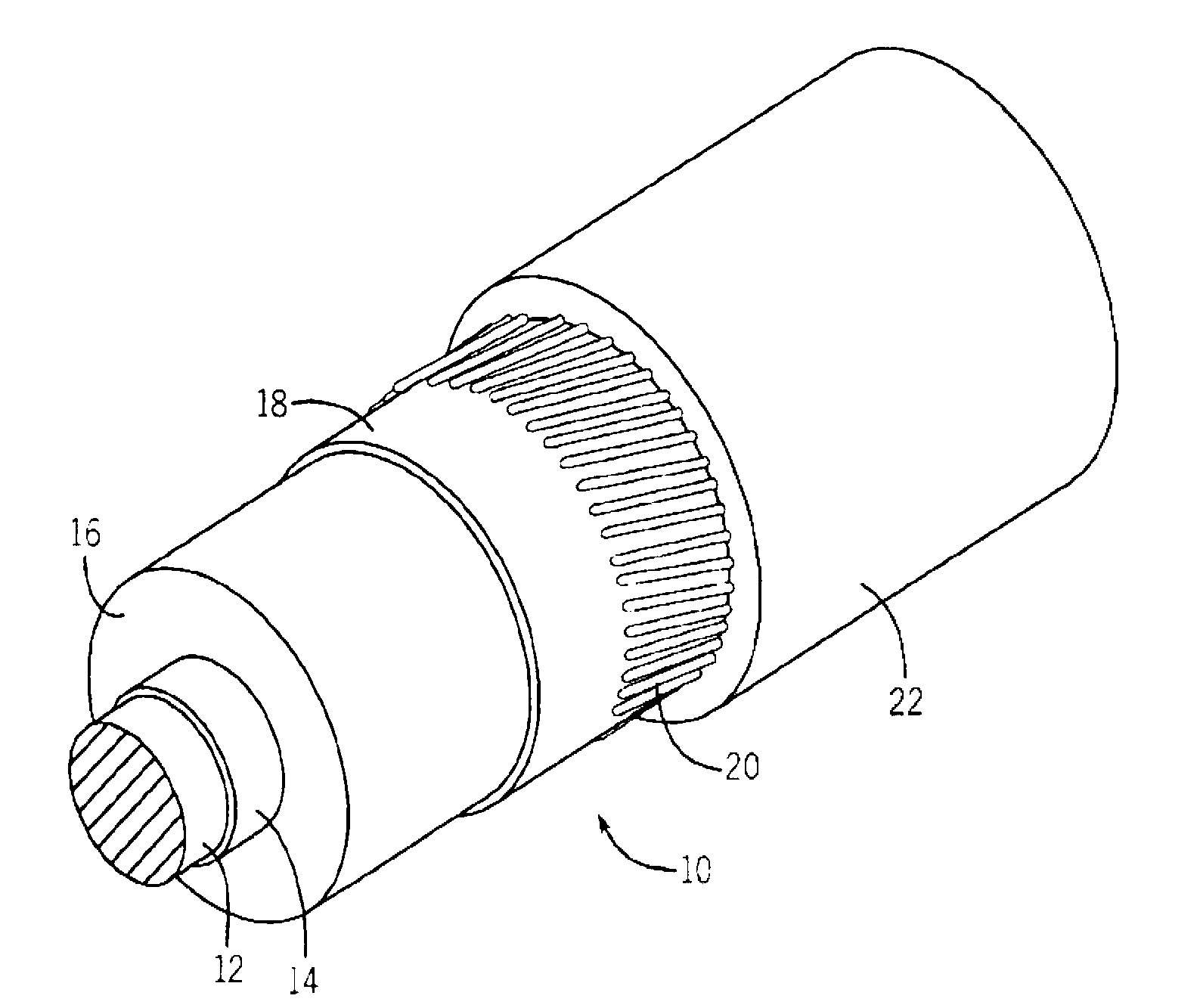

Coated conductor with voltage stabilized inner layer

A technology for conductors and inner layers, applied in the field of polymer compositions, can solve problems such as poor compatibility, and achieve the effect of improving compatibility and reducing voltage stabilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

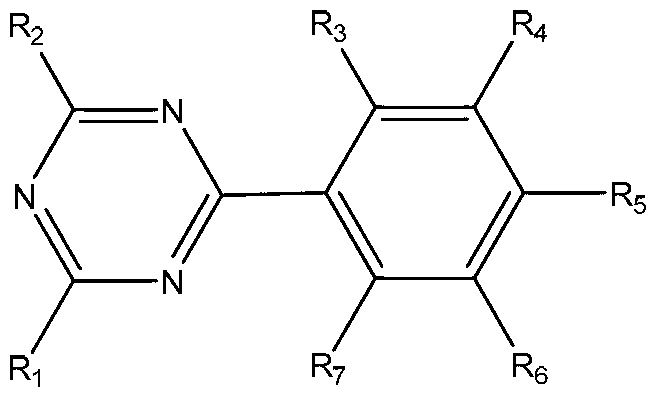

[0087] Embodiment 1 contains 1.4% by weight 2-[4,6-bis(2,4-xylyl)-1,3,5-triazin-2-yl]-5-(octyloxy)phenol (CAS2725-22-6, available LDPE from Cytec Industries).

