Air inflow filling amount forming system for dual-fuel homogenizing compression-ignition engine

A technology of homogeneous compression ignition and intake air charge, which is applied in the direction of combustion engine, internal combustion piston engine, charging system, etc., and can solve the problem that the intake air temperature cannot meet the operating requirements, the influence of the formation of homogeneous mixture, and the fuel injector Far angle and other problems, to achieve the effect of simple structure, reduce heat loss, and adjust fuel properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

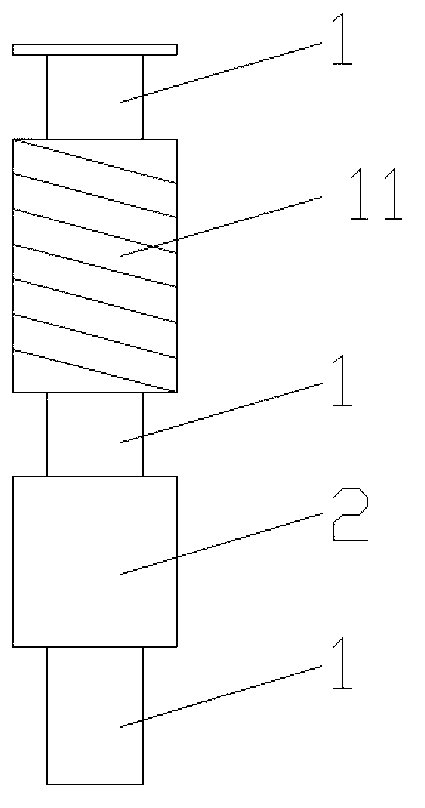

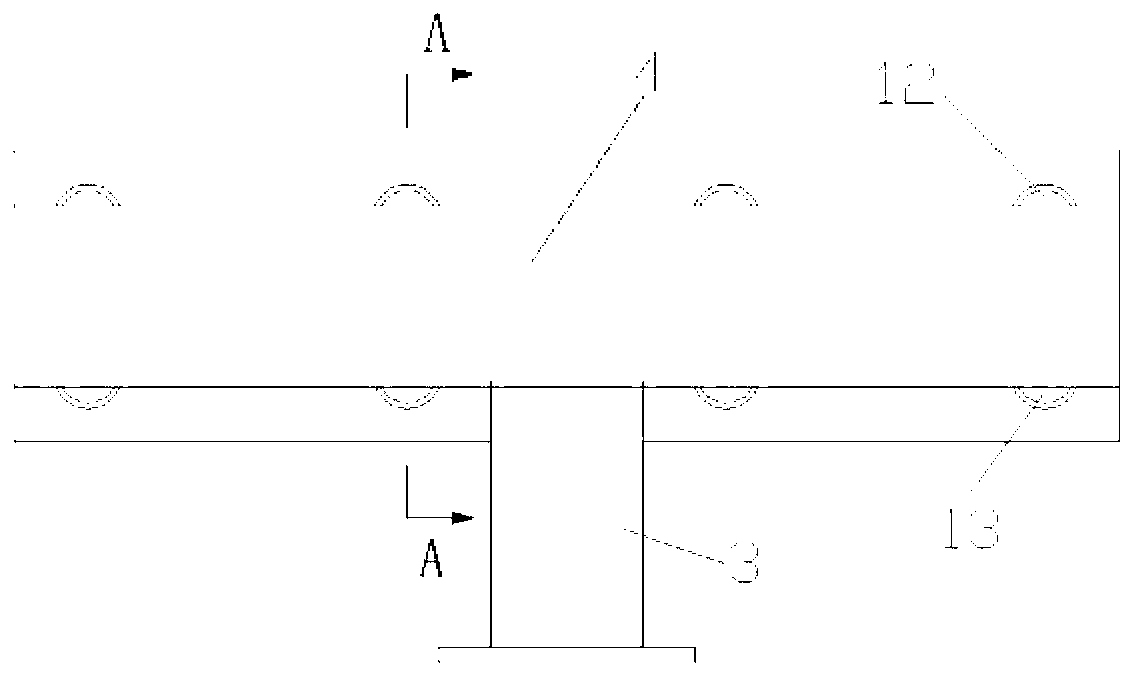

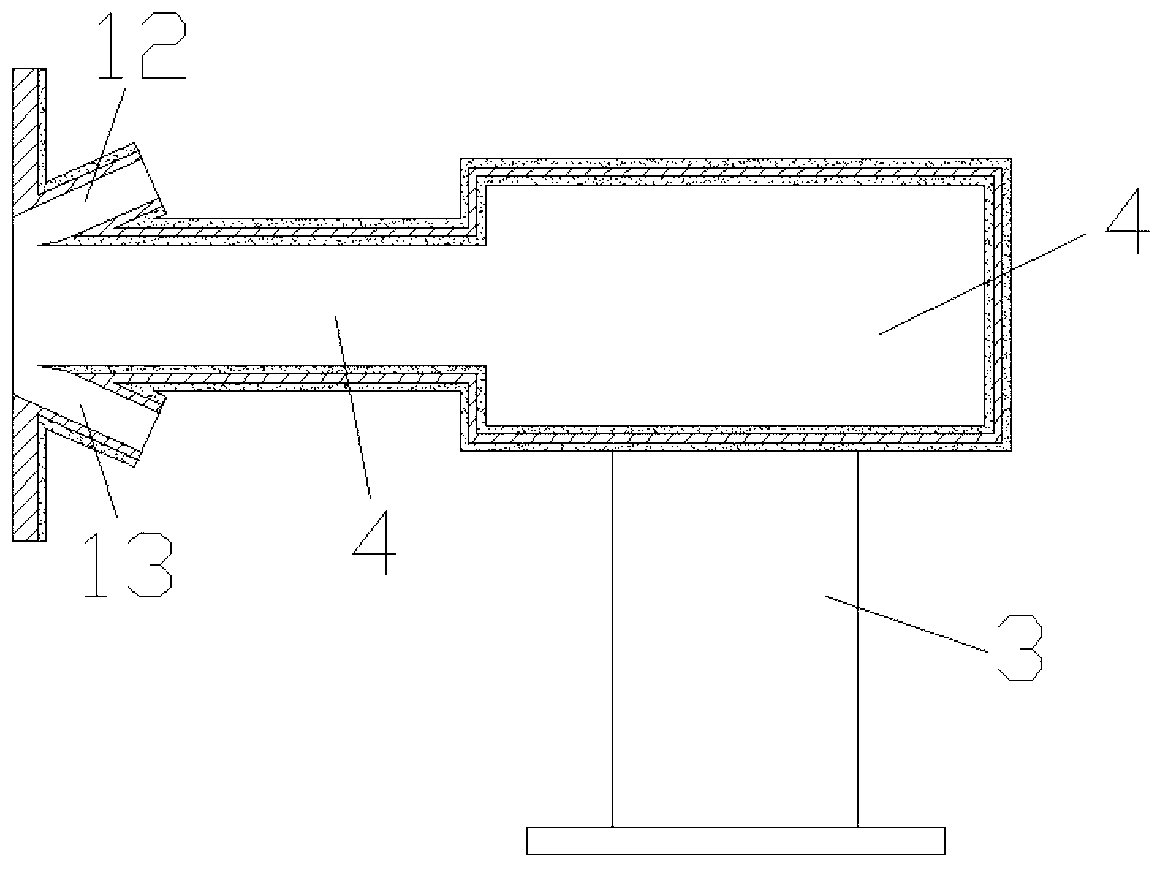

[0018] Such as Figure 1 to Figure 6 As shown, the present invention includes a front intake pipe 1, an air filter 2, a rear intake pipe 3, an intake manifold 4, a first fuel tank 5, a first oil filter 6, a first fuel consumption meter 7, a first oil pump 8, a first Fuel rail 9, first injector 10, heater 11, first injector base 12, second injector base 13, second fuel tank 14, second oil filter 15, second fuel consumption meter 6, second Oil pump 17, the second fuel rail 18, the second fuel injector 19, stainless steel 20 and zirconia insulation layer 21, the air outlet of the front air intake pipe 1 is connected with the air inlet of the rear air intake pipe 3, and the air outlet of the rear air intake pipe 3 is connected with the air inlet of the air intake pipe 3. The air inlets of the air manifold 4 are connected, the air filter 2 is installed on the front intake pipe 1, the first fuel tank 5, the first oil filter 6, the first fuel consumption meter 7, the first oil pump 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com