Optical-fiber laser for fixed-point scanning based on wavelength feedback

A fiber laser and wavelength technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of occupying system resources, slowing sampling frequency, and reducing sampling accuracy, so as to save system resources, increase sampling frequency and Accurate, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

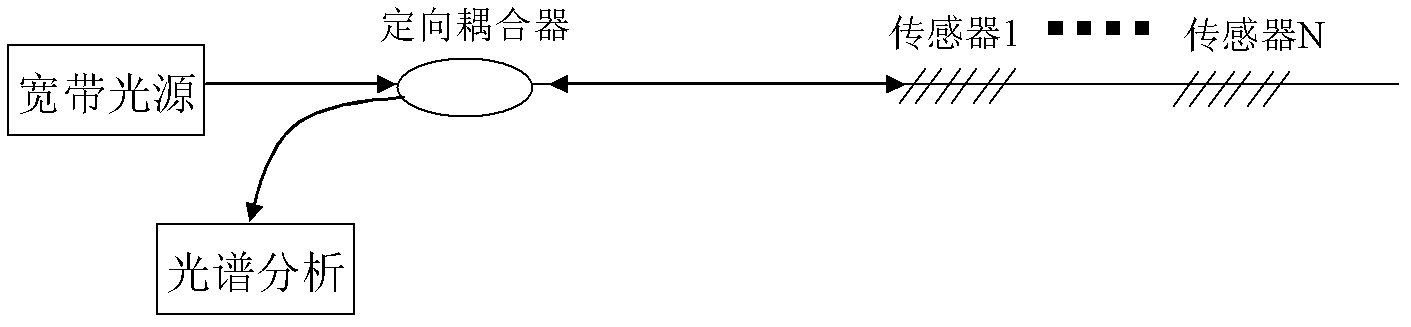

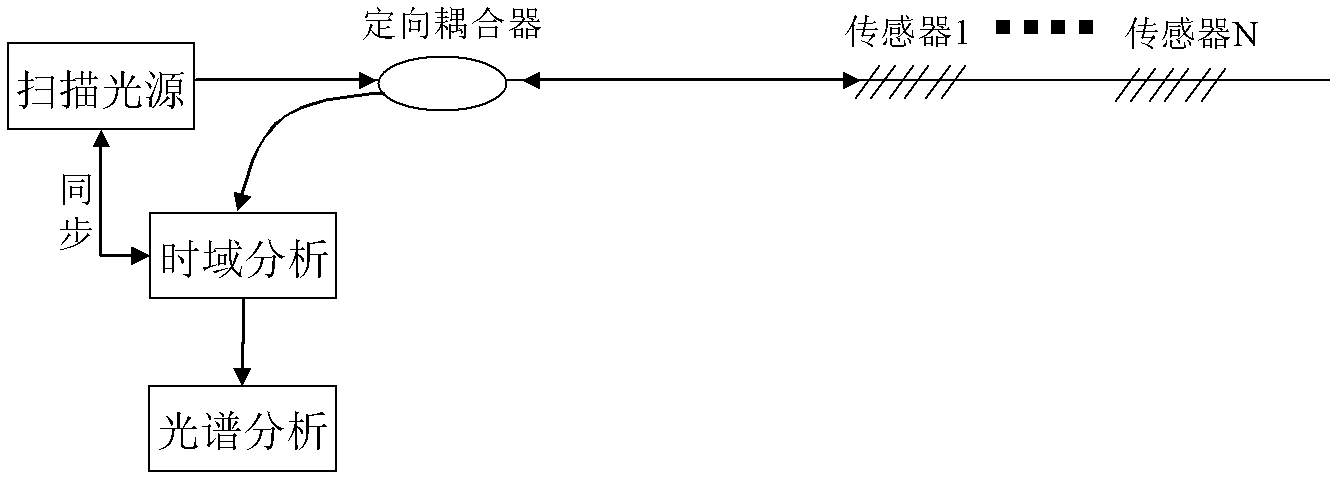

[0028] see figure 1 Shown is a schematic structural diagram of the fixed-point scanning fiber laser based on wavelength feedback of the present invention.

