Urea-based lubricating grease composition

A technology of urea-based grease and composition, applied in the field of grease, can solve the problems of inability to use for a long time, lubricating performance, decline in anti-wear extreme pressure performance, lack of extreme pressure and wear resistance, etc., and achieve long-term service life and long-term stability. long-term, excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

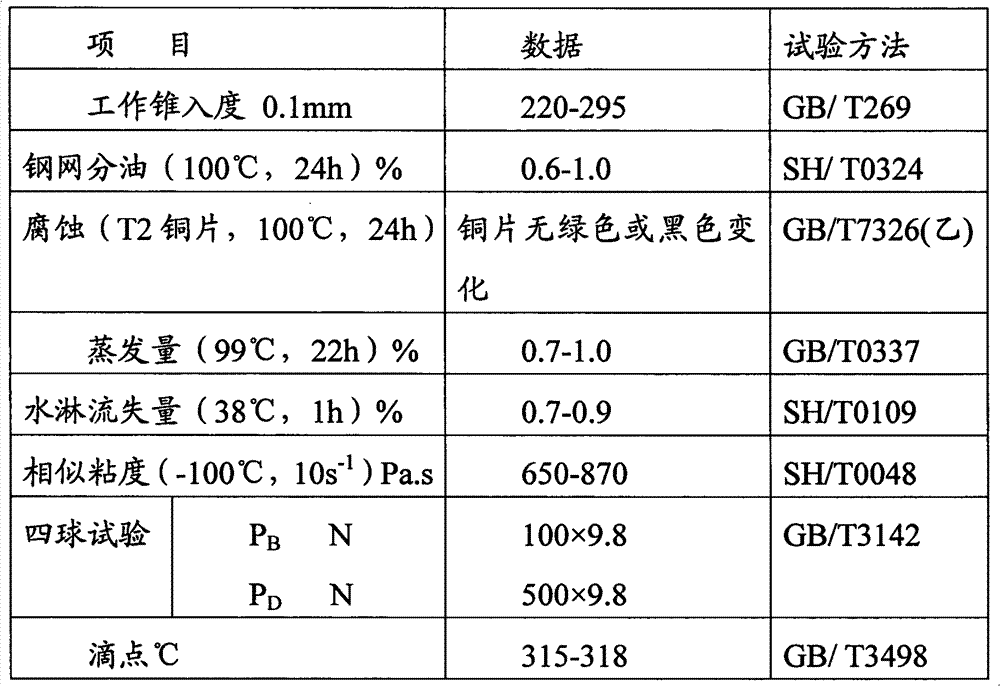

Image

Examples

Embodiment 1

[0030] Mix the raw materials according to the following weight

[0031] 150BS mechanical oil: 840kg, No. 100 mechanical oil: 210kg,

[0032] p-phenylenediamine: 30kg, cyclohexylamine: 70kg,

[0033] Diphenylamine: 7.5kg, MDI (100): 300kg,

[0034] Molybdenum carbonophosphate (T300): 30kg, primary alkyl zinc dithiophosphate (T202): 6kg;

[0035] Production method: (1) Put 20% of the total weight of base oil into the first reaction kettle, heat to 50°C, then add p-toluidine, stir and heat to 80°C, stop stirring for later use.

[0036] (2) Put the remaining base oil into the second reaction kettle and heat up to 5°C, then add MDI (100), stir and heat up to 78°C; at the same time, add cyclohexylamine to the first reaction kettle and stir for 15 minutes, Then add it all to the second reaction kettle.

[0037] (3) Stir and heat up to 130° C., then stop stirring for 5 minutes and then stir for 5 minutes, and repeat this 3 times.

[0038] (4) Keep the temperature above 130°C, tra...

Embodiment 2

[0041] Mix the raw materials according to the following weight

[0042] 150BS mechanical oil: 900kg, No. 100 mechanical oil: 225kg,

[0043] p-phenylenediamine: 45kg, cyclohexylamine: 45kg,

[0044] Diphenylamine: 3kg, MDI (100): 150kg,

[0045] Molybdenum carbonophosphate (T300): 75kg, primary alkyl zinc dithiophosphate (T202): 15kg;

[0046] Production method: (1) Put 40% of the total weight of base oil into the first reaction kettle, heat to 55°C, then add p-toluidine, stir and heat to 85°C, stop stirring for later use.

[0047] (2) Put the remaining base oil into the second reaction kettle and heat up to 5°C, then add MDI (100), stir and raise the temperature to 75°C; at the same time, add cyclohexylamine to the first reaction kettle and stir for 13 minutes, Then add it all to the second reaction kettle.

[0048] (3) Stir and heat up to 130° C., then stop stirring for 5 minutes and then stir for 5 minutes, and repeat this 3 times.

[0049] (4) Keep the temperature above...

Embodiment 3

[0051] Mix the raw materials according to the following weight

[0052] 150BS mechanical oil: 675kg, No. 100 mechanical oil: 450kg,

[0053] p-phenylenediamine: 30kg, cyclohexylamine: 90kg,

[0054] Diphenylamine: 9kg, MDI (100): 270kg,

[0055] Molybdenum carbonophosphate (T300): 30kg, primary alkyl zinc dithiophosphate (T202): 30kg;

[0056] Production method: (1) Put 70% of the total weight of base oil into the first reaction kettle, heat to 55°C, then add p-toluidine, stir and heat to 85°C, stop stirring for later use.

[0057] (2) Put the remaining base oil into the second reaction kettle and heat up to 5°C, then add MDI (100), stir and raise the temperature to 77°C; at the same time, add cyclohexylamine to the first reaction kettle and stir for 15 minutes, Then add it all to the second reaction kettle.

[0058] (3) Stir and heat up to 130° C., then stop stirring for 5 minutes and then stir for 5 minutes, and repeat this 3 times.

[0059] (4) Keep the temperature abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com