Preparation method of pomegranate seed oil

A pomegranate seed oil and pomegranate seed technology, which is applied in the field of pomegranate seed oil preparation by pressing, can solve the problems of heavy isomerization of punicic acid, affecting the nutritional value of products, and difficult control of processing temperature, etc., achieving less impurities and low production costs , to control the effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

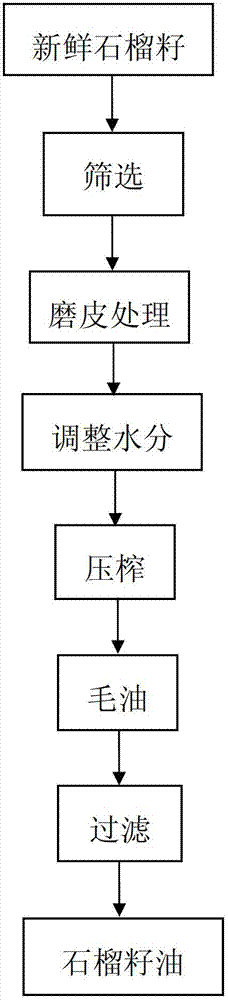

Method used

Image

Examples

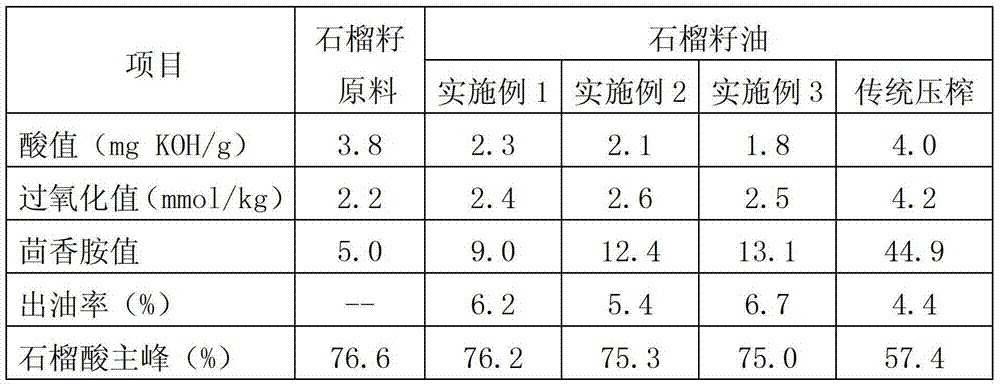

Embodiment 1

[0035] (1) Select high-quality and qualified fresh pomegranate seeds to remove impurities, moldy and deteriorated pomegranate seeds;

