Waterproof moisture-penetrable film, and preparation method and applications thereof

A film and mass fraction technology, applied in the field of film and its preparation, can solve the problems of poor water-repellent processing performance, difficult decomposition of PTFE, and airtight fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

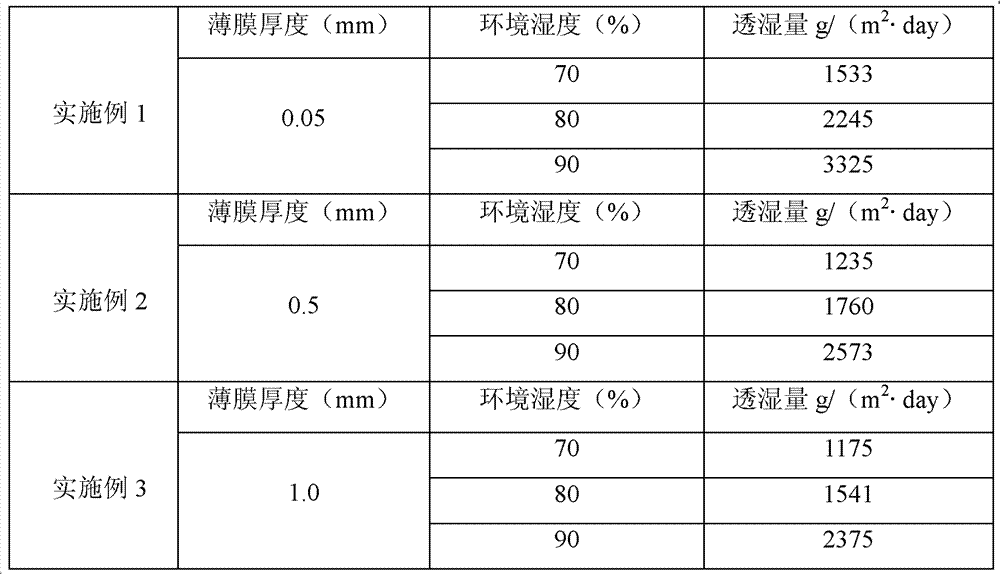

Embodiment 1

[0033] (1) Add 8 parts by mass of polyethylene glycol (molecular weight: 2000) into a three-necked flask to 100°C and vacuumize to -0.1MPa, then dehydrate at 110°C for 2 hours, then pass in nitrogen and cool to 70°C , add 17 mass parts of solvent N, N-dimethylformamide, stir evenly, and the stirring rate is 280 rpm;

[0034] (2) Then add 40 parts by mass of diphenylmethane 4,4'-diisocyanate into a three-necked flask, and react for 2 hours at a temperature of 50°C;

[0035] (3) Add 0.5 parts by mass of 1,4-butanediol and dimethylolpropionic acid of 0.5 parts by mass, stir evenly, the stirring speed is 250 rpm, after chain extension reaction for 1.5h, add 0.5 parts by mass of three Ethylamine, neutralize at 50°C for 0.5h, and finally use the solvent N,N-dimethylformamide to control the solid content of the system to 20%;

[0036] (4) Vacuumize the obtained film to remove the solvent N,N-dimethylformamide, the vacuum degree is -0.05MPa, then pour it into a petri dish, level it t...

Embodiment 2

[0038] (1) Add 30 parts by mass of polyethylene glycol into a three-necked flask to 100°C and vacuumize to -0.1MPa, dehydrate at 115°C for 2 hours, then pass in nitrogen, cool to 70°C, and add 50 parts by mass The solvent N, N-dimethylformamide, stir evenly, and the stirring rate is 300 rpm;

[0039] (2) Then add 30 parts by mass of diphenylmethane 4,4'-diisocyanate into the three-necked flask, and react for 4 hours at a temperature of 80°C;

[0040] (3) Add 1.0 parts by mass of 1,4-butanediol and 1.0 parts by mass of dimethylol propionic acid, stir evenly, the stirring speed is 280 rpm, after 2 hours of chain extension reaction; add 1 mass part of triethyl Amine, neutralization reaction at 55°C for 1 hour, and finally use the solvent N,N-dimethylformamide to control the solid content of the system to 30%;

[0041] (4) Vacuumize the obtained film to remove the solvent N,N-dimethylformamide, the vacuum degree is -0.05MPa, then pour it into a petri dish, level it to form a film...

Embodiment 3

[0043] (1) Add 50 parts by mass of polyethylene glycol into a three-necked flask to 100°C and vacuumize to -0.1MPa, dehydrate at 120°C for 2 hours, then pass in nitrogen, cool to 70°C, and add 80 parts by mass The solvent N, N-dimethylformamide, stir evenly, and the stirring rate is 350 rpm;

[0044] (2) Then add 10 parts by mass of diphenylmethane 4,4'-diisocyanate to the three-necked flask, and react for 6 hours at a temperature of 80°C;

[0045] (3) Add 1.5 parts by mass of 1,4-butanediol and dimethylol propionic acid of 1.5 parts by mass, stir evenly, the stirring rate is 300 rpm, after chain extension reaction for 2.5h; add 2 parts by mass of three Ethylamine, neutralize at 60°C for 1.0h, and finally use the solvent N,N-dimethylformamide to control the solid content of the system to 40%;

[0046] (4) Vacuumize the obtained film to remove the solvent N,N-dimethylformamide, the vacuum degree is -0.05MPa, then pour it into a petri dish, level it to form a film, and then put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com