Method and device for improving heat release efficiency of heating wire by utilizing laser texturing processing

A heating wire and texturing technology, applied in the field of laser texturing to improve the heat release efficiency of the heating wire, can solve the problems of difficult to obtain consistent micro-nano structure, material change, melting, etc., to increase the surface area and release heat. The effect of improved performance and increased heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

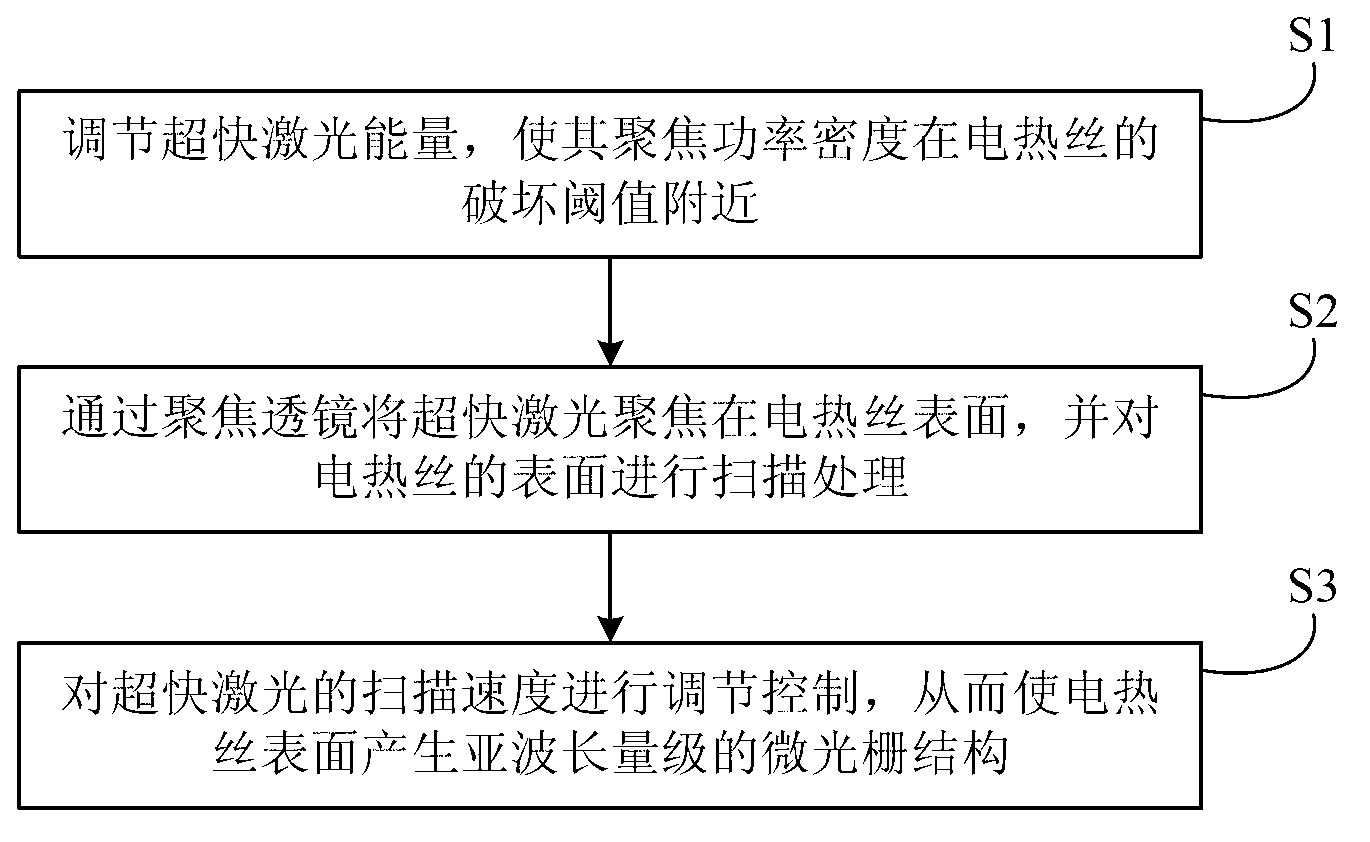

[0027] like figure 1 As shown, the present invention provides a method of using laser texturing to improve the heat release efficiency of the heating wire, comprising the following steps:

[0028] S1. Adjust the ultrafast laser energy so that the focus power density is near the destruction threshold of the heating wire;

[0029] Specifically, the single pulse energy after the ultrafast laser is emitted is adjusted to 300-500uJ by a laser energy regulator.

