Heat conduction diffusion sheet and preparation method thereof

A diffusion sheet and diffusion layer technology, which is applied in the direction of chemical instruments and methods, film/sheet adhesives, adhesive types, etc., can solve the problems of good metal conductivity, short circuit of electronic components, good thermal conductivity, etc. , achieving high electrical insulation, reduced contact thermal resistance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

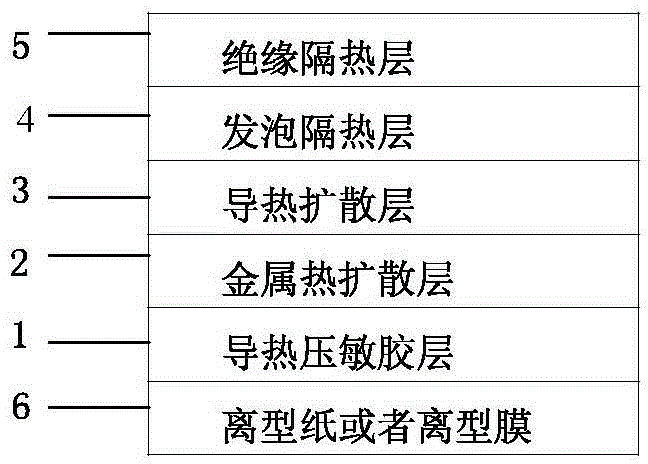

[0042] For the preparation method provided by the invention, please refer to figure 1 ,Proceed as follows:

[0043] Step 1: Coat one surface of the metal thermal diffusion layer 2 with a thermal diffusion layer 3 containing layered graphite powder, put it in a hot oven, and dry it at a temperature of 130-140°C for five minutes, let the solvent evaporate completely and completely solidify ,take out.

[0044] Wherein: the metal thermal diffusion layer 2 can be made of a metal material or an alloy material, and three thicknesses can be selected: 6um, 53um, and 100um as examples.

[0045] The heat conduction diffusion layer 3 is prepared by uniformly stirring the materials in the following parts by weight ratio:

[0046] Solvent-type liquid thermosetting acrylate resin with a solid content of 40%: curing agent: layered graphite powder = 10:1:50.

[0047] The heat conduction diffusion layer 3 can be selected from three thicknesses: 2um, 16um, and 30um, which are used as examples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com