UV-curing micro-nano-structure template-splicing device and template-splicing process

A micro-nano structure, ultraviolet technology, applied in the direction of photo-plate-making process of pattern surface, photo-plate-making process exposure device, micro-lithography exposure equipment, etc., can solve the problems of template damage, high working temperature, long working cycle, etc., to achieve Reduce the difficulty of demoulding, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

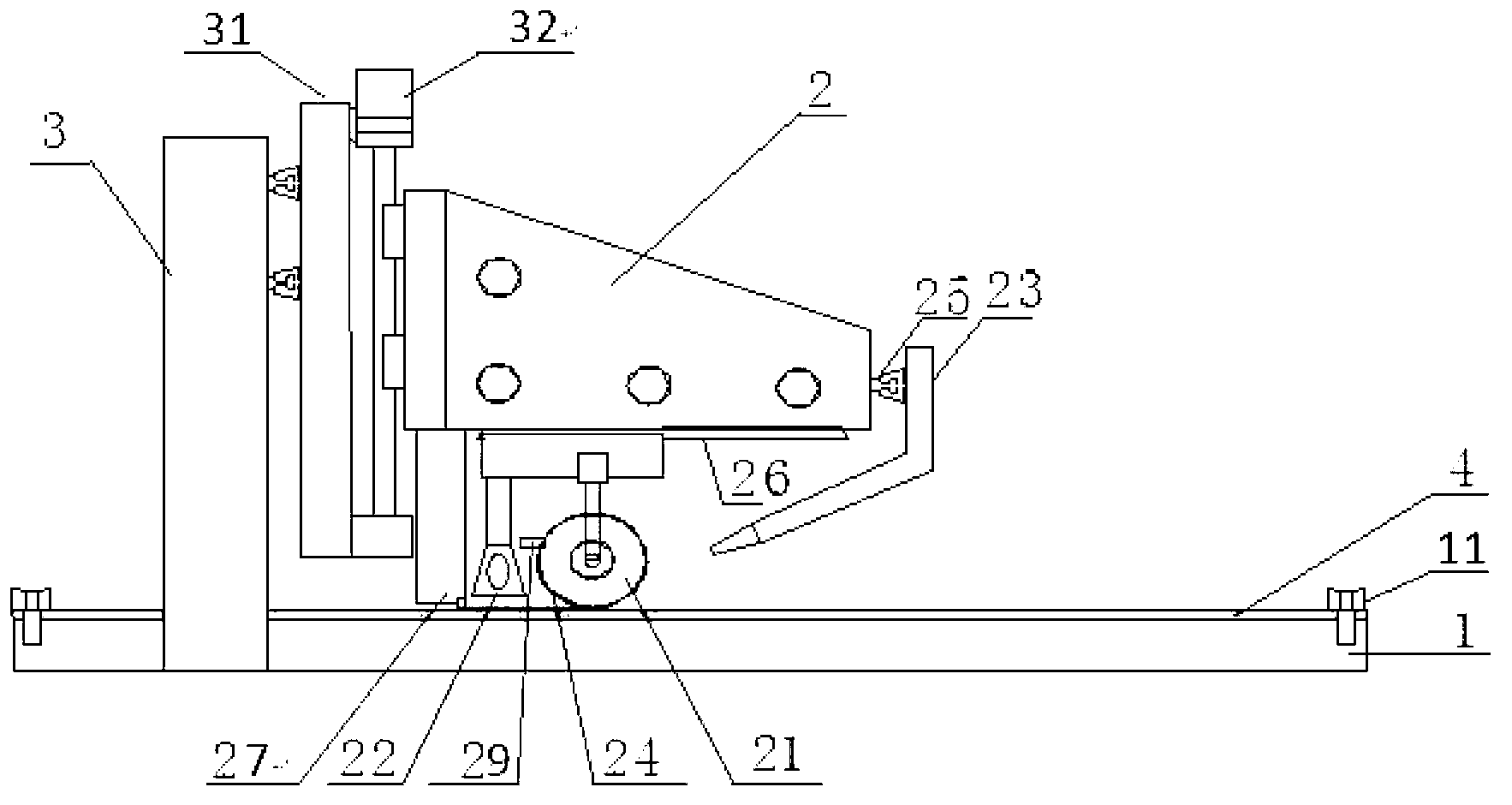

[0033] As mentioned in the background technology, in the prior art, the embossing imposition equipment using hot pressing mode, because in the embossing process, the substrate to be embossed needs to be placed in a high-temperature and high-pressure environment, which is easy to form the template and embossed graphics. damage. The imposition equipment based on the UV curing working method, because it uses the flat-to-flat step-by-step imprinting method, is prone to problems such as air bubbles and difficulty in demoulding when dealing with large-area imprinting.