Embodiment 2

[0088] Embodiment 2 contains 2.8% by weight LDPE.

[0089] Comparative Sample A is LDPE without voltage stabilizer mixed at a temperature of 140°C.

[0090] Comparative Sample B is LDPE with 1 wt% Chimassorb 944, a hindered amine stabilizer.

[0091] Comparative Sample C is LDPE with 1% by weight Cyassorb UV-3346, a light stabilizer.

[0092] Comparative sample A (CS-A)

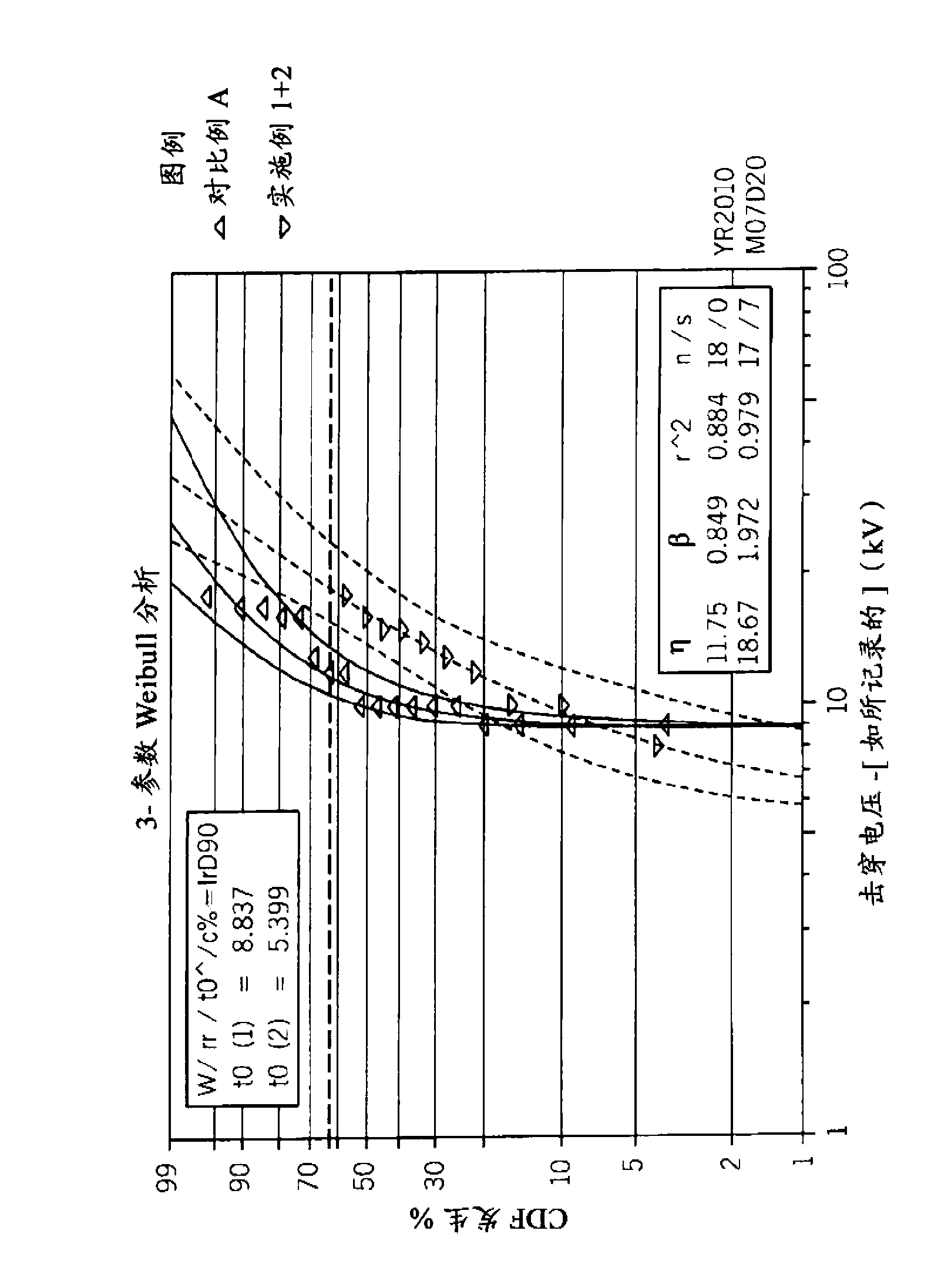

[0093] A series of 18 samples of Comparative Sample A was fitted with a 2-parameter Weibull failure distribution. Its data exhibited significant non-linearity, resulting in a poor correlation (r^2 of 0.75). A 3-parameter Weibull failure distribution was found to be more suitable for describing the failure distribution (r^2 is 0.88), offset t0=8.8kV. It was determined that the 3-parameter Weibull characteristic voltage of comparative sample A was 11.7kV, and its 90% confidence interval was 10.7-13.7kV.

[0094] Comparative sample B (CS-B)

[0095] The composition of Comparative Sample B was prepared in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com