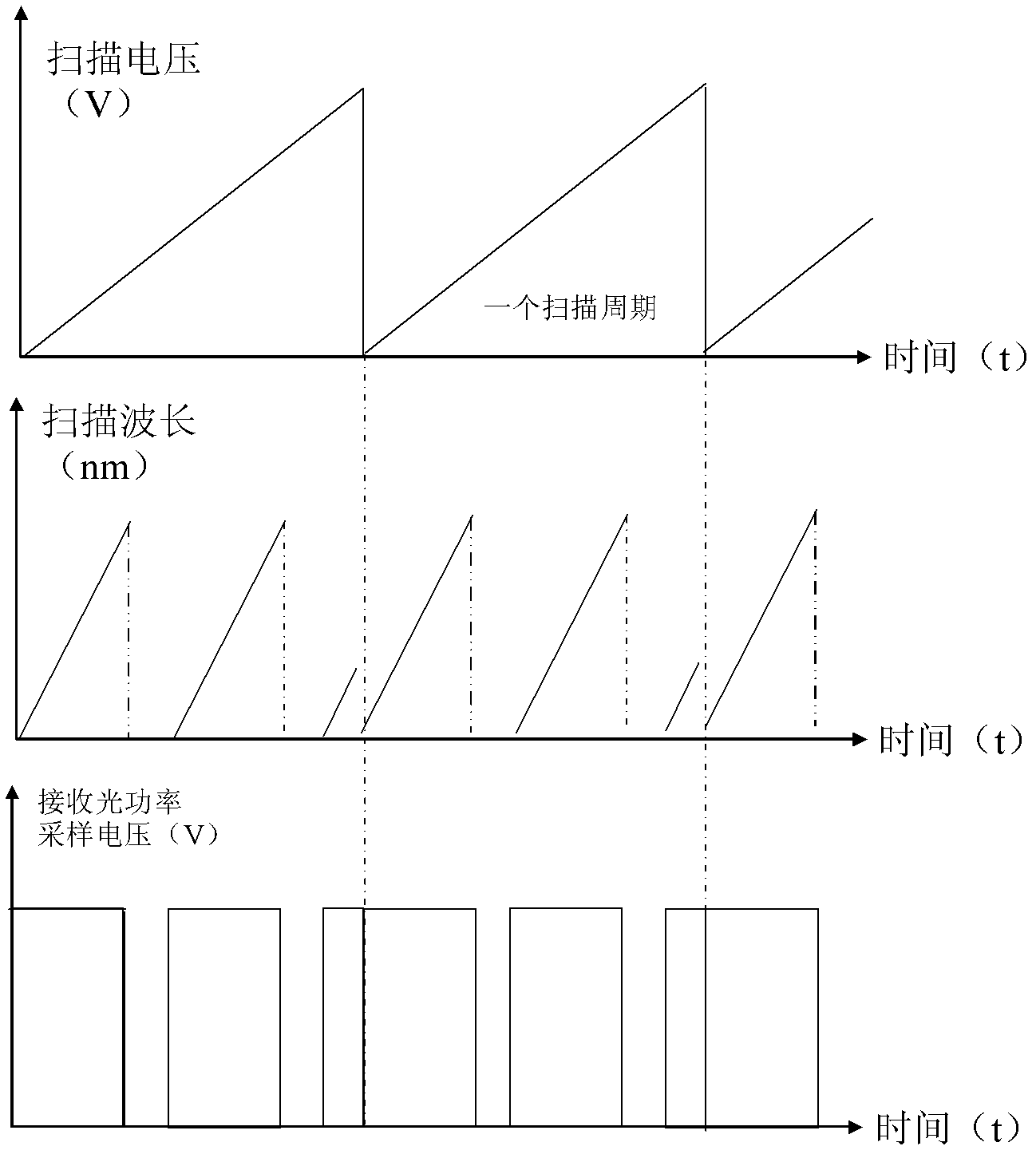

[0029] In one embodiment, the fixed-point scanning fiber laser based on wavelength feedback includes a scanning light source, a second directional coupler, a bandpass filter and a wavelength feedback loop, and the output end of the second directional coupler is the Scan laser output. Wherein, the band-pass filter is connected between the output end of the scanning light source and the second directional coupler, and the wavelength range of the band-pass filter is slightly narrower than the output light wavelength of the scanning light source scope. The wavelength feedback loop includes a sequentially connected photoelectric converter, a level discrimination module and a scanning range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com