Organic electroluminescence device and preparation method thereof

An electroluminescence device and luminescence technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of poor refractive index, loss of total reflection, low light extraction performance, etc., and achieve stable luminous color, The effect of reducing the decay speed and reducing the potential barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

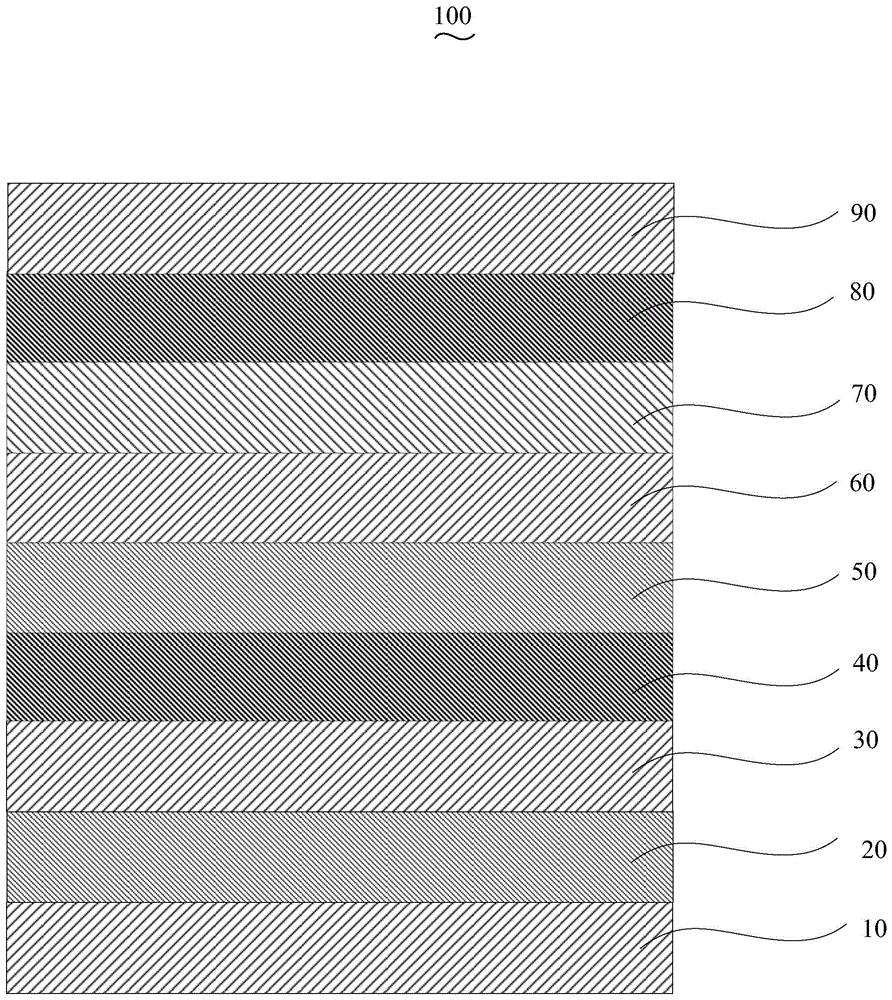

[0037] The preparation method of the organic electroluminescence device 100 of an embodiment, it comprises the following steps:

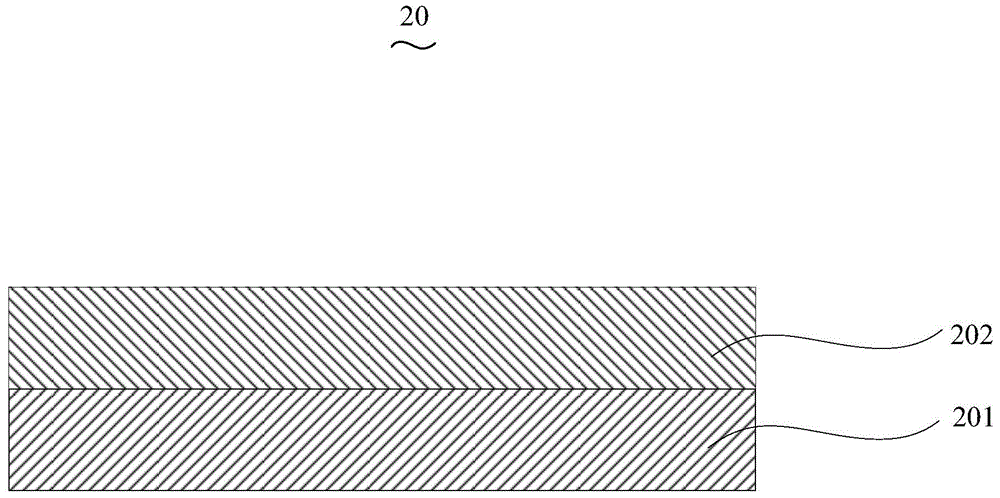

[0038] Step S110 , preparing the scattering layer 20 on the surface of the glass substrate 10 by electron beam evaporation.

