Black Mn-Fe-P-B composite plating solution as well as using method and film layer formed by solution

A technology of mn-fe-p-b and composite plating solution, applied in the field of surface treatment, can solve problems such as environment and problem hazards, and achieve the effect of avoiding environmental pollution and improving production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

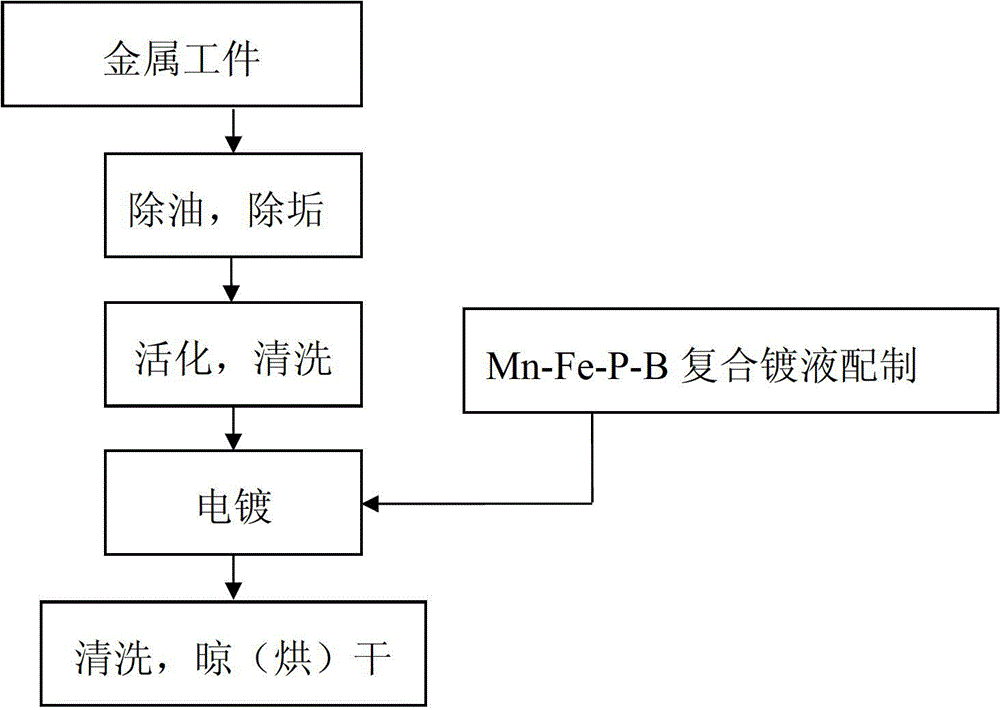

Method used

Image

Examples

Embodiment 1

[0050] The present invention adopts the following steps in order to obtain a Mn-Fe-P-B coating with a first-grade adhesion force on the 45# steel workpiece and a resistance to the neutral salt spray test (NSS) performed by the GB / T 10125-1997 standard for 131 hours:

[0051] (a) Degrease, descale, activate and clean the workpiece made of 45# steel;

[0052] (b) Prepared to contain 80-100 g / L of manganese dihydrogen phosphate, 20-40 g / L of potassium fluoroborate, 150-200 g / L of ferric sulfate, 3-5 g / L of glycine, and Pingpingjia O-20 1 ~3 g / L, sodium dodecyl sulfonate 0.5~1 g / L, sulfuric acid to adjust the pH to 3~4; the process conditions of the workpiece are: the temperature condition is normal temperature, the pulse width is 100 μs, and the cycle is 1000μs single pulse current, its average current density is 7A / dm 2 , voltage 8.6V, electroplating time is 10 minutes.

[0053] (c) After the electroplating is completed, take it out, wash it and dry it.

Embodiment 2

[0055]The present invention adopts the following steps in order to obtain a Mn-Fe-P-B coating on the Zl101 workpiece with a level 1 adhesion and a neutral salt spray test (NSS) resistance of 124 hours according to the GB / T 10125-1997 standard:

[0056] (a) Degrease, descale, activate and clean the Zl101 workpiece;

[0057] (b) Using the acidic copper sulfate electroplating process, pre-plating on the workpiece for 30 minutes and cleaning it;

[0058] (c) Prepared to contain 80-100 g / L of manganese dihydrogen phosphate, 20-40 g / L of potassium fluoroborate, 150-200 g / L of ferric sulfate, 3-5 g / L of glycine, and Pingpingjia O-20 1 ~3 g / L, sodium dodecyl sulfonate 0.5~1 g / L, sulfuric acid to adjust the pH to 3~4; the process conditions of the workpiece are: the temperature condition is normal temperature, the pulse width is 100 μs, and the cycle is 1000μs single pulse current, its average current density is 7A / dm 2 , voltage 8.6V, electroplating time is 10 minutes.

[0059] (d)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com