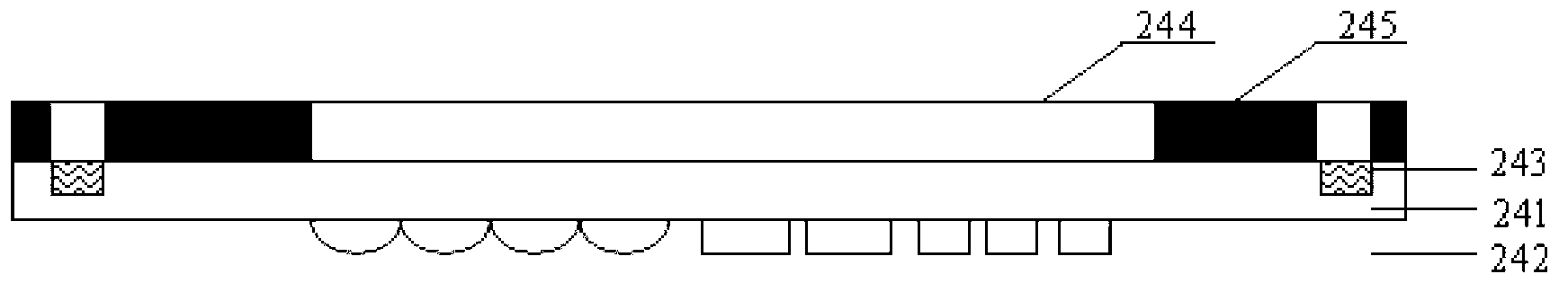

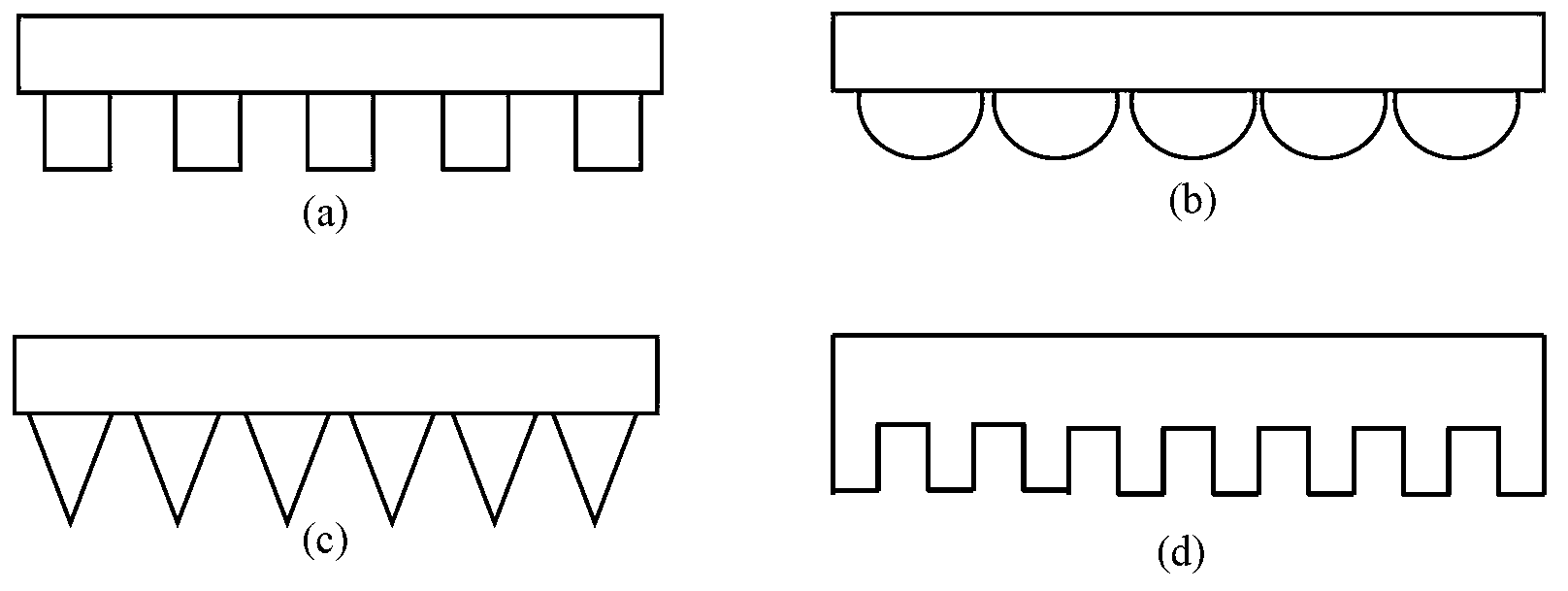

[0034]In order to overcome the above-mentioned problems, the present invention proposes a brand-new micro-nano structure imposition device in the form of ultraviolet curing and a nano-structure manufacturing method using the device. The imposition device adopts the method of roller embossing, and realizes making nano-patterns on the substrate by equipping the pressing roller with a soft stamper, and realizes splicing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com