[0039] The scattering layer 20 is formed on one side surface of the glass substrate 10 . The scattering layer 20 is composed of a luminescent material layer 201 and a binary doped layer 202. The luminescent material layer 201 is prepared on the surface of the glass substrate 10 by thermal resistance evaporation, and the material of the luminescent material layer 201 is selected from 4-(dinitrile Methyl)-2-butyl-6-(1,1,7,7-tetramethyljulonedine-9-vinyl)-4H-pyran (DCJTB), 9,10-di-β- Naphthalene anthracene (ADN), 4,4'-bis(9-ethyl-3-carbazolevinyl)-1,1'-biphenyl (BCzVBi) and 8-hydroxyquinoline aluminum (Alq 3 ), the binary doped layer 202 is prepared on the surface of the luminescent material layer 201 by electron beam evaporat...

Embodiment 1

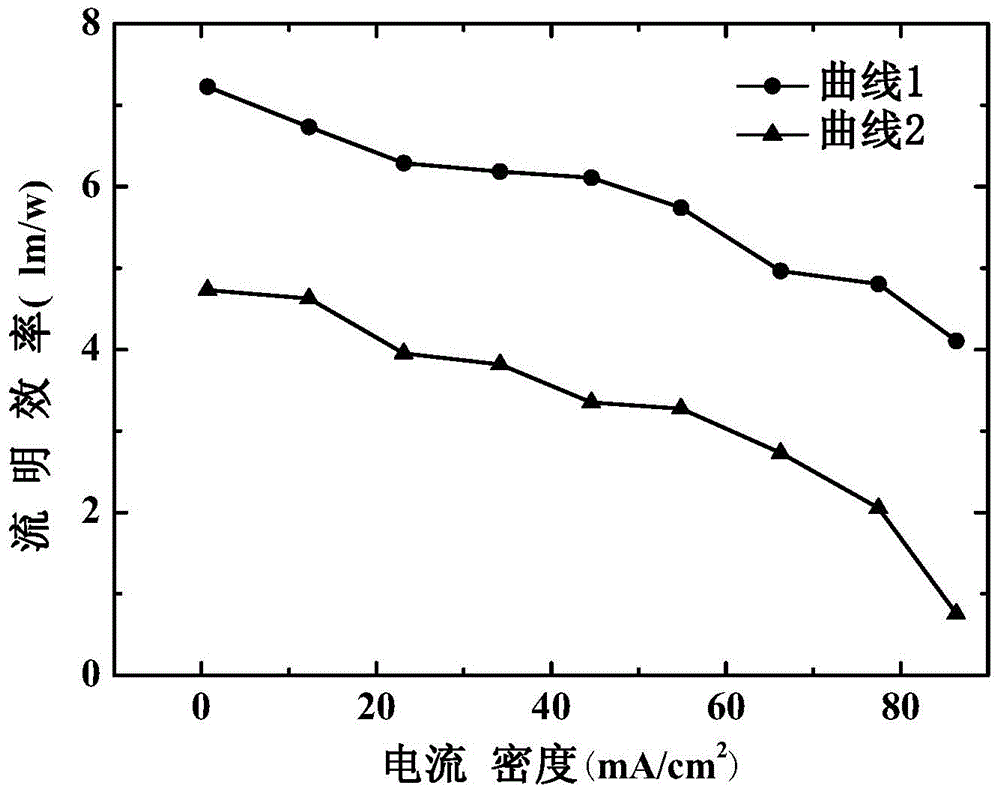

[0059] The structure prepared in this example is glass substrate / Alq 3 / CaO:Re 2 o 7 / ITO / MoO 3 / NPB / Alq 3 / TAZ / CsF / Ag organic electroluminescent device, in this embodiment and the following embodiments, " / " indicates a layer, and ":" indicates doping.

[0060] The glass substrate is N-LASF44. After rinsing the glass substrate with distilled water and ethanol, soak it in isopropanol for one night. Prepare the scattering layer on the glass substrate. The scattering layer is composed of a luminescent material layer and a binary doping layer. The luminescent material layer is prepared by thermal resistance evaporation on the surface of the glass substrate. The material is Alq 3 , the thickness is 12nm, and the binary doped layer is prepared by electron beam evaporation on the surface of the luminescent material layer, and the material is CaO:Re 2 o 7 , CaO and Re 2o 7 The mass ratio is 5:1 and the thickness is 150nm. Then ITO is prepared on the scattering layer with a th...

Embodiment 2

[0068] The structure prepared in this example is glass substrate / DCJTB / CaCl 2 :ReO 2 / IZO / MoO 3 / NPB / ADN / TAZ / Cs 2 CO 3 / Au organic electroluminescent devices.

[0069] The glass substrate is N-LAF36. After rinsing the glass substrate with distilled water and ethanol, soak it in isopropanol for one night to prepare a scattering layer on the glass substrate. The scattering layer is composed of a luminescent material layer and a binary doping layer. The luminescent material layer is prepared by thermal resistance evaporation on the surface of the glass substrate. The material is DCJTB with a thickness of 50nm. The binary doped layer is prepared by electron beam evaporation on the surface of the luminescent material layer. The material is CaCl 2 :ReO 2 , CaCl 2 with ReO 2 The mass ratio is 4:1 and the thickness is 300nm. Then IZO is prepared on the scattering layer with a thickness of 80nm, which is prepared by magnetron sputtering; the hole injection layer is evaporated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com