Heating equipment and heating method of cast-welding iron hard die

A heating equipment and iron technology, which is applied in the field of heating equipment for lead-acid battery casting and soldering iron hard molds, can solve the problems of secondary pollution, easy leakage, short circuit, etc., and achieve the effect of safe and reliable work and good insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

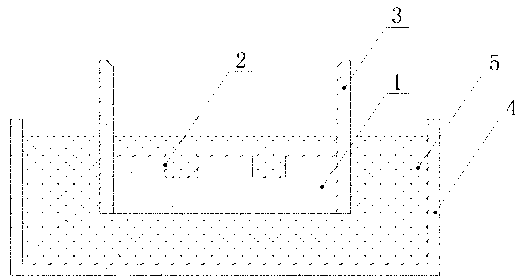

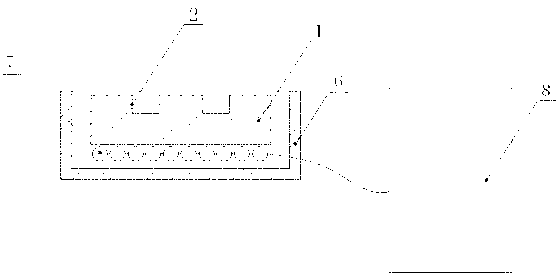

[0017] Refer to attached figure 2 In this embodiment, the casting and welding iron hard mold heating equipment includes a high-frequency induction coil 7 that can generate 20-40khz high-frequency induction magnetic force lines. The high-frequency induction coil 7 is installed on the support base 6. The high-frequency induction coil 7 It is connected with the control cabinet 8 by wires.

[0018] Cast-welding iron hard mold heating method: Take the 12 volt 20 ampere-hour lead-acid battery casting mold as an example, place the cast-welding iron hard mold body 1 provided with the cavity 2 directly above the high-frequency induction coil 7, adjust The distance between the high-frequency induction coil 7 and the cast-welded iron die body 1 is 10 millimeters, the reactance value of the high-frequency induction coil 7 is adjusted to 0.7 microhenries, and the operation of the high-frequency induction coil 7 is controlled by the control cabinet 8 . After testing, the electrothermal co...

Embodiment 2

[0020] The structure of the heating equipment is the same as in Example 1.

[0021] Cast-welding iron die heating method: adjust the reactance value of the high-frequency induction coil 7 to 0.8 microhenries; the distance between the cast-weld iron die body 1 and the high-frequency induction coil 7 is 12 millimeters. After testing, the electrothermal conversion efficiency of the high-frequency induction coil 7 is 90%; the cast-soldering iron die body 1 can be heated up to 200°C within 100 seconds; the temperature control accuracy can be controlled within the range of ±1°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com