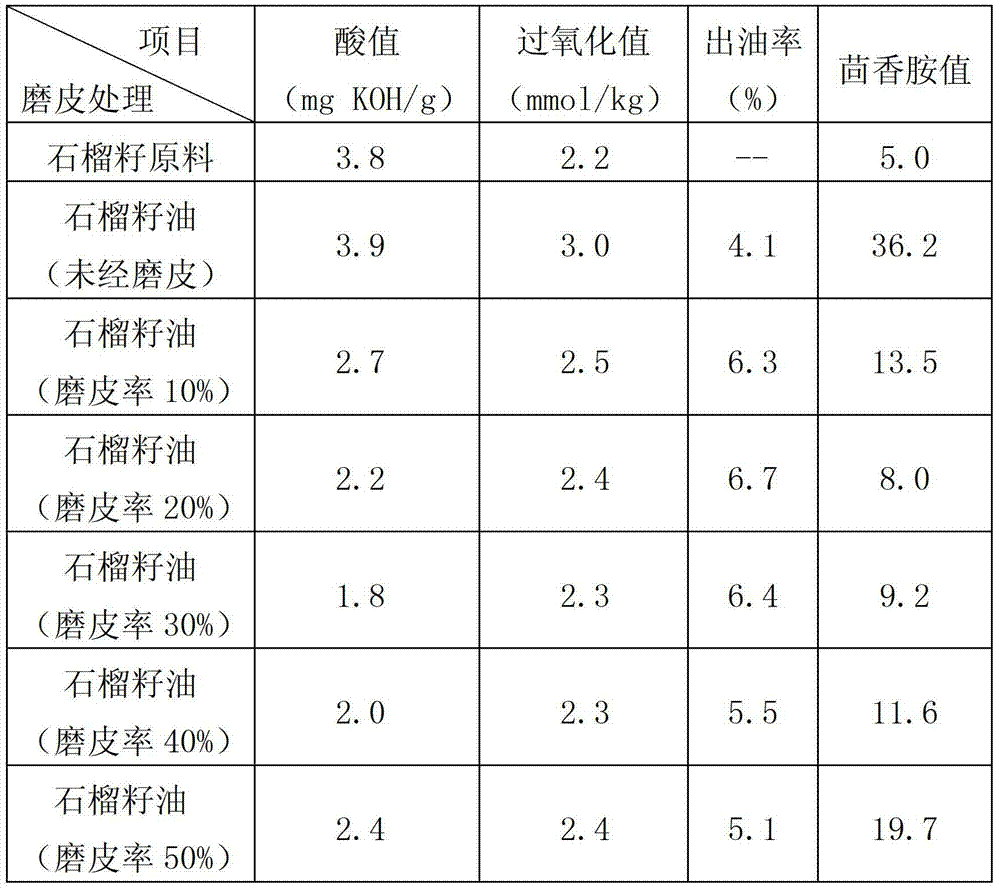

[0036] (2) Grind the screened pomegranate seeds with a machine to remove 15% of the epidermis to obtain the peeled pomegranate seeds;

[0037] (3) Sprinkle pure water evenly into the peeled pomegranate seeds, and adjust the moisture content of the pomegranate seeds to 10wt%;

[0038] (4) Put the moisture-adjusted pomegranate seeds into the preheated screw press for pressing, adjust the adjusting screw of the press, slowly adjust the thickness of the cake to 2-3mm, and start the cooling water cycle of the press to reduce the pressing temperature Control at 70°C to obtain crude oil;

[0039] (5) Add 1% diatomaceous earth accounting for the total weight of the crude oil to the crude oil, stir to disperse evenly in the crude oil, pump it into the plate and frame filter, and carry out circulating filtration until clarification, the filter pressure ...

Embodiment 2

[0042] (1) Select high-quality and qualified fresh pomegranate seeds to remove impurities, moldy and deteriorated pomegranate seeds;

[0043] (2) Grind the screened pomegranate seeds with a machine to remove 40% of the epidermis to obtain the peeled pomegranate seeds;

[0044] (3) Sprinkle pure water evenly into the peeled pomegranate seeds, and adjust the moisture content of the pomegranate seeds to 5wt%;

[0045] (4) Put the moisture-adjusted pomegranate seeds into the preheated screw press for pressing, adjust the adjusting screw of the press, slowly adjust the thickness of the cake to 2-3mm, and start the cooling water cycle of the press to reduce the pressing temperature Control at 80°C to obtain crude oil;

[0046] (5) Add 1.5% diatomaceous earth to the crude oil, stir to disperse evenly in the crude oil, pump it into the plate and frame filter, and carry out circulating filtration until clarification, with a filtration pressure of 0.3MPa. Get pomegranate seed oil.

...

Embodiment 3

[0049] (1) Select high-quality and qualified fresh pomegranate seeds to remove impurities, moldy and deteriorated pomegranate seeds;

[0050] (2) Grind the screened pomegranate seeds with a machine to remove 25% of the epidermis to obtain the peeled pomegranate seeds;

[0051] (3) Sprinkle pure water evenly into the peeled pomegranate seeds, and adjust the moisture content of the pomegranate seeds to 15wt%;

[0052] (4) Put the moisture-adjusted pomegranate seeds into the preheated screw press for pressing, adjust the adjusting screw of the press, slowly adjust the thickness of the cake to 2-3mm, and start the cooling water cycle of the press to reduce the pressing temperature Control at 90°C to obtain crude oil;

[0053] (5) Add 2% diatomite accounting for the total weight of the crude oil to the crude oil, stir to disperse it evenly in the crude oil, pump it into the plate and frame filter, and carry out circulating filtration until clarification, the filter pressure is 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com