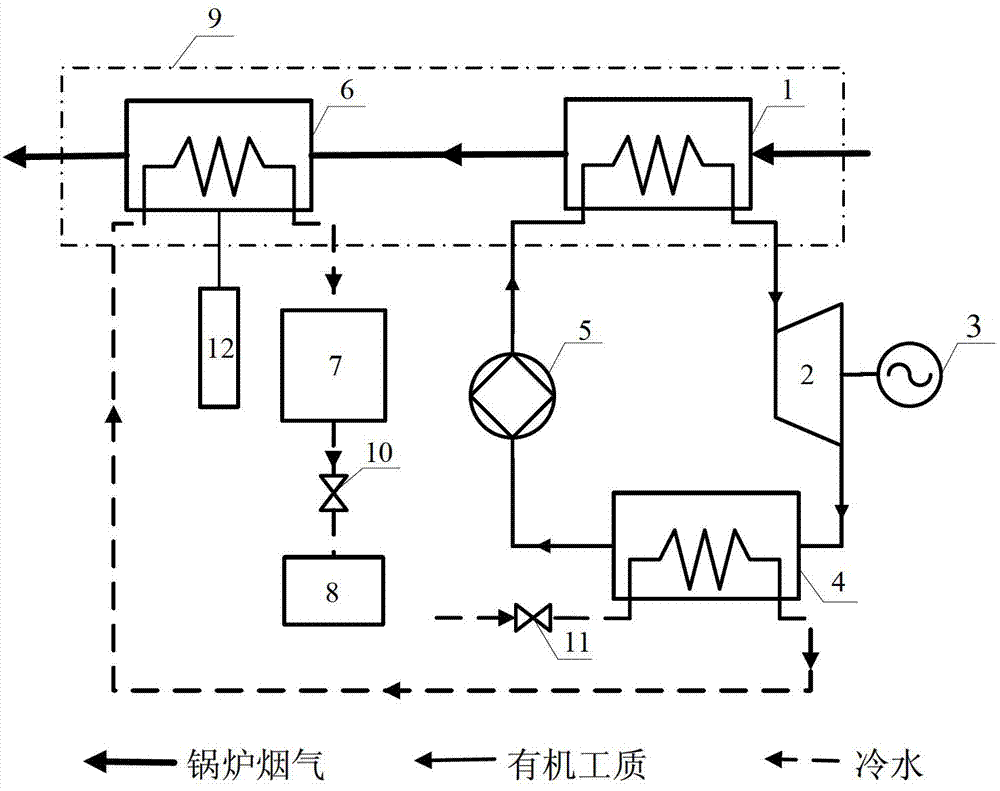

Smoke condensation heat recovery combined heat and power supply system based on organic Rankine cycle

A flue gas condensation and Rankine cycle technology, applied in air heaters, mechanical equipment, steam engine devices, etc., can solve problems such as being in the primary stage, and achieve the effects of reducing emissions, improving thermal efficiency, and being beneficial to environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

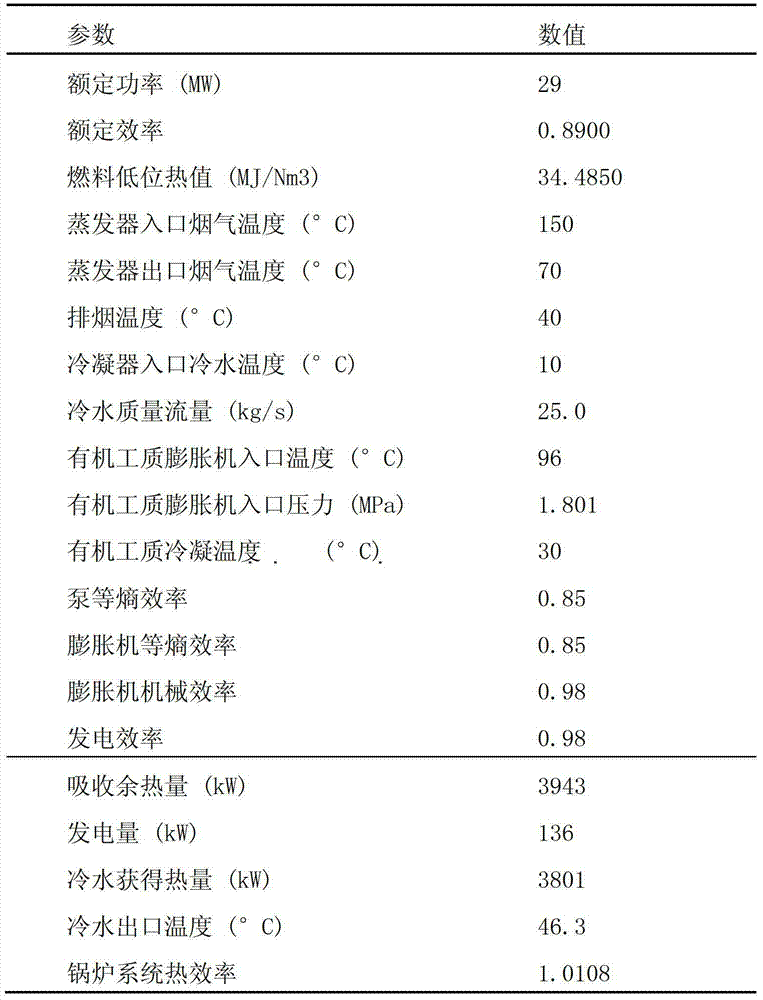

[0018] Taking the natural gas heating boiler as an example, the simulation calculation is carried out. Table 1 shows the data and calculation results used in the calculation. Among them, the organic Rankine cycle uses R600a as the working fluid, which is a subcritical cycle. It can be seen from the table that the total amount of waste heat absorbed by the device is 3943kW, and the thermal efficiency calculated by the traditional low calorific value standard is increased to 101.08%. It can be seen that the device can significantly improve the efficiency and achieve the effect of energy saving and emission reduction. At the same time, the calculation shows that in the flue gas without waste heat recovery, the mass fraction of water vapor is as high as 12.21%, the volume fraction is 18.76%, and the dew point temperature is 59.0°C. When the final discharge temperature of the flue gas drops to 40°C, the mass fraction of water vapor is 5.13%, the mass recovery rate is 61.15%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com