Preparation method of catalyst for hydrogenation of phthalic acid dicarboxylic ester

A technology of phthalic acid dicarboxylate and hydrogenation catalyst, applied in the field of catalysis, can solve the problems of low reaction conversion rate, difficult catalyst preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

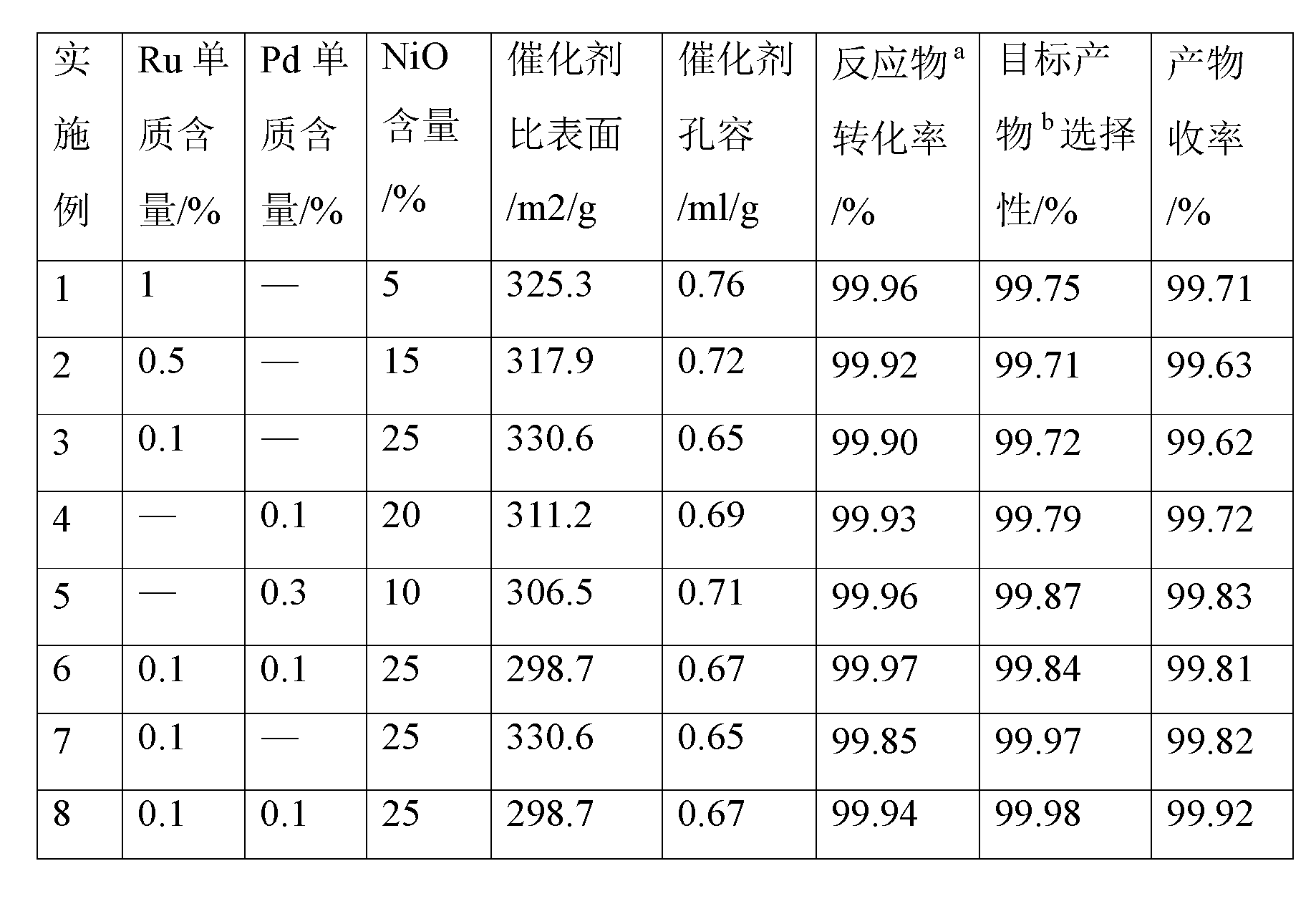

Examples

Embodiment 1

[0031] Amorphous silicon aluminum powder (SiO 2 The content is 20%) 100g is mixed evenly with 130g of aluminum oxide powder of Shandong aluminum plant and 3.5g of celadon powder. Weigh Ni(NO 3 ) 2 .6H 2 The citric acid of O salt 34g and 3.5g is dissolved in the aqueous nitric acid solution of 4wt%. After dissolving, mix with the powder, knead for 20min, and extrude into four-leaf clover of Φ1.6. After air-drying, dry at 110°C for 12h, and bake at 550°C for 4h. SiO with a NiO content of 5% was obtained 2 -Al 2 o 3 Carrier (SiO 2 The content accounts for about 9% of the silica-alumina carrier).

[0032] Take 100g of the above-mentioned alumina-silica carrier, break the strips to 3-5mm, and dry at 110°C for 12h for later use. RuCl containing 1g Ru elemental 3 100g carrier was impregnated with an equal volume of aqueous solution, dried at 110°C after impregnated for 6h, and baked at 400°C for 3h. Prepare 1 %Ru-5%NiO / SiO 2 -Al 2 o 3 catalyst.

[0033] After the cat...

Embodiment 2

[0035] Amorphous silicon-aluminum powder (SiO 2 The content is 35%) 150g is mixed evenly with Shandong aluminum plant alumina powder 100g and 3.5g squash powder. Weigh Ni(NO 3 ) 2 .6H 2 O salt 100g and the citric acid of 3.5g, add the nitric acid aqueous solution of 180ml4wt%. After dissolving, mix with the powder, knead for 20min, and extrude into four-leaf clover of Φ1.6. After air-drying, dry at 110°C for 12h, and bake at 550°C for 4h. SiO with a NiO content of 15% was obtained 2 -Al 2 o 3 Carrier (SiO 2 The content accounts for about 15% of the silica-alumina carrier).

[0036] Take 100g of the above-mentioned alumina-silica carrier, break the strips to 3-5mm, test the water absorption and dry at 110°C for 12h for later use. RuCl containing 0.5g Ru elemental 3100g carrier was impregnated with an equal volume of aqueous solution, dried at 110°C after impregnated for 6h, and baked at 400°C for 3h. Prepared 0.5%Ru-15%NiO / SiO 2 -Al 2 o 3 catalyst.

[0037] Aft...

Embodiment 3

[0039] Amorphous silicon-aluminum powder (SiO 2 The content is 10%) 150g is mixed evenly with 100g of alumina powder of Shandong Aluminum Plant and 3.5g of scallop powder. Weigh Ni(NO 3 ) 2 .6H 2 O salt 170g and the citric acid of 3.5g, add the nitric acid aqueous solution of 185ml4wt%. After dissolving, mix with the powder, knead for 20min, and extrude into four-leaf clover of Φ1.6. After air-drying, dry at 110°C for 12h, and bake at 550°C for 4h. SiO with a NiO content of 25% was obtained 2 -Al 2 o 3 Carrier (SiO 2 The content accounts for about 6% of the silica-alumina carrier).

[0040] Take 100g of the above-mentioned alumina-silica carrier, break the strips to 3-5mm, test the water absorption and dry at 110°C for 12h for later use. RuCl containing 0.1g Ru elemental 3 100g carrier was impregnated with an equal volume of aqueous solution, dried at 110°C after impregnated for 6h, and baked at 400°C for 3h. Prepared 0.1%Ru-25%NiO / SiO 2 -Al 2 o 3 catalyst.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com