[0030] The ultrafast laser has a pulse width of femtosecond to picosecond level, and uses a femtosecond laser with a wavelength of 800nm, a pulse width of 100fs, a repetition rate of 1kHz, and a maximum single pulse energy of 3mJ for texturing.

[0031] S2. Focus the ultrafast laser on the surface of the heating wire through the focusing lens, and scan the surface of the heating wire.

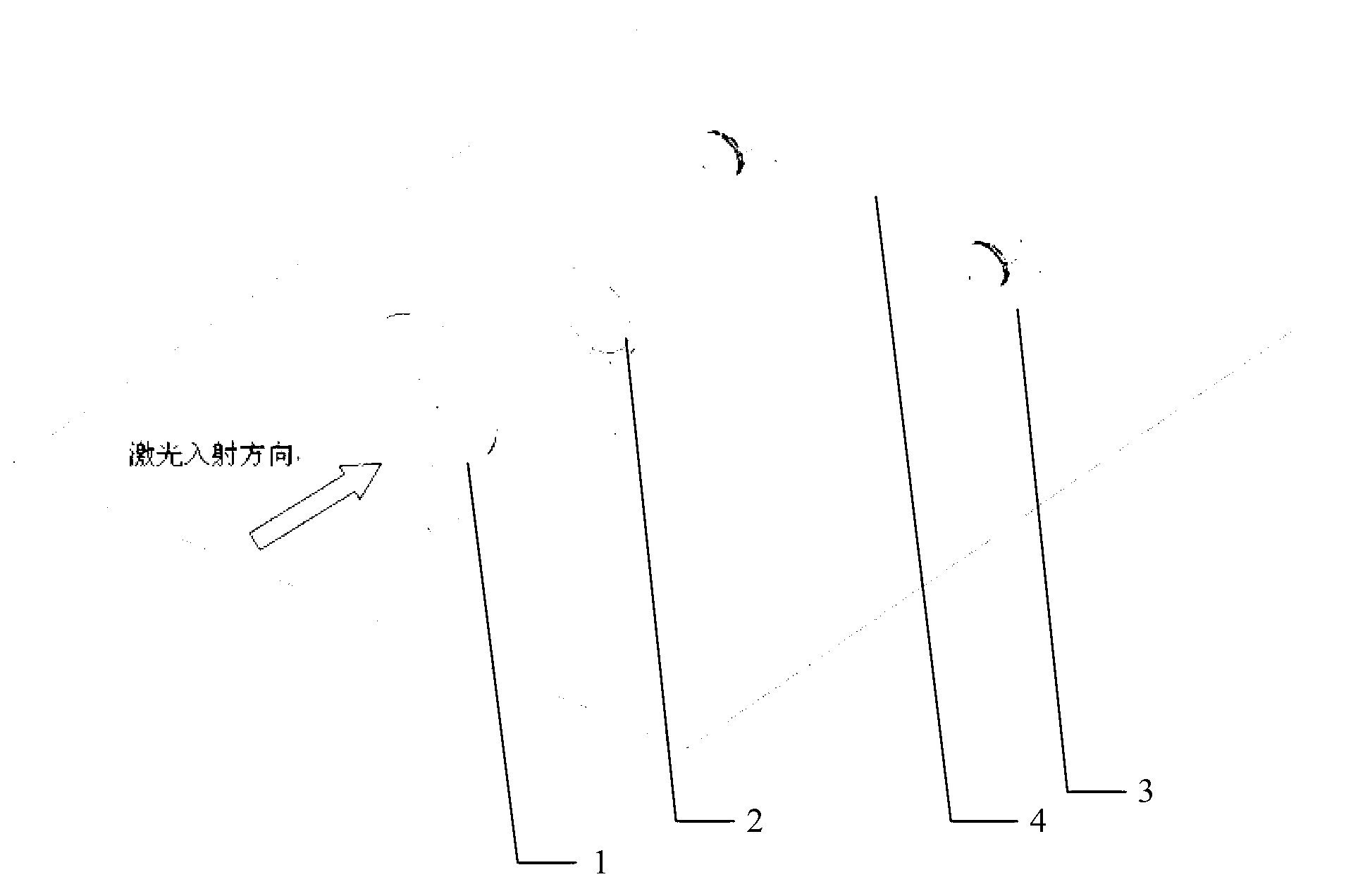

[0032] Specifically, the lens is a single lens or a cylindrical lens. In this embodiment, the lens is a cylindrical lens with a focal len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com