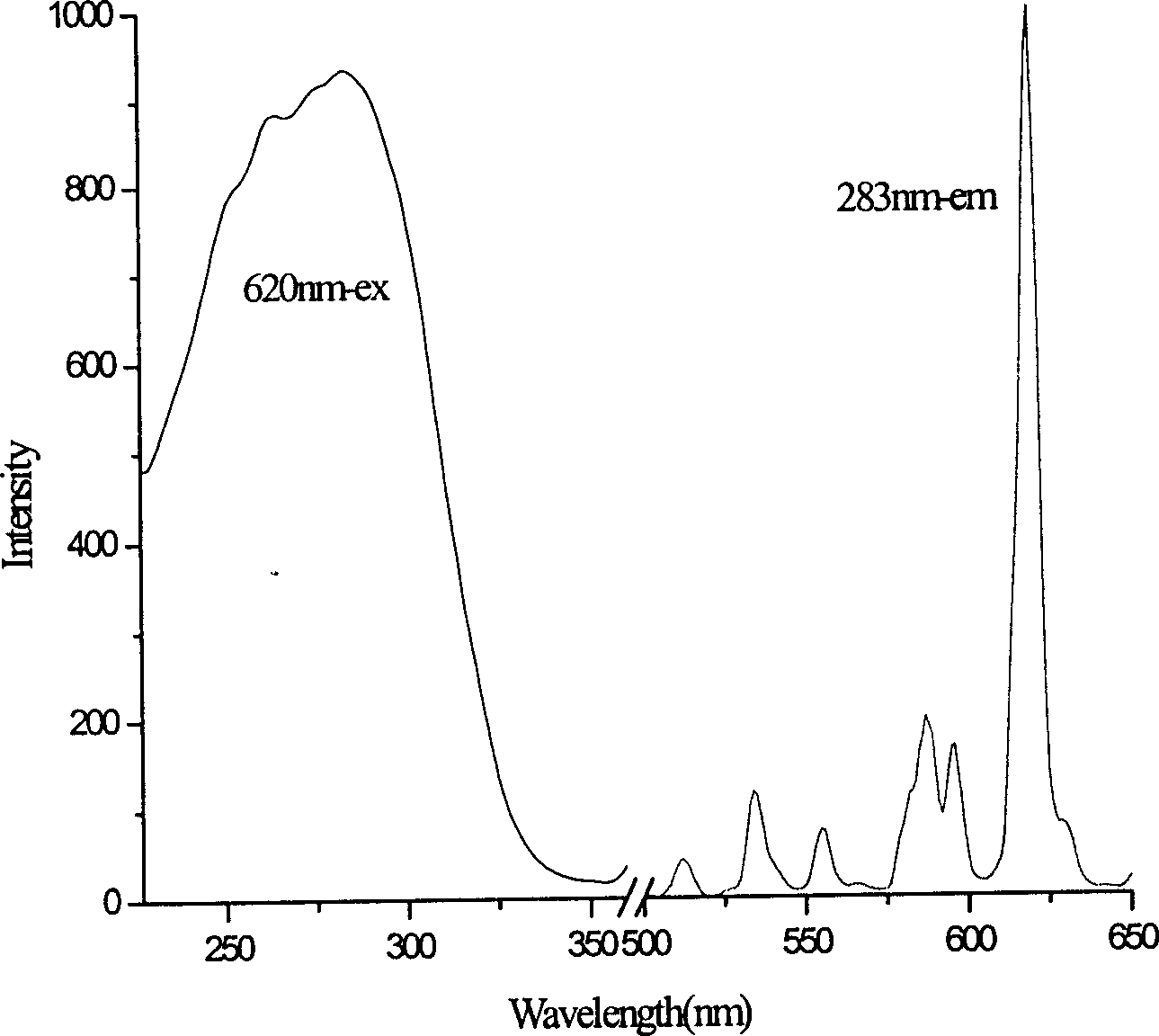

[0033] 3.77g Y 2 o 3 and 0.1056g Eu 2 o 3 Dissolve in 66% nitric acid under magnetic stirring, distill off water and excess nitric acid under reduced pressure at 70°C, then add 30ml ethanol and stir to obtain a clear and transparent solution, add 1.0g SiO 2 For airgel, stir magnetically at 65°C for 90 minutes to obtain a transparent sol, distill off ethanol under reduced pressure under stirring to obtain a powder solid, transfer it to a muffle furnace for sintering at 600°C for 3 hours to obtain the product. See XRD diagram figure 1 , in the figure, *β-Y 2 Si 2 o 7 : Eu (monoclinic center), +δ-Y 2 Si 2 o 7 : Eu (orthogonal primary), sample TEM picture see figure 2 , the excitation and emission spectra of the sample at 600°C are shown in image 3 . Detected by transmission electron microscope (Hitachi H-80), the average particle size of rare earth nano silicate red phosphor is about 60-80nm. With 60W xenon lamp as excitation source at room temperature, using VARAI...

Embodiment 2

[0035] 3.77g Y 2 o 3 and 0.1056g Eu 2 o 3 Dissolve in 37% hydrochloric acid under magnetic stirring, distill off water and excess hydrochloric acid at 70°C under reduced pressure, then add 30ml ethanol and stir to obtain a clear and transparent solution, add 1.0g SiO 2 For airgel, stir magnetically at 65°C for 90 minutes to obtain a transparent sol, distill off ethanol under reduced pressure under stirring to obtain a powder solid, transfer it to a muffle furnace for sintering at 600°C for 3 hours to obtain the product.

Embodiment 3

[0037] 3.77g Y 2 o 3 and 0.1056g Eu 2 o 3 Dissolve in 37% hydrochloric acid under magnetic stirring, distill off water and excess hydrochloric acid at 70°C under reduced pressure, then add 30ml ethanol and stir to obtain a clear and transparent solution, add 1.0g SiO 2 For airgel, stir magnetically at 65°C for 20 minutes, then ultrasonically disperse for 30 minutes, then stir magnetically at 65°C for 30 minutes to obtain a transparent sol, then distill ethanol under reduced pressure under stirring to obtain a powder solid, then transfer to a muffle furnace and sinter at 600°C for 3 hours to obtain the airgel. product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com